Just Better Copper Capillary Tubing User Manual

Copper capillary tubing, Factors affecting refrigerant flow, Application and engineering data

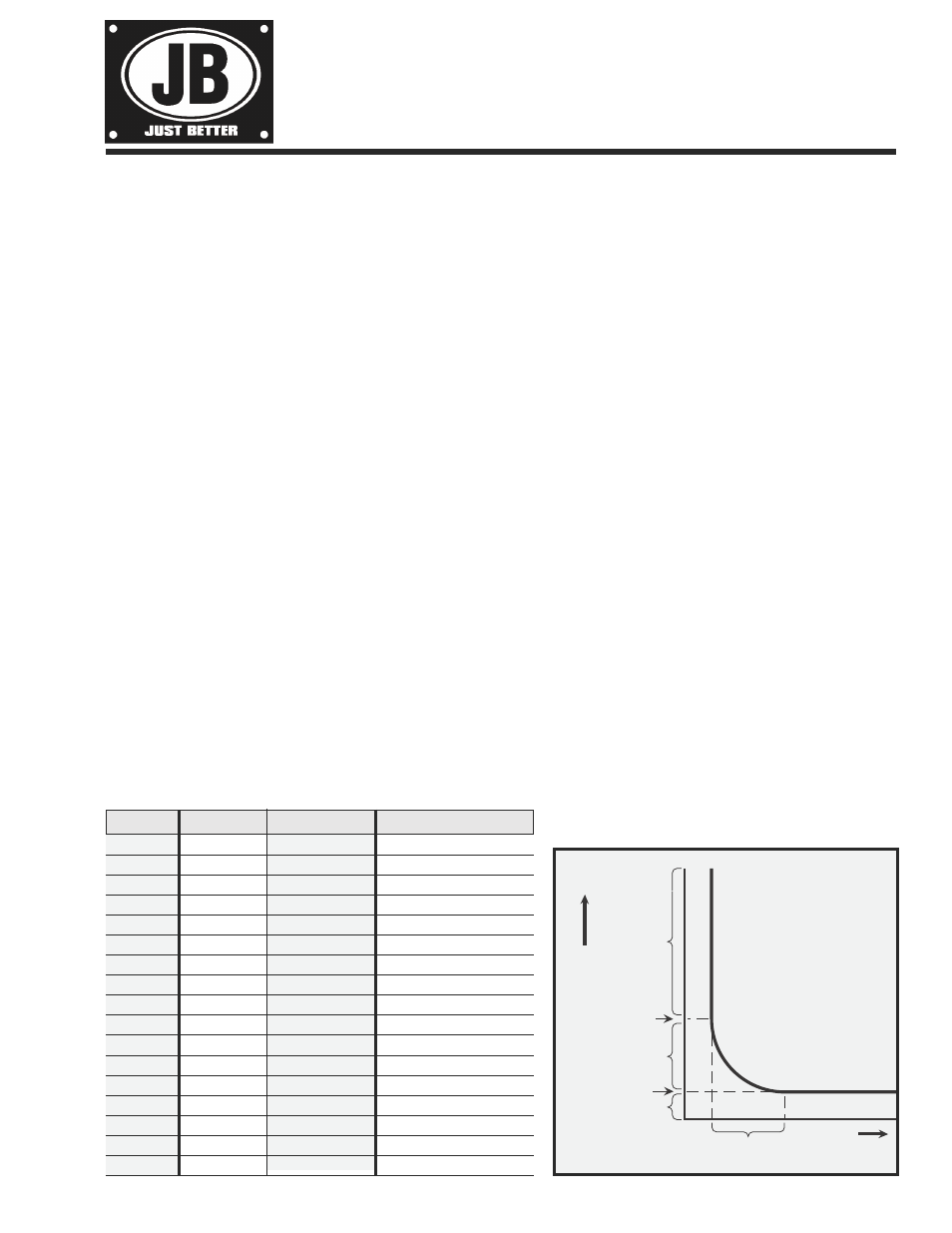

EXTRA

LONG

LENGTHS

CRITICAL

POINT "L"

OPTIMUM

LENGTH RANGE

5 to 16 FT.

SHORT LENGTH

ACTS LIKE ORIFICE

OPTIMUM FLOW

RANGE

FLOW

LENGTH

CRITICAL POINT "S"

Typical flow curve showing

changes in flow of

refrigerant through a

capillary tube with a

change in the length of the

cap tub.

