Maintenance – Craftsman 580.327270 User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MAINTENANCE

GENERAL RECOMMENDATIONS

The Owner/Operator is responsible for making sure that ail

periodic matniBnance tasks are completed on a timely

basis; thatall discrepancies are corrected; and that the unit

is kept clean and properly stored. Never operate a dam

aged or defective generator.

GENERATOR MAINTENANCE

Generator maintenance consists of keeping the unit dean

and dry. Operate and store the unit in a clean dry environ

ment VAihere it will not be exposed to excessive dust dirt

moisture or any corrosive vapors. Cooling air slots in the

generator must not become clogged with snow, leaves or

any other foreign material.

Check the cleanliness of the generator frequently and dean

when dust dirt oil, moisture or other foreign substances

are visible on its exterior surface.

NOTE: We DO NOT recommend\d using a garden hose

to clean the generator, Wator can enter the engine foe!

system and cause problems. In addition, if water enters the

generator through cooling air slots, some of the water will

be retained in voids and cracks of the rotor and stator

winding insulation. Water and dirtbuiid-up on tee generator

internal windings will eventually decrease tee insulation

resistance of teese windings.

TO CLEAN THE GENERATOR:

•

Use

3

damp dote to wipe exterior surfaces clean.

•

Use a soft bristle brush to loosen caked on dirt oil, etc.

•

A vacuum cleaner may be used to pick up loose dirt

and debris.

•

Low pressure air {not to exceed 25 psil may be used

to blowaway dirt Inspect cooling air slots and opening

on tee generator. These openings must be dirt clean

and unobstructed.

A

CAUTION: NEVER INSERT ANY OBJECTOR TOOL

THROUGH THE AIR COOLING SLOTS, EVEN IF

THE ENGINE IS NOT RUNNING. DAMAGE TO THE

UNIT OR PERSONAL INJURY MAY RESULT.

ENGINE MAINTENANCE

CHECKING OIL LEVEL

See OPERATION section on Page 4 for information on

checking oil level. Oil level should be checked before each

use or at least every five hours of operation. Keep oil level

maintained.

CHANGING OIL

Change oil after first

2

hours of opera lion. Change oil every

50 hours thereafter. If you are using your generator under

dirty or dusty conditions, or in extremely hot weather,

change oil more often.

CAUTION: DISCONNECT SPARK PLUG WIRE

FROM SPARK PLUG AND KEEP IT AWAY FROM

SPARK PLUG. DO THIS EVERY TIME YOU PER

FORM ANY MAINTENANCE ON THE ENGINE OR

THE GENERATOR.

Change oil while engine is still warm from running, se

follows;

• Clean area around oil drain plug, remove plug (Fig. 7)

and drain oil completely into a suitable container.

V№en oil has drained, install and tighten oil drain plug.

FIG. 7

•

Remove oil fill plug and insert a clean fill fennel into

plug opening. Fill engine crankcase with recom

mended oil until oil level is at point of overflowing.

About 21 ounces is required. POUR SLOWLY.

•

Wten engine crankcase is filled to proper level. Install

and tighten oil fill plug.

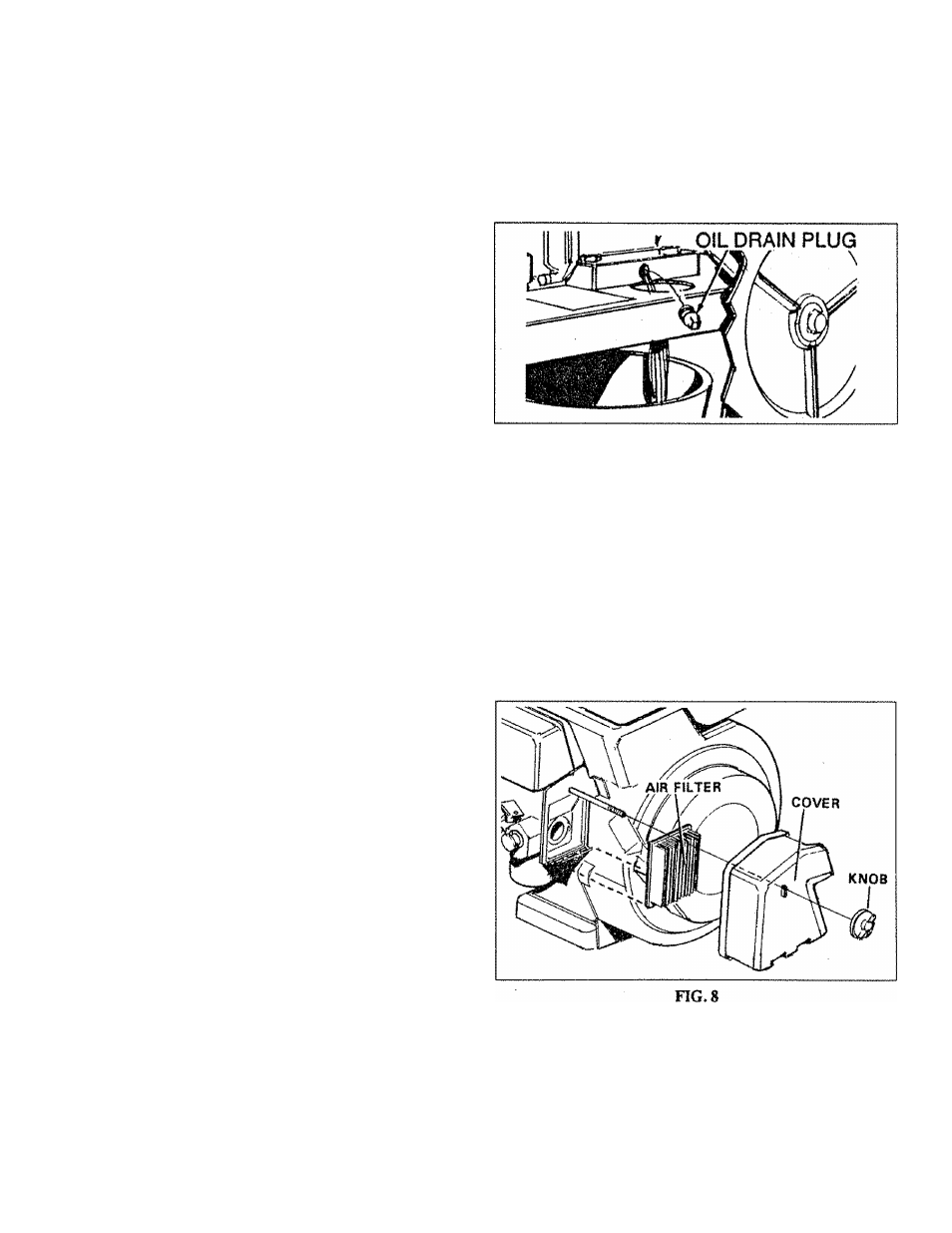

SERVICE AIR CLEANER

Your engine will not run properly and may be damaged if

you run it using a dirty air cleaner.

Clean or replace tee air cleaner paper filter (Fig. 81 once

every 1CX) hours of operation or once a year, whichever

comes first Clean or replace more often if operating under

dusty or dirty conditions.

A

CAUTION: NEVER RUN THIS UNIT WITHOUT THE

COMPLETE AIR CLEANER SYSTEM INSTALLED

ON THE ENGINE. THIS COULD RESULT IN PRE

MATURE WEAR TO THE ENGINE.