Evolution gx engine simple start ignition system, Installation of the gx simple start ignition unit, Enabling or disabling battery test – Evolution Engines EVOE50GX User Manual

Page 3: Enabling or disabling battery test, continued

5

6

Evolution GX Engine Simple Start Ignition System

The spark ignition included with your Evolution gas engine is a modern generation electronic ignition. There are many useful functions built

into the microprocessor of this unit.

In addition to the basic ignition functions, the unit has a FAIL-SAFE feature. After 90 seconds of inactivity it automatically switches to an

inactive state. In order to restart normal operation, it is necessary to turn the battery switch off and then back on. This function preserves

battery life should the switch be left in the ON position during inactivity.

Installation of the GX Simple Start Ignition Unit

While installing the ignition unit in your model, be careful to have all parts connected to the unit and the engine situated as far as practical

from the radio receiver and radio antenna. Secure the ignition unit to the airframe using the provided hardware. Install the bolts through

the three rubber grommets and tighten securely. The grommets help to dampen the ignition unit from vibration. DO NOT HARD MOUNT. The

throttle servo should be mounted a distance of 8–12 inches from the engine. The spark plug cable must not touch any part of the model

structure as vibration may damage the cable. If this is not practical, it will be necessary to provide an insulation material for the cable. All

components must be protected from contact with engine fuel.

DESCrIPTION

The ICU-L ignition makes the selection of a pre-ignition

curve (“short” or “long” exhaust stroke) possible. You

can change the setting using the supplied programming

connector.

The setting is permanently stored in the memory of the

ignition even if the supply voltage is turned off. You

do not need to change the setting when you turn the

ignition on again.

BASIC FEATUrES

-Two preprogrammed pre-ignition curves (“short,” which

is the default setting, and “long,” for tuned silencer)

