Operator instruction, Use of adapters, extensions and universals – CDI Torque HEAVY-DUTY TORQUE AND ANGLE Electronic Torque Wrench User Manual

Page 4

OPERATOR INSTRUcTION

1. Turn the wrench

ON by momentarily pushing the

ON/OFF key. The display will return to the mode of

operation and preset values previously set up.

2. To change the mode of operation,

TORQUE or

ANGLE, scroll the selections by momentarily

pushing the

UNITS key. The preset values for each

mode will be displayed.

3. Use the

UP and DOWN keys to change the preset

values.

(Note:

TORQUE is also measured in ANGLE mode).

4. Grasp the center of the handle and slowly apply

torque to the fastener until the

Green LED or audible

buzzer alerts you to stop.

5. Release torque. Note the

PEAK reading flashing on

the display for 10 seconds, unless torque is re-

applied or the

ON/OFF key is pushed to clear the

display.

6. In

ANGLE mode, place the wrench on a flat surface

during

ZEROTARE.

7. The

BAR GRAPH shows measured TORQUE or ANGLE

as a percentage (10-100%) of Preset.

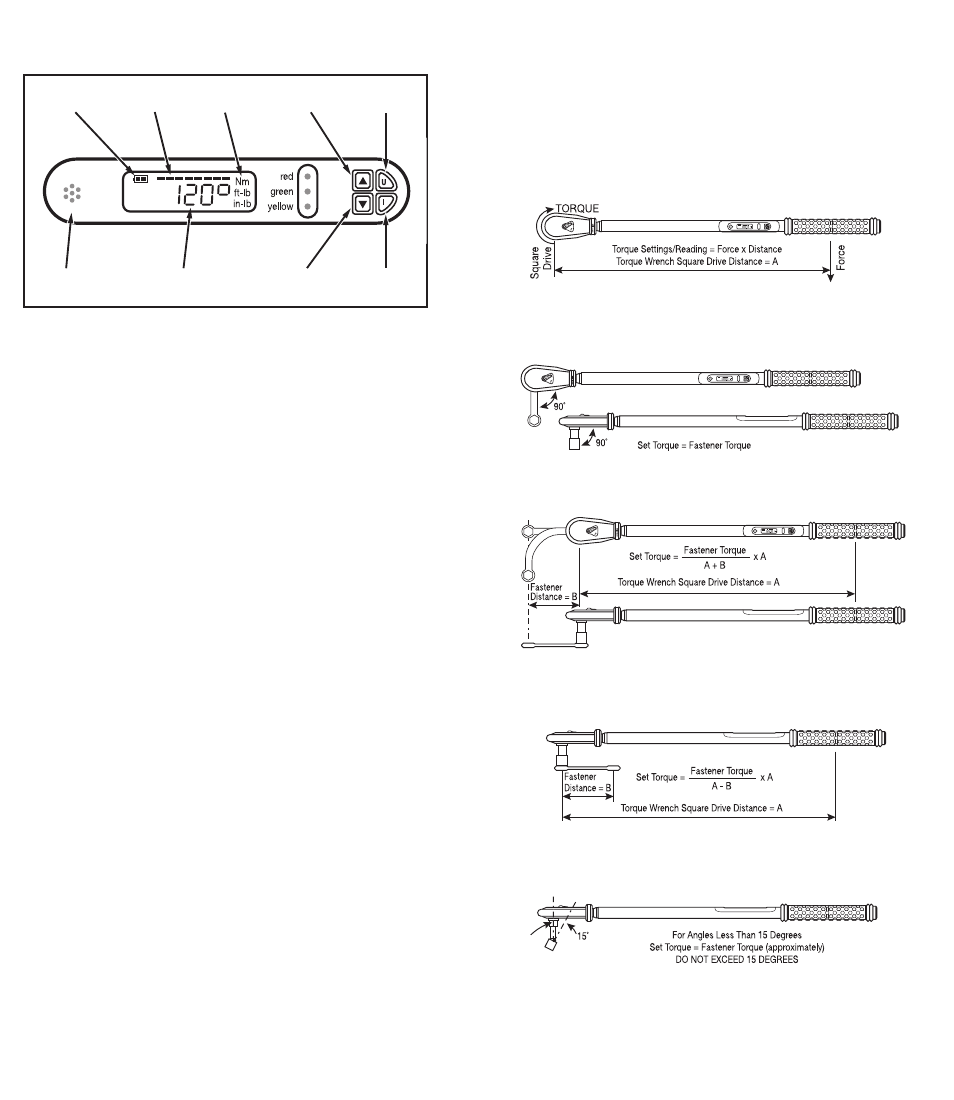

USE OF ADAPTERS,

ExTENSIONS AND UNIVERSALS

Anytime an adapter, extension or universal is used

with a torque wrench in such a way that the fastener

distance is different that the torque wrench square

drive distance, an adjustment to the set torque is

required to get proper fastener torque.

Fastener torque equals torque wrench square drive

torque. Wrench setting is equal to desired fastener

torque.

Fastener torque equals torque wrench square drive

torque. Wrench setting is equal to desired fastener

torque.

Fastener torque is greater than torque wrench square

drive torque. Calculated setting will be lower than

desired fastener torque.

Fastener torque is less than torque wrench square drive

torque. Calculated setting will be higher than desired

fastener torque.

When using a universal or wobble extension, do

not exceed more than 15 degrees of offset from

perpendicular drive.

100%

30%

5%

REPLACE BATTERY

BATTERY

CONDITION

AUDIBLE

ALERT

TORQUE AND/OR

ANGLE DISPLAY

DECREMENT

KEY

ON/OFF

KEY

BAR

GRAPH

TORQUE

UNITS

INCREMENT

KEY

UNIT

KEY

TORQUE

Squar

e

Driv

e

For

ce

Torque Settings/Reading = Force x Distance

Torque Wrench Square Drive Distance = A

Set Torque = Fastener Torque

Set Torque =

x A

Fastener Torque

Torque Wrench Square Drive Distance = A

Fastener

Distance = B

A + B

90˚

90˚

Fastener

Distance = B

Set Torque =

x A

Fastener Torque

Torque Wrench Square Drive Distance = A

For Angles Less Than 15 Degrees

Set Torque = Fastener Torque (approximately)

DO NOT EXCEED 15 DEGREES

A + B

15˚

15˚

Install four fresh “AA” alkaline cells into the handle of the wrench.