Warning, Caution - ratchet head – CDI Torque MICRO-ADJUSTABLE TORQUE SCREWDRIVER User Manual

Page 2

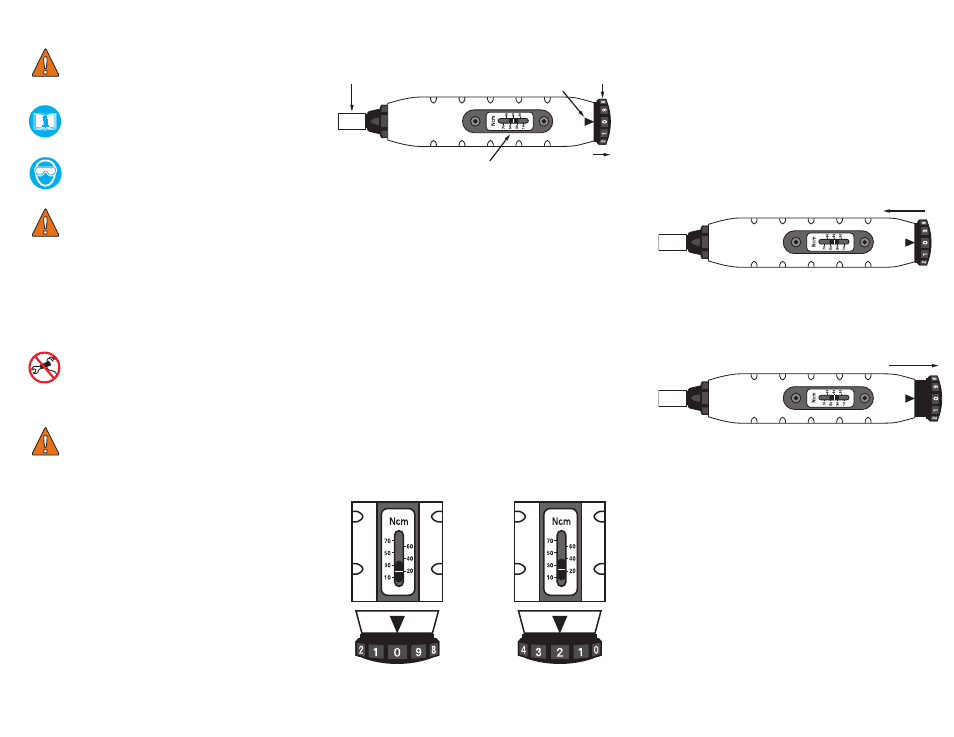

A. To unlock adjusting knob hold body of screwdriver

and firmly pull knob to rear. (See Figure IV)

B. Set screwdriver to desired torque as follows:

EXAMPLE -22 Ncm.

1. Turn adjusting knob clockwise until the major

graduation line is aligned with the

20 on scale

(See Figure I) and arrow indicator on screwdriver

body is in line to “0” graduation on the adjusting

knob.

2. Turn adjusting knob two increments clockwise.

Screwdriver is now set at

22 Ncm. (See Figure II)

3. To lock adjusting knob, push towards the drive until

it clicks into the lock position. (See Figure III)

4. To torque fastener, keep hand centered on the

screwdriver grip.Turn screwdriver clockwise until a

click/impulse is heard or felt. The screwdriver will

automatically reset for the next operation.

Figure I

Figure II

ADJUSTING KNOB LOCKED POSITION

Figure III

ADJUSTING KNOB UNLOCKED POSITION

Figure IV

sAFETY MEssAGEs

WARNING

Read operation manual completely

before using torque instrument and

store for future reference.

Wear safety goggles-both user and

bystanders

• An out of calibration torque screwdriver

can cause part or tool breakage

• Periodic re-calibration is necessary to

maintain accuracy

• Do not exceed rated torque as

overtorquing can cause screwdriver or

part failure

• Do not use torque instrument to break

fasteners loose

• Do not use cheater extension on the

handle to apply torque

• Broken or slipping tools can cause

injury.

CAUTION

- RATCHET HEAD

Ratchet mechanism may slip or break

if dirty, mismatched or worn parts are

used, or direction lever is not fully

engaged. Ratchets that slip or break

can cause injury.

MAINTENANCE / sERvICE

1. The torque screwdriver’s internal mechanism is

permanently lubricated during assembly.

Do not

attempt to lubricate the internal mechanism.

2. Clean torque screwdriver’s by wiping.

Do not

immerse.

3. Store torque screwdriver’s in protective tube at its

lowest torque setting.

Do not force handle below

lowest setting.

ADJUsTMENTs OF

TORqUE sETTINGs

1/4” FEMALE

HEX DRIVE

MAJOR

GRADUATIONS

ADJUSTING KNOB

PULL TO UNLOCK

SET TORQUE VALUE

MINOR

GRADUATIONS

ARROW

INDICATOR