The size of the cap tube is fairly critical.

Unlike orifices, such as expansion valve seats,

capillary tubes depend on their length as well as

their diameter to determine their total restriction.

The relationship between these two factors are

shown in the following charts. A change in

diameter on a percentage basis can change the

flow more than an equal change in length. To

illustrate, changing the diameter by .005" as

between .026" I.D. and .031" I.D. can double

the flow.

Restriction can also be changed by length-

ening or shortening the cap tub. The longer the

tube, the slower the flow; the shorter the tube, the

faster the flow. The general flow curve graph

(right) shows what happens to the flow of

refrigerant through a cap tube as the length is

changed. This curve is not meant to give specific

flows but to simply illustrate what happens with

all cap tubes so that the general flow pattern can

be understood.

By following the flow curve from left to right it

can be seen that for the very longest length the

flow is the smallest. Then as the cap tube length

is decreased, the flow increases slowly until

critical point "L" is reached.

At this point the flow increases more rapidly

with each reduction in length until critical point "S"

is reached. From this point on, further decrease in

DIAMETER AND LENGTH

FACTORS AFFECTING REFRIGERANT FLOW

APPLICATION AND ENGINEERING DATA

Copper Capillary Tubing

For Refrigeration and Air-Conditioning

SHORT COIL

100 FT. COILS

10 COILS

DESCRIPTION

TC-26-16

TC-26-100

TC-26-100-101

.026 ID x .072 OD x 16'

TC-31-12

TC-31-100

TC-31-100-101

.031 ID x .083 OD x 12'

TC-36-12

TC-36-100

TC-36-100-101

.036 ID x .087 OD x 12'

TC-42-12

TC-42-100

TC-42-100-101

.042 ID x .093 OD x 12'

TC-44-12

TC-44-100

TC-44-100-101

.044 ID x .109 OD x 12'

TC-49-11

TC-49-100

TC-49-100-101

.049 ID x .099 OD x 11'

TC-50-11

TC-50-100

TC-50-100-101

.050 ID x .114 OD x 11'

TC-54-11

TC-54-100

TC-54-100-101

.054 ID x .106 OD x 11'

TC-55-11

TC-55-100

TC-55-100-101

.055 ID x .125 OD x 11'

TC-59-10

TC-59-100

TC-59-100-101

.059 ID x .112 OD x 10'

TC-64-10

TC-64-100

TC-64-100-101

.064 ID x .125 OD x 10'

TC-70-12

TC-70-100

TC-70-100-101

.070 ID x .125 OD x 12'

TC-75-9

TC-75-100

TC-75-100-101

.075 ID x .125 OD x 9'

TC-80-10

TC-80-100

TC-80-100-101

.080 ID x .145 OD x 10'

TC-85-9

TC-85-100

TC-85-100-101

.085 ID x .145 OD x 9'

TC-90-7

TC-90-100

TC-90-100-101

.090 ID x .145 OD x 7'

TC-100-10

TC-100-100

TC-100-100-101

.100 ID x .156 OD x 10'

length causes ever increasing flow. From the

study of this typical curve, certain pertinent

conclusions can be reached that directly affect

the field application of capillary tubes.

On the graph, the section above the critical

point "L" is marked as extra long lengths.

Attempting to increase restriction (i.e. reduce

flow) by increasing length into this region is not

only uneconomical but frequently hopeless. In

addition, tubes in this range may not be respon-

sive enough to changes in head pressures during

operation. All in all, tube lengths in this range

should be avoided where possible.

Continuing down the graph, the section

below critical point "S" should be avoided like the

plague. In this range, the tube is so short that

even small changes in length will cause very

large increases in flow. This is caused by the fact

that the length no longer affects the flow and the

tube now beings to act more like an orifice than a

capillary tube. But, without the other components

necessary to control an orifice, such as are

present in an expansion valve or high side float, a

very short cap tube will give wildly erratic opera-

tion under varying ambients and loads.

All of this would be meaningless without

some definite way to use this information. Al-

though the critical points will vary depending on

the I.D. of the cap tubing being used, a very safe

operating rule-of-thumb can be offered. Keep the

cap tube no shorter than 5 ft. and no longer

than 16 ft.

© COPYRIGHT 2007 J/B INDUSTRIES INC.