Follower needle dial, Electric signal dial, Setting electric contact arm on dual scale model – CDI Torque DIAL TORQUE WRENCH DUAL SCALE User Manual

Page 3

Before using all models of dial torque wrenches, it is

strongly suggested to cycle/operate them 3 times at

full scale in the torque direction in which they will be

used. Dial torque wrenches must always be

zeroed

before use. To set orange pusher & blue follower

needle for right-hand (CW) torquing:

1. Turn bezel in left-hand (CCW) direction until, blue

memory follower needle contacts orange pusher

needle.

2. Continue to turn bezel left-hand (CCW) until blue

memory follower needle is lined up with

zero (0) of

outer graduation on portion of dial for IN.LB., FT.LB.,

METRIC readings.

3. Apply force on the wrench handle until blue follower

needle reaches desired torque. When force is released

orange pusher needle will return to

zero and blue

memory follower needle will remain at torque applied.

4. For repetitive torque operations (once the

zero

has been set as instructed above), the blue memory

follower needle can be returned to

zero by use of the

follower needle knob. It is ready for the next operation.

5.

IMPORTANT - When using the memory feature

always make sure that the blue follower memory

needle is on

zero before torquing.

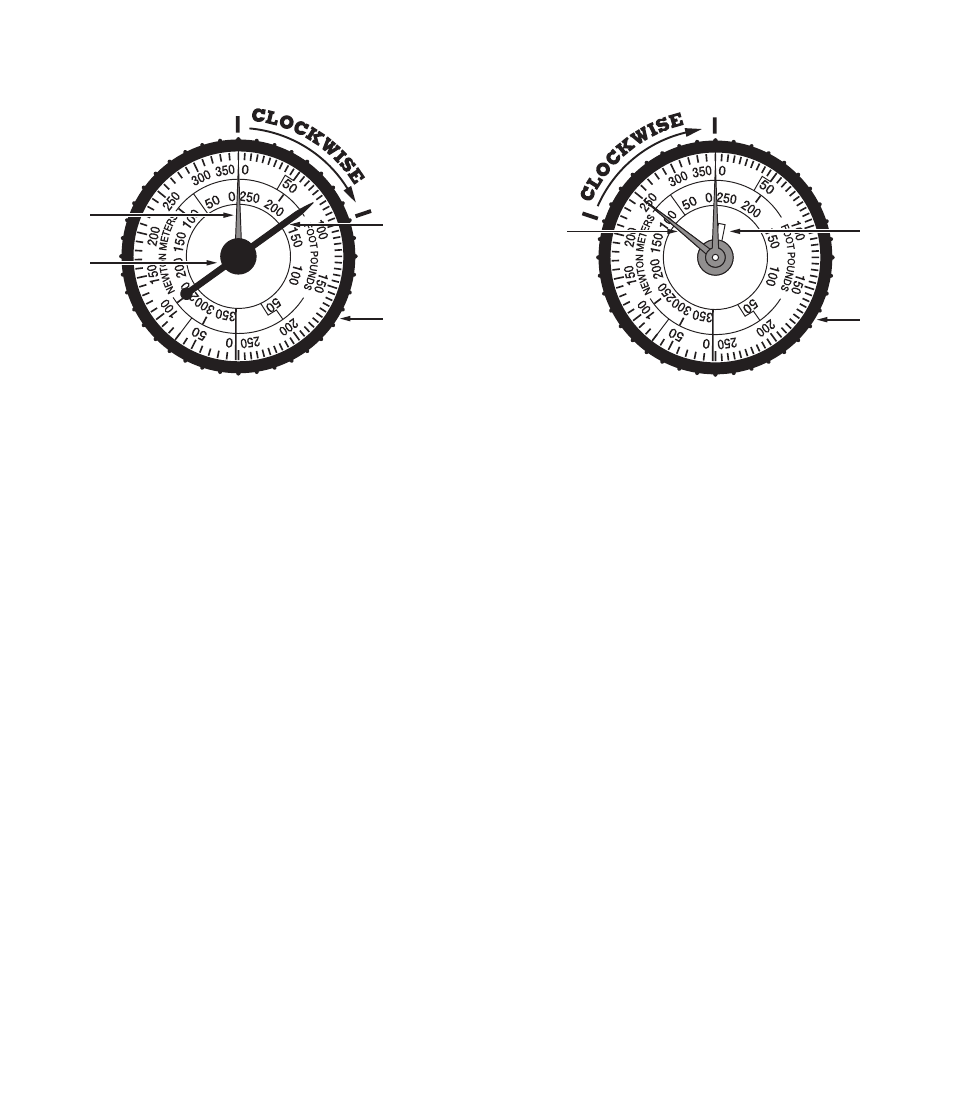

BEZEL

MEMORY

FOLLOWER

NEEDLE

(BLUE)

PUSHER

NEEDLE

(ORANGE)

FOLLOWER NEEdLE dIAL

MEMORY

FOLLOWER

NEEDLE

KNOB

SETTING MEMORY

FOLLOWER NEEdLE

ON dUAL SCALE MOdEL

BEZEL

ELECTRIC

CONTACT

ARM

PUSHER

NEEDLE

(ORANGE)

ELECTRIC SIGNAL dIAL

Setting electric arm at

zero with all torque readings

made from inner circle of numbers on the scale for

right-hand (CW) torquing, and the outer circle of

numbers on the scale for left-hand (CCW) torquing:

1. Turn bezel (CCW) until light and buzzer goes on.

2. Continue to turn bezel (CCW) until inner

zero of

desired scale (English or Metric) is lined up with

orange pusher needle.

3. Now turn bezel (CW) until light goes off and

orange pusher needle is aligned with desired torque

graduation in inner portion of scale orange pusher

needle is now preset to desired torque value.

4. Apply force to handle in the (CW) direction. When

the preset torque value is reached the light and

buzzer will go on. When force on the handle is

released orange pusher needle will return to the

preset torque value.

5. To change the preset torque value to another,

turn the bezel as required to the new torque value

within the same dial graduation and proceed as in

step 4 above.

6.

IMPORTANT - Always make sure that the electric

contact arm is

zeroed.

SETTING ELECTRIC

CONTACT ARM

ON dUAL SCALE MOdEL