Warning – Craftsman 137.21236 User Manual

Page 15

14

15

14

15

5. If the miter angle desired is not one of the

nine positive stops, simply lock the miter

table into position by turning the miter handle

in the clockwise direction.

To Adjust the Indicator:

(1) Adjust the indicator (3) to the 0 ° mark on

the miter scale (4) to position the miter

table.

(2) Release positive stop locking lever (2).

Tighten miter handle.

Fig. K

and then secure by tightening the miter

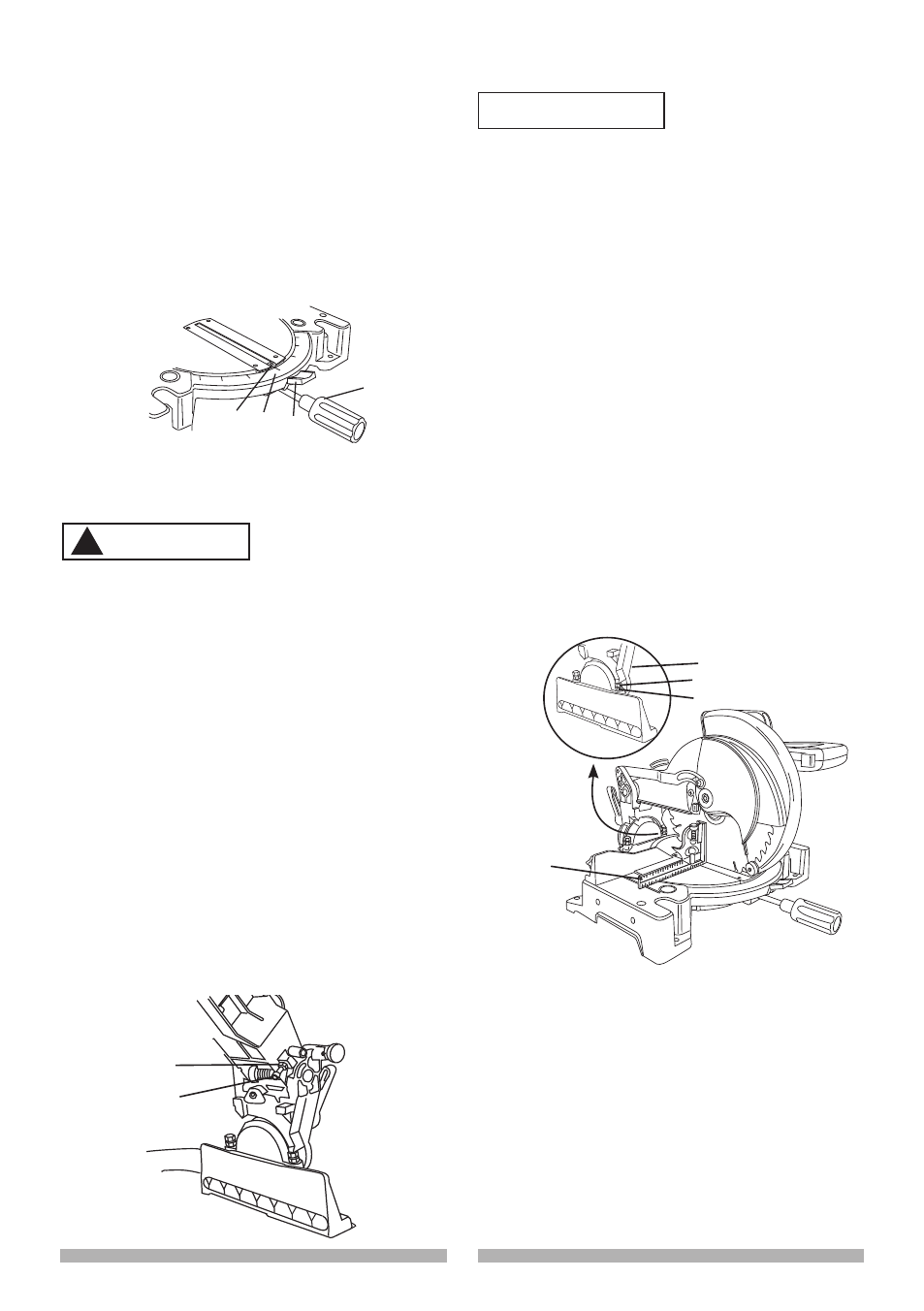

CUTTING ARM TRAVEL

Cutting Arm Downward Travel Adjustment

(Fig. L)

To avoid injury from unexpected starting

or electrical shock, turn the switch OFF

and remove the power cord from the power

source.

NOTE

: Before each cutting operation, check the

position of the blade to make sure it does not

contact any metal surface. If the blade contacts

any metal surface, the depth of travel must be

adjusted.

1. Lower the blade as far as possible.

2. Loosen the locknut (3).

3. Turn the adjustment bolt (4) out

(counterclockwise) to decrease the cutting

depth or in (clockwise) to increase the cutting

depth.

4. Carefully rotate the blade manually to check

for contact. Avoid touching blade points or

edges.

5. Repeat until adjusted properly, and tighten

the locknut to secure the adjustment bolt into

position.

Fig. L

1

2

4

3

3

4

WARNING

!

BEVEL STOP ADJUSTMENT (FIG. M, N, O)

To avoid injury from unexpected starting

or electrical shock, make sure the trigger is

released and remove the power cord from the

power source.

WARNING

!

90° Bevel Adjustment (Fig. M)

1. Loosen bevel lock handle (1) and tilt the

cutting arm completely to the right. Tighten

the bevel lock handle. Lower blade.

2. Place a combination square (2) on the miter

table with the rule against the table and the

heel of the square against the saw blade.

3. If the blade is not 90° square with the miter

table, loosen the bevel lock handle, tilt the

cutting head completely to the left, loosen

the locknut (4) on the bevel angle adjustment

bolt (3) and use a 13 mm wrench to adjust

the bolt (3) in or out to increase or decrease

the bevel angle.

4. Tilt the cutting arm to back to the right at 90°

bevel and recheck for alignment.

5. Repeat steps 1 through 4 if further

adjustment is needed.

6. Tighten bevel lock handle and locknut (4)

when alignment is achieved.

Fig. M

3

2

4

1