-Sleep mode after 90 seconds of engine inactivity to

save battery power

-Ignition shuts off if the engine runs counterclockwise

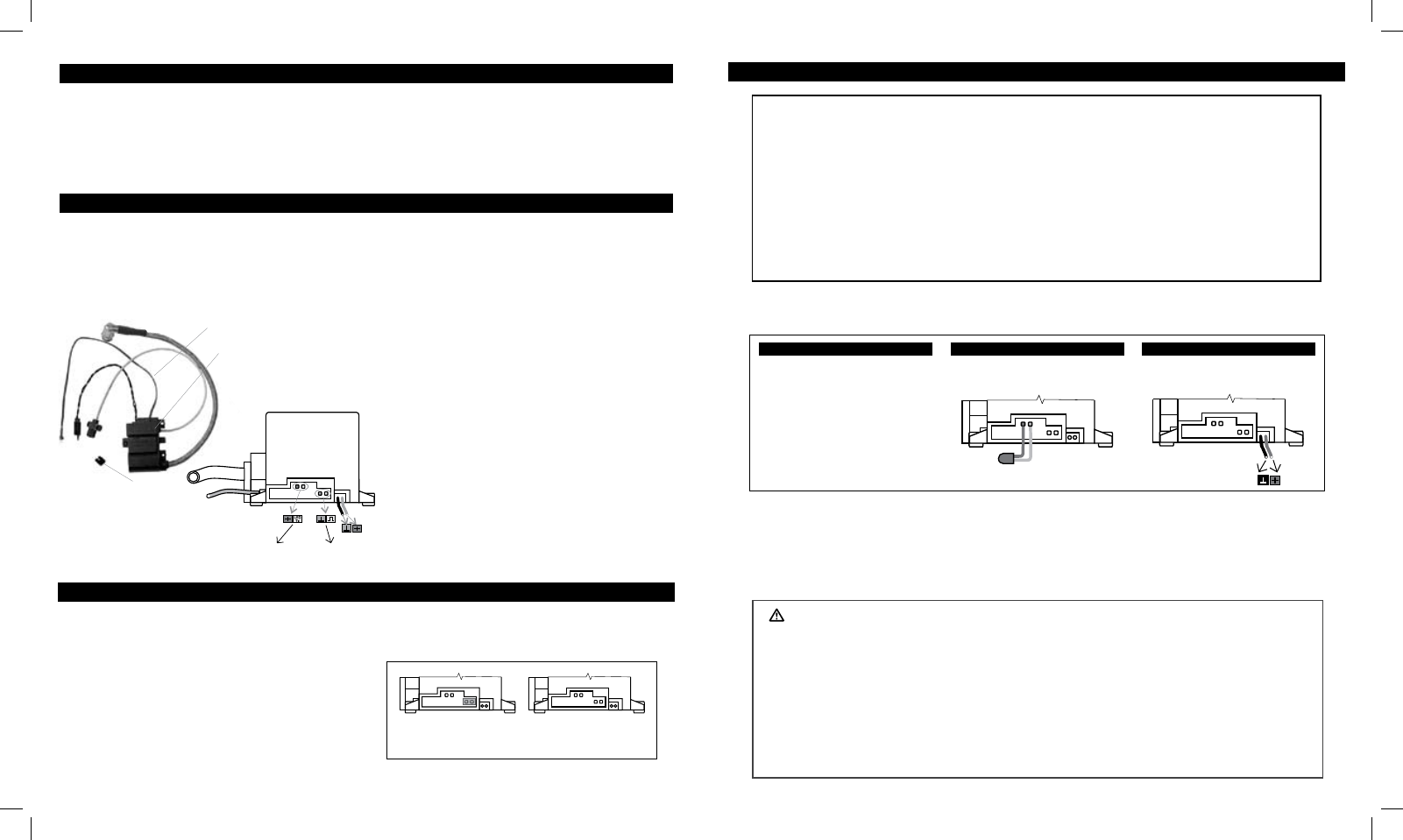

Programming

Connector

LED

Ignition

LED

PROGRAMMING

programming connector

POWER

power connector

Package Contents

-ignition

-LED

-programming connector

-manual

Enabling or Disabling Battery Test

This ignition makes it possible to enable or disable the battery test. The battery test is very useful when Li-Po or Li-Ion batteries are used.

During the test, a series of flashes are generated and voltage is measured. When the battery passes the test, that means it will run for a

minimum of 10 minutes in flight.

BATTERY TEST ENABLED:

- close programming pins with

enclosed jumper

BATTERY TEST DISABLED:

- open programming pins

(remove jumper)

- Battery test is disabled when jumper is removed and programming

pins are open (this is the default condition of the engine as

shipped from Evolution)

- Battery test is enabled when jumper is plugged and programming

pins are closed

- Enable or disable battery test when the ignition is off

Enabling or Disabling Battery Test, Continued

If you want to change the type of silencer, do the first two steps and then continue to PROGRAMMING SEQUENCE.

Otherwise, follow these steps:

Starting Sequence

- Move propeller to put the piston at bottom dead center of its travel

- Keep your hands outside of the propeller radius to avoid serious

injury

- Hold the airplane and switch on ignition

- If battery test is enabled, the ignition starts battery test; during

this test, a series of sparks are generated for about 2 seconds

and LED is blinking

- If battery test is disabled, then LED blinks for about 2 seconds

- If LED turns off, you can fly; otherwise battery is low

FIrST STEP

- Screw on pickup on engine

- Attach the plastic protection to the high-voltage

cable

- Connect boot to plug

- Mount ground terminal on the high-voltage cable

bolt holding the engine to the motor mount

- Mount the ignition to the airplane

SECOND STEP

- Connect enclosed LED to the ignition (red or red/

black wire to left)

STArT

- Keep clear of the propeller

- Connect battery with the ignition box

WArNING Use the ignition only in dry conditions

Use recommended number and type of cells for every ignition type

The product is specified for RC engines only (other use must be approved by the manufacturer)

Do not take off the plug cap if the ignition is on

Danger of electric injury (voltage over 20,000V)

Recharge ignition battery only outside the model

Because of possible interferences, ignition and battery should be placed at least 25 cm from the receiver

The manufacturer is not responsible for damages caused by not following the manual or by using the ignition for anything

other than RC engines. Guarantee is void if the high-voltage (HV) cable or HV isolation is damaged, the pickup or batteries

are reversed, or the ignition box is opened.

Ignition System Warning

When using the GX electronic ignition, it is designed to fire the spark

plug for 1 second to check the condition of the battery prior to start-

ing the engine. If the engine is in the compression position (i.e., the

piston is above the exhaust port in either the up OR down part of the

stroke), any compressed fumes may ignite, causing the propeller to

turn and possibly the engine to start unintentionally.

To prevent injury with the Evolution Gasoline GX Ignition System, the

Ignition Power Switch must be turned off first; then check to see that

the piston is in the Bottom Dead Center (BDC) position. (Bottom Dead

Center can be found by rotating the propeller through the compression

stroke. As you rotate the propeller you will feel it tighten, then suddenly

loosen. Once the turn becomes very easy, you have completed the

compression stroke and are at BDC.) Once you are sure the piston is

in this position, you may turn on the ignition power switch and operate

the system safely.

As always, it is important to use extreme care when near or with

engines, fuel and propellers. Please use caution when working with

these components. If you have any questions or concerns, please con-

tact the Horizon Support Team at 1-877-504-0233 or productsupport@

horizonhobby.com.