Shock assembly filling the shocks with oil, Assembly of the differential gear, Assembly of the bevel gear – OFNA Racing Worlds II User Manual

Page 5: Assembly of the spring

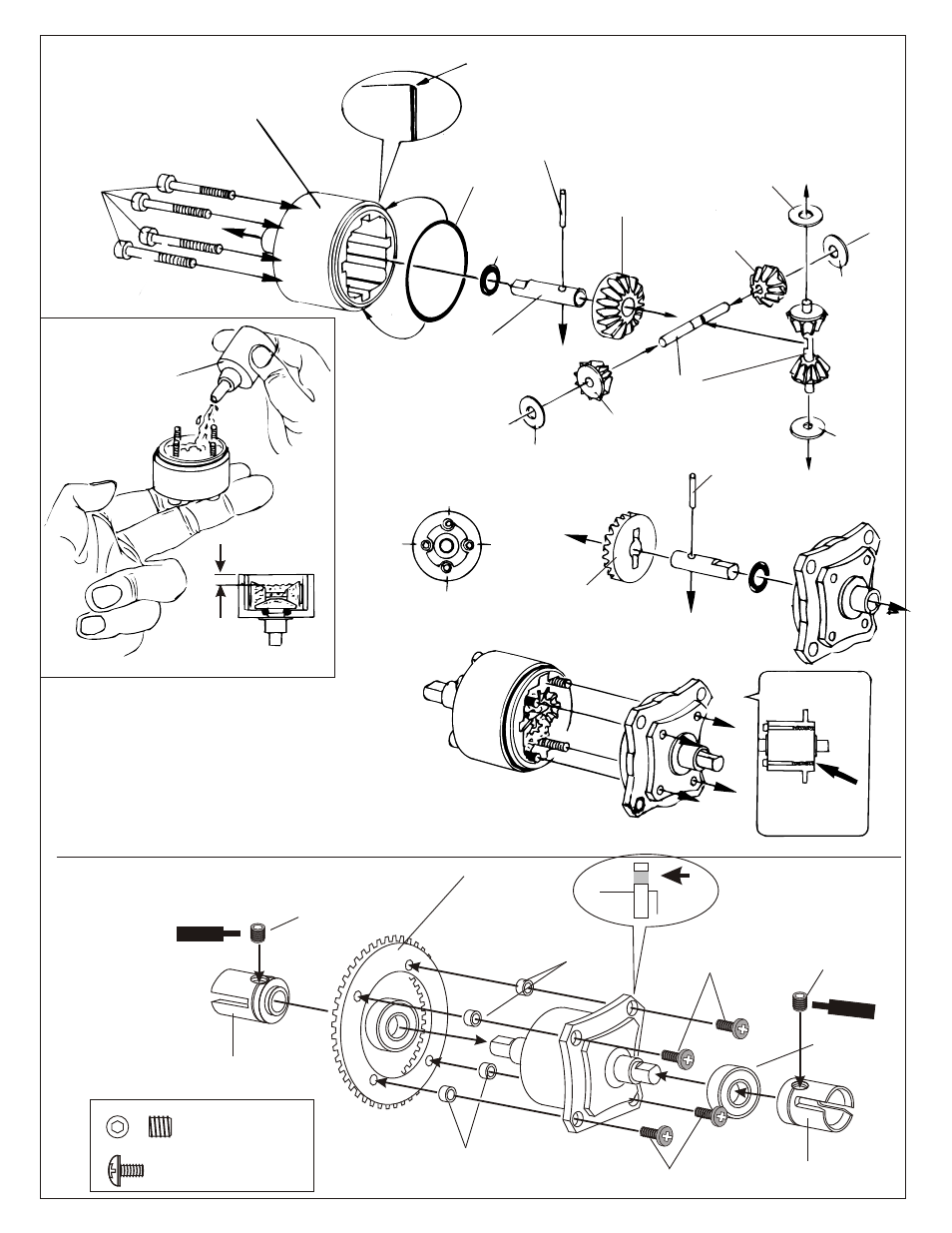

ASSEMBLY OF THE DIFFERENTIAL GEAR

#31322

Diff. Case ( Front/Rear )

#31323

Diff. Case (Center )

3 x 30mm

Cap Screw

#30779

O-Ring

#30779

0.5 x 26mm

O-Ring

#30779

2 x 12.8mm

Pin

#30779

2 x 12.8mm

Pin

#30771

Diff. Shaft

#30779

4 x 10mm

Washer

#30772

3.5mm

Cross Pin

#30770

Diff. Bevel Gear, Set

Grease

or

Silicone Oil

* Follow the number to tighten up

the screw.

