Maintenance, General recommendations, Before each use – Craftsman 917.272240 User Manual

Page 18: Lubrication chart

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MAINTENANCE

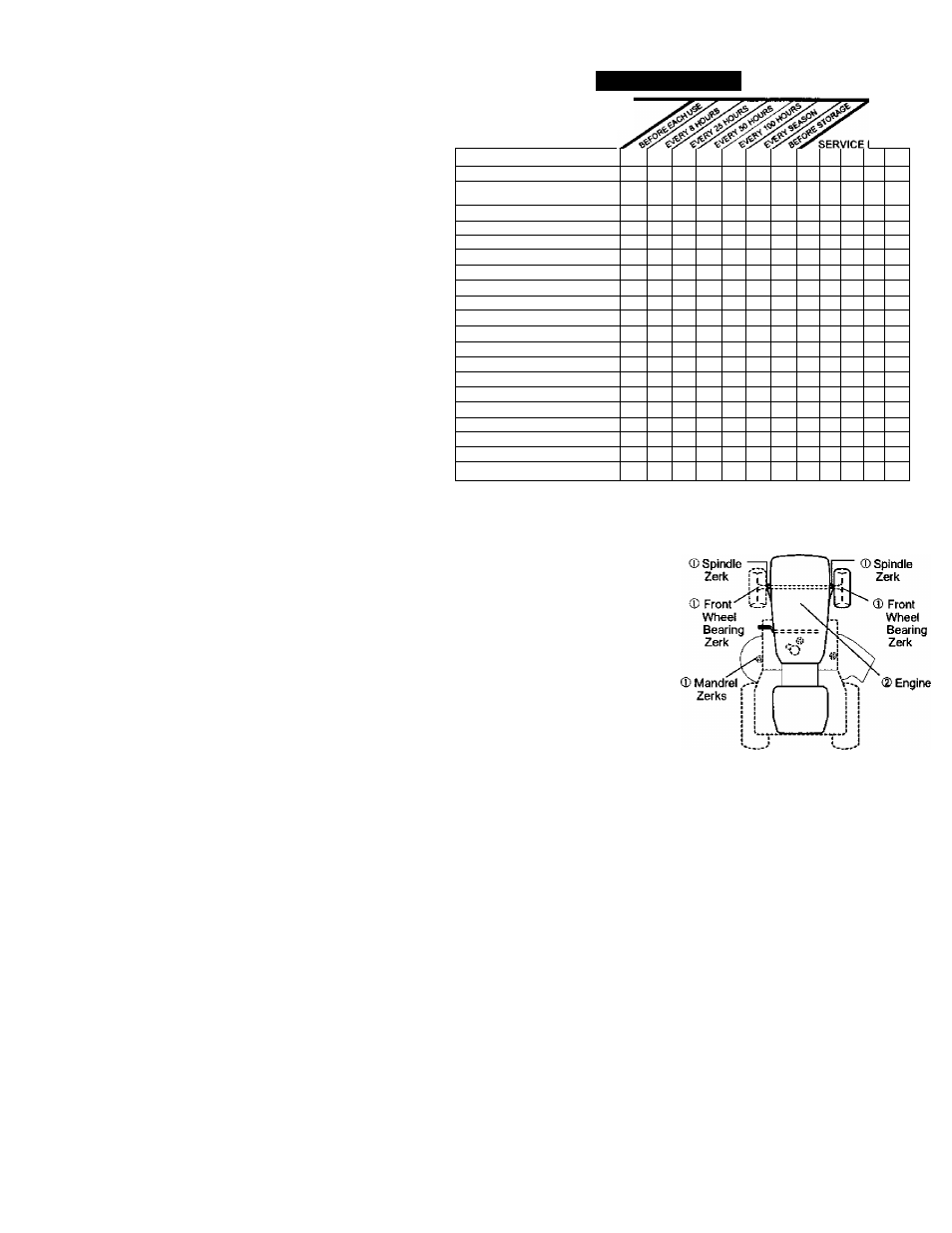

MAINTENANCE SCHEDULE

.L

IN

OATES

FILL

IN

DATES

AS YOU COMPLETE

AS YOU COMPLETE

REGULAR

SBtWiCE

ChBdt Brake Operation

✓

✓

Check Tire Pressure

✓

Check Operator Presence and

Interlock Systems

✓

Chech for Loose Fasteners

✓

✓

Sharperi/Replace Mower Blades

Lubrication Chari

✓

✓

Chech Battery Level

Clean Battery and Terminals

✓

✓

Check Transaxle Cooling

✓

Adjust Blade BeH(s) Tension

Adjust Motion Drive BeK(s) Tension

Check Engine Oil Level

✓

✓

Change Engine Oil

✓

Clean Air Filter

Clean Air Screen

Inspect MufTler/Spark Arrester

✓

Replace Oil Filter (If equipped!

t

/.2

Clean Engine Cooling Fins

Replace Spark Plug

✓

✓

Replace Air Filter Paper Cartridge

Replace Fuel Filter

✓

1 -№«rp*inoraoflar wh»n opcreiins und«r » haevy loed or in Ngh emNenl tempentuT»».

2 - S«n^a more often when opereSnfi In dirty ordusty condltione.

3 • If equipped wHh oil iHter, chengeod every &0 hours.

4 - Replace Nedes mors often when mowing |n sandy sod.

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover

Herns that have been subjected to operator

abuse or negligence. To receive fuli value

from the warranty, operator must maintain

tTeictor as instructed in this manual.

Some adjustments will need to be made

periodically to properly maintain your

tractor.

All adjustments in the Smice and

Adjustments section of this manual should

be checked at least once each season.

• Once a year you should replace the

spark plug, clean or replace air filter, and

check blades and belts for wear. A new

spark plug and clean air filter assure

proper air-fuel mixture and help your

engine run better and last longer.

BEFORE EACH USE

1. Check engine oil level.

2. Check brake operation.

3. Check tire pressure.

4. Check operator presence and

interlock systems for proper operation.

5. Check for loose fasteners.

- If »quipp*«! with adjustable system.

■ Not required if equipped w№ mairtenar>ce-frea baltary.

7 -Tighten frori axle phrcH bolt to 3&ft.-t96. mawum.

Oo not overtighten.

LUBRiCATION CHART

18

® General Purpose Grease

® Refer to Maintenance "ENGINE" Section

IMPORTANT: Do not oil or grease the

pivot points which have special nylon

bear-Ings. Viscous lubricants will attract

dust and dirt that will shorten the life of

the self-lubricating bearings. If you feel

they must be lubricated, use only a dry,

powdered graphite type lubricant

sparingly.