Service and adjustments, A warning – Craftsman 358.797310 User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

REPLACE FUEL FILTER

To replace fuel filter, drain unit by run

ning it dry of fuel, then remove fuel

cap/retainer assembly from tank. Pull

filter from tank and remove it from the

fuel line. Install new fuel filter on fuel

line; reinstall parts,

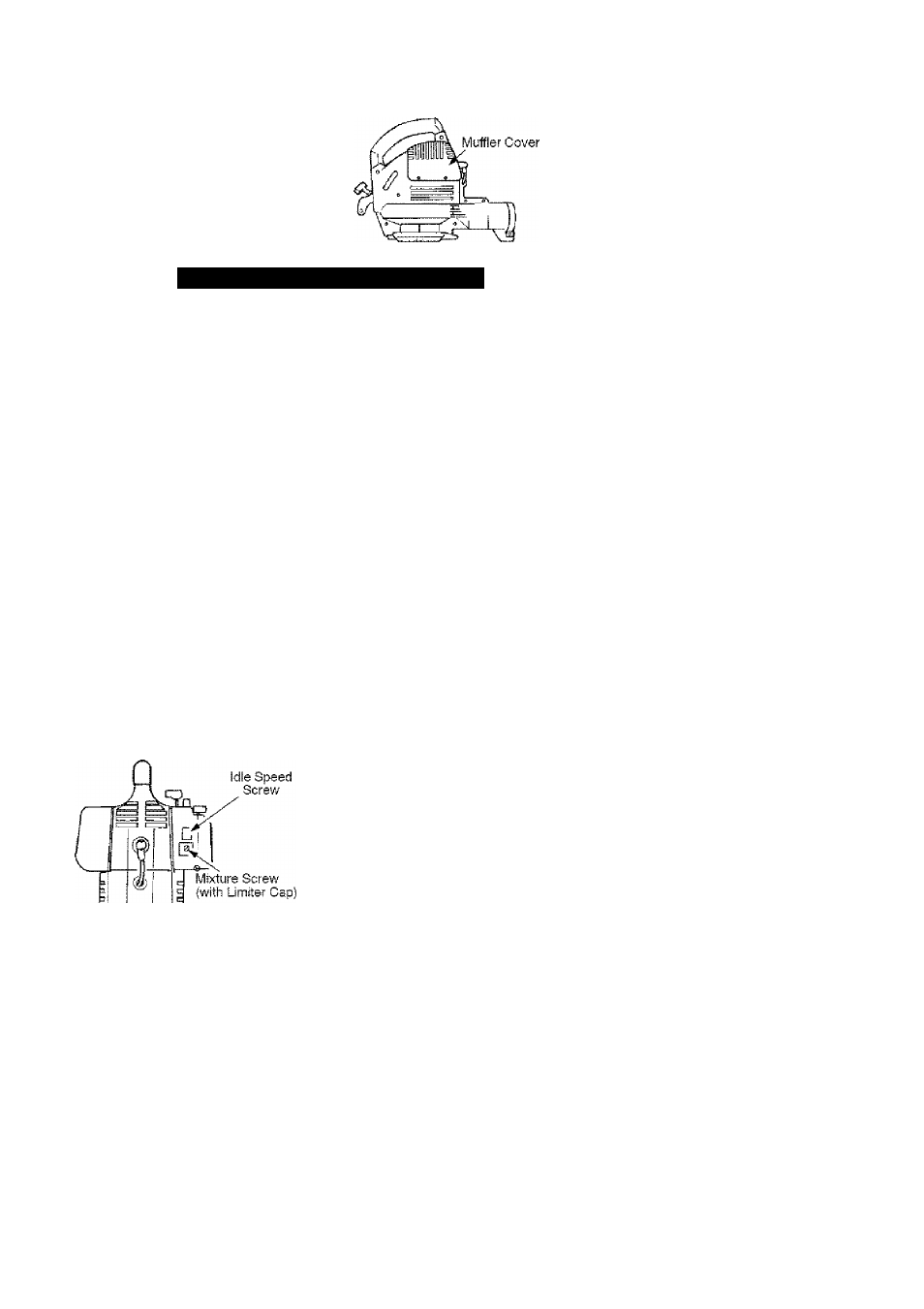

CHECK MUFFLER BOLTS

A WARNING:

Avoid touching muf

fler unless engine is cold. A hot muf

fler can cause serious burns.

Once each year, ensure muffler bolts

are secure and tightened properly to

prevent damage. Remove muffler cov

er and tighten the two muffler bolts

(100 in/ibs).

SERVICE AND ADJUSTMENTS

We recommend all service and adjust

ments not listed in this manual be per

formed by your Sears Service Center,

CARBURETOR ADJUSTMENT

Carburetor adjustment is critical and if

done improperly can permanently

damage the engine as well as the car

buretor. Sfyou require further assis

tance or are unsure about performing

this procedure, call our customer as

sistance help line at 1-800-235-5878.

Old fuel, a dirty air filter, a dirty fuel fil

ter, or flooding may give the impres

sion of an improperly adjusted carbu

retor. Check these conditions before

adjusting the carburetor.

The carburetor has been carefully set

at the factory. Adjustments may be

necessary if you notice any of the fol

lowing conditions:

• Engine will not idle. See IDLE SPEED

and MIXTURE under adjusting

procedure.

• Engine dies or hesitates instead of

accelerating. See ACCELERATION

CHECK under adjusting procedure,

• Loss of power. See MIXTURE under

adjusting procedure.

ADJUSTING PROCEDURE

CAUTION; Do not force plastic limiter

caps on screws beyond the built-in

stops or damage will occur.

Initial Settings

1. Turn the mixture screw counter

clockwise until it stops.

2. Turn the idle speed screw dock-

wise until it stops. Now turn coun

terclockwise 4-1/2 turns.

3. Start motor and let it run for 3 min

utes, then proceed to adjust

screws according to the instruc

tions below. If engine performance

at initial settings is acceptable, no

further adjustments are necessary.

If engine does not start, refer to

TROUBLESHOOTING TABLE. If

Still

unable to remedy situation, cail

1-800-235-5878.

Idle Speed “IDLE”

Allow engine to idle. Adjust speed until

engine runs without stalling.

• Turn IDLE screw clockwise to in

crease engine speed,

• Turn IDLE screw counterclockwise to

decrease engine speed.

Mixture “MIX”

Allow engine to idle. Then accelerate

the engine and note performance, if

engine hesitates, bogs down, or

smokes during acceleration, turn MIX

screw clockwise in 1/16-turn incre

ments until performance is satisfactory.

Repeat this procedure as necessary

tor proper adjustment. After completing

adjustments, check tor acceleration.

Reset if necessary.

Acceleration Check

It engine dies or hesitates instead of

accelerating, turn MIX screw counter

clockwise until you have smooth acoel-

eralion.

10