* Tighten the Diff. Screws

to the end of the case

with 1 or 2 threads

* Position the O-ring as shown.

* Fill diff. Case with grease

during assembly.

ASSEMBLY OF THE BEVEL GEAR

#90026

5 x 5mm

Set Screw

#30120

Bevel Gear, 44T

Option:

#31010

HD Steel Bevel Gear, 44T

3mm

Tube

3mm

Tube

#30121

Mounting Hardware

3 x 5mm Screw & tube

3 x 5mm

Screw

#30082

Cap Joint, Long

( Build two differentials for front and rear. )

1

2

3

4

* Notice the diff case with the

straight holes are for front & rear.

5 x 5mm Set Screw

3 x 5mm Screw

* Push 3mm tubes into

holes of the diff. Case.

Screw

Cement

Screw

Cement

* Fill the diff. Case to approx 80% with

grease.

Building Notes:

• Set gear mesh in differential by tightening all four screws

until diff locks. Then loosen each screw ¼ turn. Diff should

still be hard to turn, but will smooth out after running.

If diff is too loose, the internal gears will quickly ware out

• When tightening the four screws, look for one thread

coming out of diff cover.

#30082

Cap Joint, Long

#30750

Diff Case, Bevel Gear

#30322

Diff Case, front / rear Complete

#90026

5 x 5mm

Set Screw

#30770

Diff. Bevel Gear, Set

#30770

Diff. Bevel Gear, Set

#30779

4 x 10mm

Washer

#30779

4 x 10mm

Washer

#30779

4 x 10mm

Washer

#30770

Diff. Bevel Gear, Set

Optional Silicone Oil:

#10231 - 1,000 wtg

#10232 - 3,000 wtg

#10233 - 5,000 wtg

#10234 - 7,000 wtg

#10235 - 10,000 wtg

#10236 - 30,000 wtg

#10237 - 50,000 wtg

#32237

O-Ring, rebuild

Shock Cylinder

( Make 2 for rear. )

( Make 2 for front.)

OIL

2. Pull down piston, attach pressure top

and shock oil overflow with tissue

paper.

SHOCK ASSEMBLY

FILLING THE SHOCKS WITH OIL

ASSEMBLY OF THE SPRING

1. Pull down piston and pour oil into

shock cylinder. Remove air bubbles

by slowly moving piston up and down.

3. Tighten up shock cap.

*Pull down.

*Move Slowly.

*Leave 3mm.

*Push Onto Shock

Cylinder

Shock Shaft

Piston

* Be careful not to damage shock shaft.

Pressure Top

#32044

Shock Cap, Hard Coated

*

Fit into groove.

#32203

Dust Pusher

(Yellow Rubber)

Oil Seal

* Fit into groove.

2mm

Washer

1mm

Washer

7mm

E-Ring

* E-Ring must

fit into groove as shown.

* Short shaft for front.

#32051

6mm Ball End,

Plastic parts bag

* Long shaft for rear.

2.6mm Nut

* Push 6mm ball joint

into ball end.

2.6 x 5mm

Washer

Spring Collar

Optional:

#32330

Red Spring set

#32340

Yellow Spring Set

Spring Holder

*Slide spring collar into Shock.

5mm

3mm

1mm

*Spring Tension adjust .

er

¼

u

Â

®

6mm

Ball Joint

#37380

* Screw down cap.

# 32033

* Assembly 4 pieces of the

shock Shaft .

#32291

Front, Short(w-gt) Shaft, 3.2mm

#32236

Rear, Long Shaft, 3.2mm

E-Ring

Hard Coated Shocks:

Front Super Shock, 3.2mm

# 32290

Rear Super Shock, 3.2mm

# 32230

#32051

6mm Ball End,

Plastic parts bag

Option:

#32039

O-ring Pistons

#32204

Spring Spacer Clips Set

#32051

All Plastic shock

parts bag

#30620

7 x 19x 5mm

Ballbearings

#30620

7 x 19x 5mm

Ballbearings