Warning, Caution - ratchet head – CDI Torque PRE-SET TORQUE WRENCH User Manual

Page 2

sAFETY MEssAGEs

WARNING

Read operation manual completely

before using torque instrument and

store for future reference.

Wear safety goggles-both user and

bystanders

• An out of calibration torque wrench

can cause part or tool breakage

• Periodic re-calibration is necessary to

maintain accuracy

• Do not exceed rated torque as

overtorquing can cause wrench or part

failure

• Do not use torque instrument to break

fasteners loose

• Do not use cheater extension on the

handle to apply torque

• Broken or slipping tools can cause

injury.

CAUTION

- RATCHET HEAD

Ratchet mechanism may slip or break

if dirty, mismatched or worn parts are

used, or direction lever is not fully

engaged. Ratchets that slip or break

can cause injury.

MAINTENANCE / sERvICE

1. The torque wrench’s internal mechanism is

permanently lubricated during assembly.

Do not

attempt to lubricate the internal mechanism.

2. Clean torque wrench by wiping.

Do not immerse.

3. Store torque wrench in protective tube at its lowest

torque setting.

Do not force handle below lowest

setting.

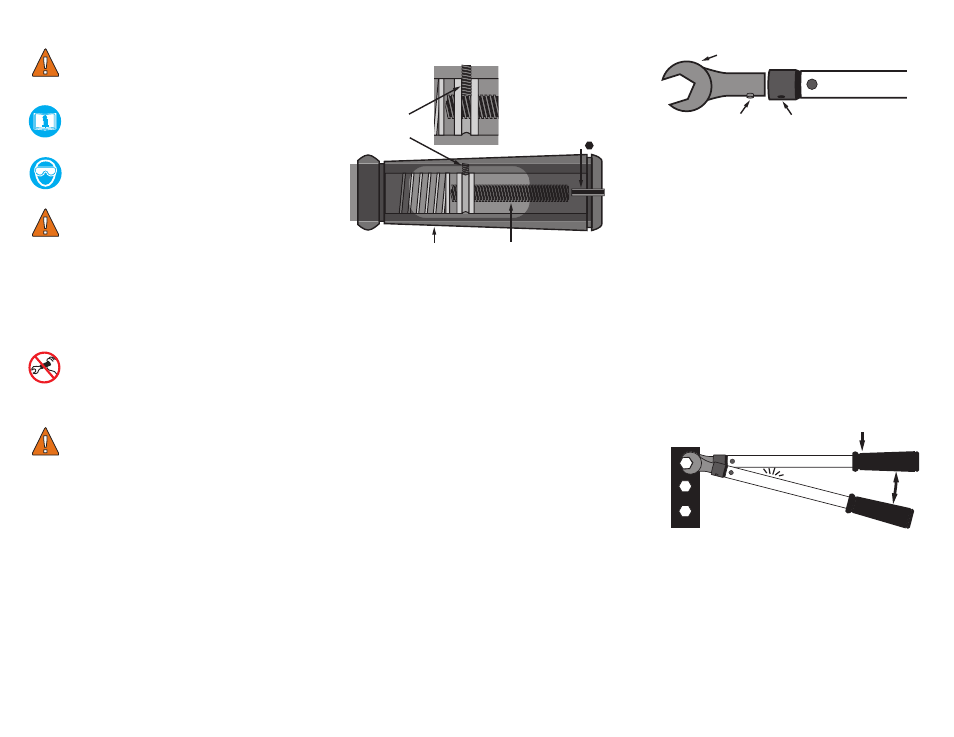

ADJUsTMENTs OF

TORQUE sETTINGs

1. To set the torque values, loosen locking set screw

(A) with a 3/32” hex wrench.

2. Insert interchangeable plain drive head (D) (consult

factory for model number) into receptacle (F)

until the locking pin (E) is fully engaged with the

corresponding receptacle hole. (See Figure I)

3. Place a T- handle hex wrench through adjusting hex

opening (C) at rear of handle grip until engaging the

adjusting screw (B).

4. Place the wrench on a torque tester. Turn adjusting

screw (B) with the T- handle hex wrench clockwise

to increase torque and counter-clockwise to

decrease torque.

5. To set torque, apply a slow steady force on the

pre-set wrench. Turn adjusting screw (B) until the

desired torque setting is displayed on the torque

tester.

6. Tighten the locking set screw to 10 in, lbs. (A). To

ensure that wrench setting is repeatable, cycle

three more times. If the readings are not as desired,

repeat steps 1-5.

NOTE:

• Some interchangeable heads used in pre-set torque

wrenches have lengths that vary.

• It is recommended that the pre-set torque wrenches

are to be calibrated with the interchangeable head

that is to be used to assure the greatest accuracy in

calibration.

• Hex wrenches used to adjust torque settings will

vary in length.

To verify calibration or to torque a fastener, keep hand

centered on the handle grip. Apply a slow force until

a click/impulse is heard or felt. Stop and allow the

wrench to reset.

Figure I

sETTING TORQUE

LOCKING SET

SCREW (A)

HANDLE

GRIP

ADJUSTING

SCREW (B)

ADJUSTING HEX

OPENING (C)

INTERCHANGEABLE

HEAD (D)

LOCKING

PIN (E)

RECEPTACLE (F)

APPLY FORCE

RELEASE

FORCE TO RESET

CLICK