Operation – Ryobi AG402 User Manual

Page 9

9 - English

WARNINg

:

Always install grinding wheel and abrasive mop disc with

the depressed center against the disc flange as shown

on the opposite page. Failure to do so will cause the

grinding wheel to crack when tightening the clamp nut.

This could result in serious personal injury because of

loose particles breaking off and being thrown from the

angle grinder. Do not overtighten.

Thread the flange nut on the spindle with the flat side of nut

facing up. Fit raised, small diameter portion of the clamp

nut into the hole in the wheel and finger tighten.

To install abrasive mop disc, thread the nut on the spindle

with the flat side of flange nut facing down. Finger

tighten.

Depress and hold the spindle lock button and rotate the

wheel clockwise until the spindle locks in position.

Securely tighten the nut with the wrench provided.

Do not overtighten.

DANgER:

Never attach a wood cutting or carving blade of any type

to this angle grinder. It is only designed for grinding and

sanding. Use for any other purpose is not recommended

and creates a hazard, which will result in serious injury.

DANgER:

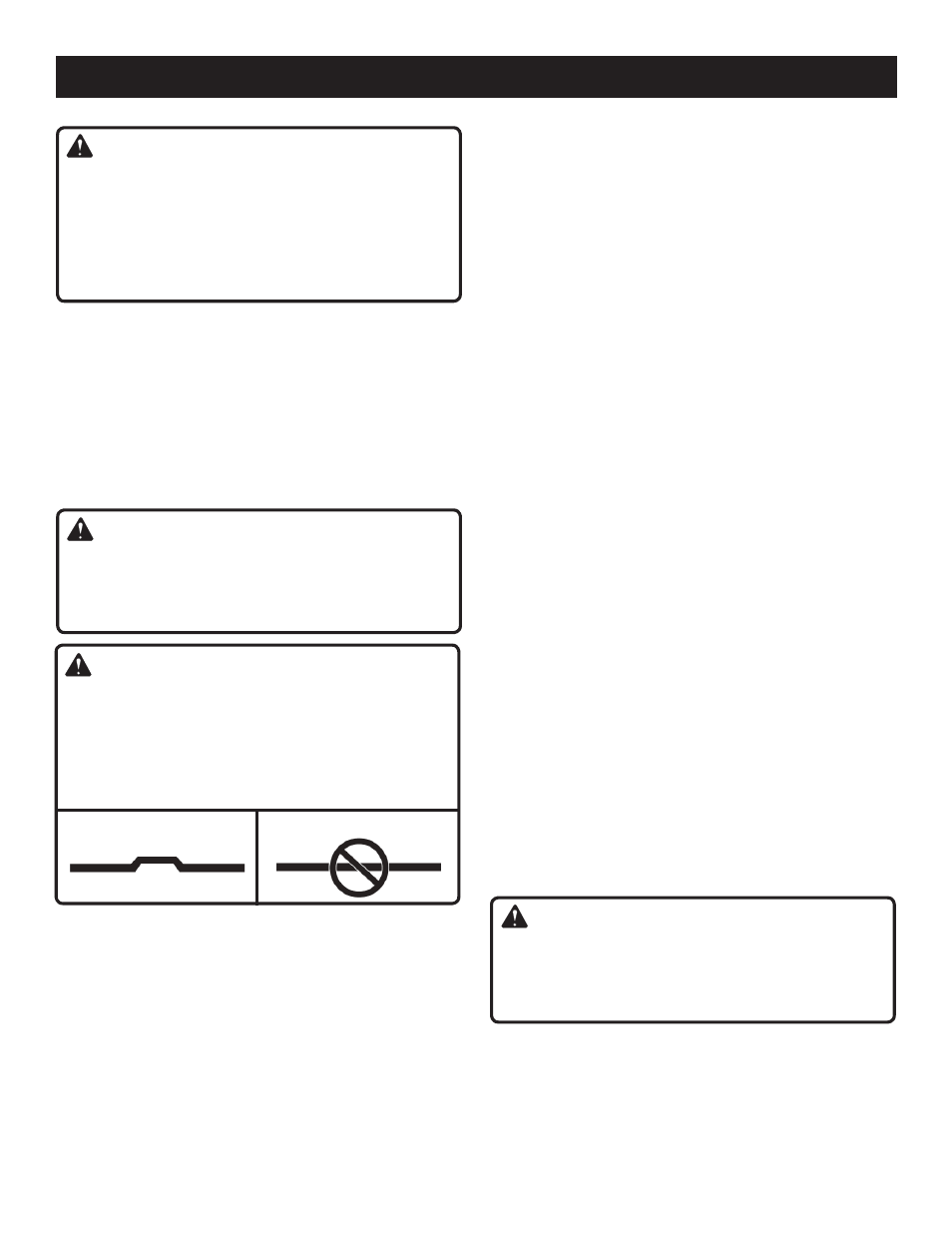

Use ONLY Type 27 depressed center wheels (such

as the one provided with this product). NEVER attach

a Type 1 straight or cut-off wheel to this angle grind-

er. This product is only designed for grinding and

sanding. Use for any other purpose is not recommended

and creates a hazard, which will result in serious injury.

Type 27 − OK TO use

Type 1 − dO nOT use

OPERATION

gRINDINg AND SANDINg

See Figures 4 - 5, page 11.

Always carefully select and use grinding wheels that are

recommended for the material to be ground.

Make sure that the minimum operating speed of any

accessory wheel selected is not less than 11,000 RPM.

The grinding wheel provided with the angle grinder is suit-

able for grinding welds, preparing surfaces to be welded,

grinding structural steel, and grinding stainless steel.

Secure all work before beginning any operation.

The abrasive mop disc is suitable for sanding flat metal

or wood surfaces.

Secure small workpieces in a vise or clamp to a work-

bench.

The key to efficient operation is by controlling the pres-

sure and surface contact between the grinding wheel and

workpiece.

Flat surfaces are ground at an acute angle, normally

between 5

° and 15°.

For maximum control, hold the angle grinder in front and

away from you with both hands, keeping the grinding

wheel clear of the workpiece.

Start the angle grinder and let the motor and grinding

wheel build up to full speed.

Gradually lower angle grinder until the grinding wheel

contacts the workpiece.

For best results keep the angle grinder tilted at an angle

from 5

° and 15° and continuously moving at a steady,

consistent pace.

Move the angle grinder back and forth or up and down

over the work area.

Keep the angle grinder moving so that an excessive

amount of material is not removed from one area.

If the angle grinder is held in one spot too long, it will

gouge and cut grooves in the workpiece.

If the angle grinder is held at too sharp an angle, it will

also gouge the workpiece because of concentration of

pressure on a small area.

Use just enough pressure to keep the angle grinder from

chattering or bouncing. Heavy pressure will decrease its

speed and put a strain on the motor.

Normally the weight of the tool alone is adequate for most

grinding jobs.

Use light pressure when grinding jagged edges or loose

bolts where there is the potential for the angle grinder to

snag on the metal edge.

Lift the angle grinder away from the workpiece before

turning the angle grinder off.

NOTE: Only the grinding wheel is included with this tool.

WARNINg:

Before performing any adjustment, make sure the tool

is unplugged from the power supply and the switch is in

the OFF ( O ) position. Failure to heed this warning could

result in serious personal injury.