Installation (cont’d.), Wiring – Chromalox PQ404-6 User Manual

Page 3

3

INSTALLATION (cont’d.)

SPECIAL INSTRUCTIONS FOR CUSTOMERS SUPPLYING

THEIR OWN CONDENSATE OR PUMP SYSTEMS.

1. Check the voltage of the motor before making the wiring connec-

tion. Some Chromalox boilers are supplied with dual voltage sys-

tems. The motor should always match the voltage of the control

circuit.

2. The motor circuit should be wired into the pump control as shown

in wiring diagram.

3. A heavy-duty vacuum breaker is required when condensate system

is used. (part number ES-89369)

WIRING

1. Wiring to boiler should be as per appropriate wiring diagram sup-

plied with boiler and in accordance with Local and National

Electrical Codes.

2. SAFETY SWITCHES - Purchaser should use a safety switch

between his main power source and the boiler. The safety switch

should use circuit breakers or fuses and be in accordance with

NEC and local codes.

Serious thought should be given to the advisability of using a shunt

trip safety switch of the circuit breaker type as an additional safe-

ty precaution. It is possible to utilize the spare contacts in the low

water cutoff to energize the shunt mechanism on the safety switch.

This is an additional safety feature that prevents a dangerous situ-

ation should a contactor or relay stick. Activation of the shunt trip

device will completely disconnect the boiler from the power sup-

ply. (See Figure 7).

3. Since boiler heating elements are susceptible to lightning damage,

plants not having lightning arresters that have above-ground elec-

trical cable supply sources should install lightning arresters in the

proper size to meet the boiler kw load.

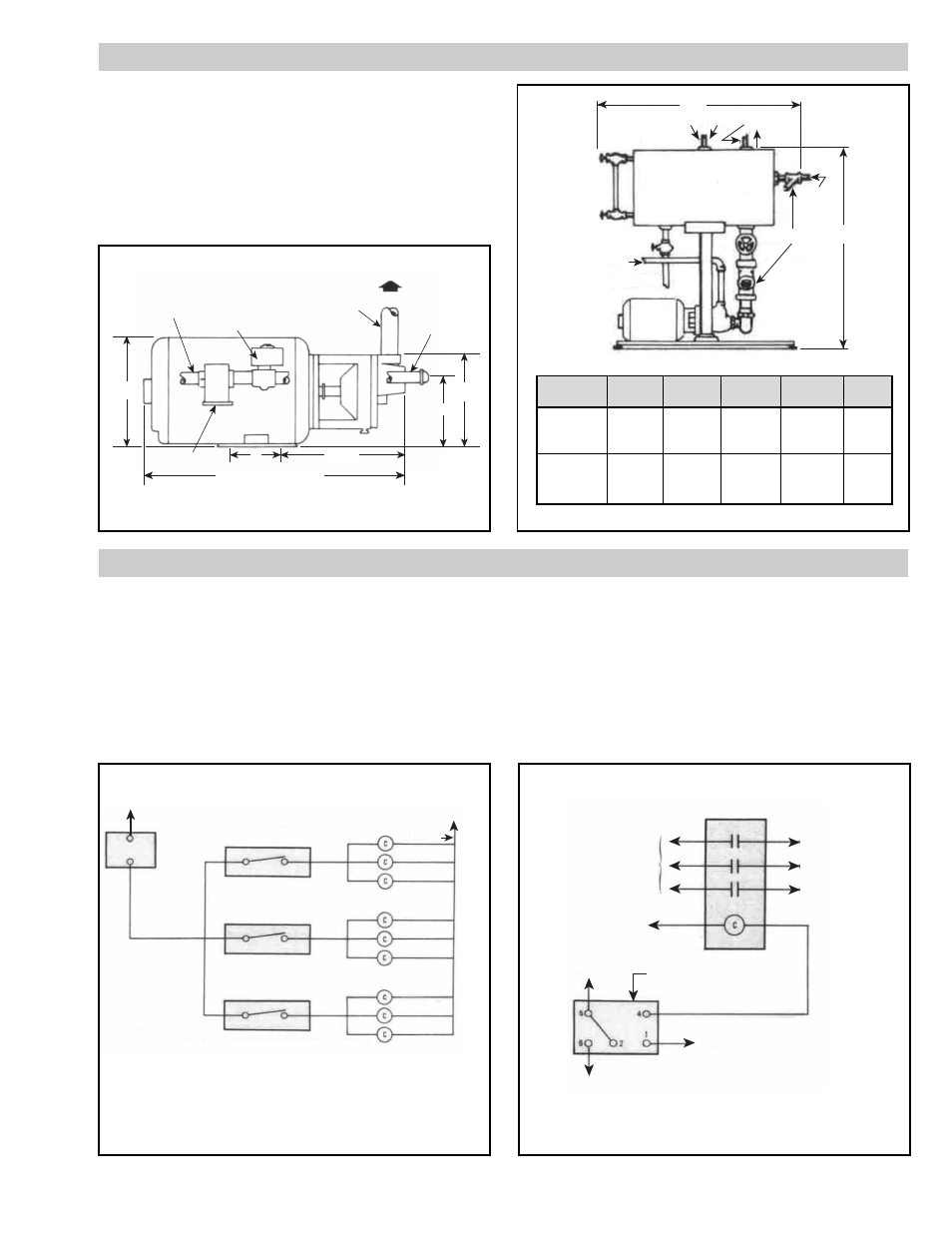

1/2” Water Line

1/2” Solenoid

6-5/8”

1/2” Strainer

3”

7-1/4”

15-1/4” for CHS-150

16-3/8” for CHS-180 to 300

1” Discharge to Boiler

4-1/4”

5-7/8”

Width – 6-1/2

Figure 4 – Motor and Pump Assembly

To Aux.

L.W. C.O.

Hi-Limit

Pressuretrol

Operating

Pressuretrols

To L2 on

Terminal Strip

Common

*Standard on CHS-150 to CHS-300 units in lieu of step

sequencer and operating pressuretrol shown in Figure 8

Figure 6 – Pressuretrol Control System*

Shunt Trip Device

(Supplied by Others)

Supply

Voltage

To Field

Wiring

Input

Terminal

To

L2

To Main

Switch

To Motor Starter

L.W.C.O. &

Pump Control

To Aux.

L.W.C.O.

Figure 7 – Safety Switch (Field Installed)

“W” Dimension – Overall Width

Strainers

H

1/2”

Water

Line

L

1” Outlet

to Boiler

Motor and

Pump

1” Drain

1” Vent

1” Condensate

Return

Figure 5 – Condensate Return System

Model

Max.

Tank Cap.

Number

PSI

(Gal.)

L

H

W

CHS-150

thru

125

33

33-1/4

41-1/2

21

CHS-300

CHS-360

thru

150

40

40

41-1/2

21

CHS-420