Cleaning, maintenance, and lubrication – Chicago Electric 7-1/4" Circular Metal Cut Saw 8897 User Manual

Page 10

Page 10

For technical questions, please call 1-800-444-3353.

SKU 08897

Maintenance and Servicing

Procedures not specifically explained

in this manual must be performed

only by a qualified technician.

TO PREVENT SERIOUS INJURY FROM

ACCIDENTAL OPERATION:

Turn the Power Switch of the tool off and unplug the

tool from its electrical outlet before performing any

inspection, maintenance, or cleaning procedures.

TO PREVENT SERIOUS INJURY

FROM TOOL FAILURE:

Do not use damaged equipment. If abnormal

noise or vibration occurs, have the

problem corrected before further use.

Cleaning, Maintenance,

and Lubrication

1.

BEFORE EACH USE, inspect the general condition

of the tool. Check for loose hardware, misalignment

or binding of moving parts, cracked or broken

parts, damaged electrical wiring, and any other

condition that may affect its safe operation.

2.

Daily: The Saw Blade must be sharp and clean

to perform properly. Depending on materials cut

and frequency of tool use, the Saw Blade may

become clogged with metal particles and dull.

Dull Saw Blades rub the workpiece rather than

cut, which results in increased friction, higher

temperatures, and a burned workpiece. As often

as possible, check the condition of the Saw Blade

and, if necessary, replace a worn Saw Blade with

a new, 7-1/4” diameter, metal cutting Saw Blade

rated at 5,800 RPM or above. See “To Install A

Saw Blade” section for further information.

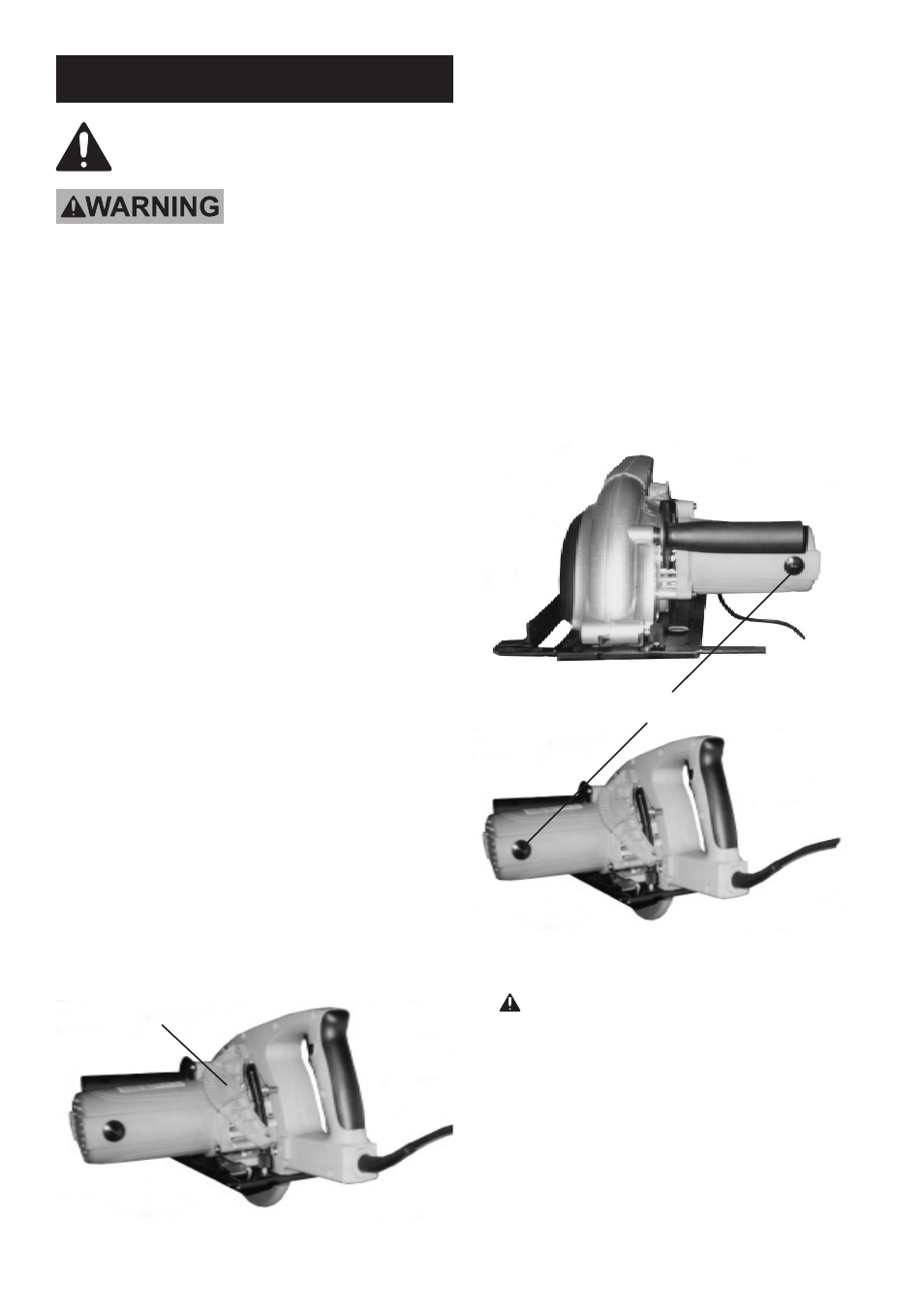

3. With a vacuum or compressed air, remove all metal

debris from the metal debris compartment of the

Saw. To do so, lift up and open the Main Lock Plate

to expose the metal debris compartment. Once

cleaned, close and lower the Main Lock Plate.

Do

not immerse the Saw in liquid. See Figure I, below.

4.

Periodically: The Saw features two Carbon Brushes

which, periodically, should be examined for wear.

The Carbon Brushes are located on each side of the

Motor Housing. To inspect or replace the Carbon

Brushes, use a small standard screwdriver to remove

the Brush Covers. Then, carefully pull out the

Carbon Brushes. Examine the concave surface of

the Carbon Brushes.

If the Carbon Brushes appear to be in good condition,

but only dirty, they can be cleaned by rubbing with

a pencil eraser. If there are large scratches on the

Carbon Brushes, replace both Carbon Brushes

immediately with approved replacement Carbon

Brushes from Harbor Freight Tools. To reinstall the

Carbon Brushes, insert them into the two Brush

Holders. Turn the Carbon Brushes vertically so they

will fit properly into the Brush Holders. Then, replace

the Brush Covers. See Figure J, below.

5.

AFTER USE, wipe external surfaces

of the tool with clean cloth.

6.

WARNING! If the supply cord of this

power tool is damaged, it must be replaced

only by a qualified service technician.

Main Lock Plate

Figure I

Brush Cover, Carbon Brush and Brush Holder

Figure J