Assembly instructions, Items you will need to assemble your compressor, Installing handle – Craftsman 919.17673 User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Pressure Switch: The pressure switch automaticaily

starts the motor when the air tank pressure drops below

the factory set “cut-in" pressure. It stops the motor when

the air tank pressure reaches the factory set “cut-out"

pressure.

Regulator: The air pressure coming from the air tank is

controlled by the regulator knob. Turn the knob

clockwise to increase pressure and counterclockwise to

decrease pressure. To avoid minor readjustment after

making a change in pressure setting, always approach

the desired pressure from a lower pressure. When

reducing from a higher to a lower setting, first reduce to

some pressure less than that desired, then bring up to

the desired pressure. Depending on the air requirements

of each particular accessory, the outlet regulated air

pressure might have to be adjusted while you are

operating the accessory.

Tank Pressure Gauge: The tank pressure gauge indi

cates the reserve air pressure in the tank.

Outlet Pressure Gauge: The outlet pressure gauge

indicates the air pressure available at the outlet side of

the reguiator. This pressure is controlled by the regulator

and is always less or equal to the tank pressure. See

“Operating Procedures.”

ASSEMBLY INSTRUCTIONS

Items You Will Need To Assemble Your

Compressor

• 16 oz. compressor oil. Sears 9-16426 or SAE 20-20W

SF motor oil

• pipe thread sealant

• an adjustable wrench for attaching the pressure

regulator

• a 9/16" socket or open-end wrench for attaching the

wheels and hose adapter

• a 7/16" open-end wrench for attaching the air pressure

gauges

• a 3/16" hex key for installing the plug in the regulator

Installing Handle

W A R N I N G

]

THE WHEELS HAi^lDLE DO NOT PRO

VIDE ADEQUATE CLEARAriCE. STAS?LITY

C.SR SOPPORT FOR PyUJMG THE Uf--J!T UP

Am DO\m

smiHS

or

-

step

-

s

.

the

unit

MUST BE LiPTED OR PUSHED UP

A fiAMP.

DO MOT LiFT THE Ul^iT BY THE MANIFOLD

A.SSEfyiBLy. THE UM!T

CAM

BE DAMAGED,

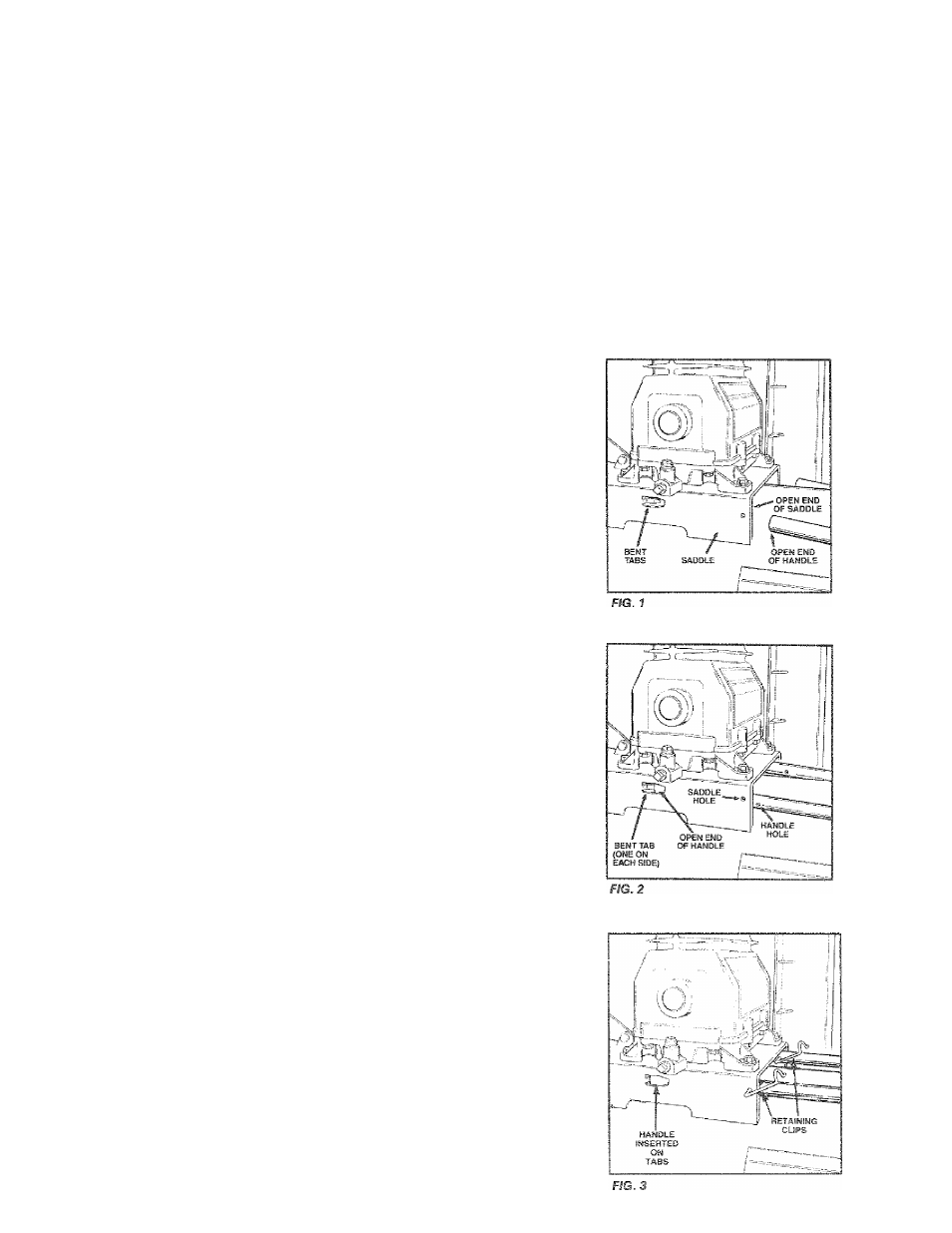

1 Insert the open end of the handle under the saddle (Fig.

1). Before attaching handle, you may have to pull the

open ends of the handle apart so they fit tightly against

the side of the saddle. Looking in from the open end of

the saddle, position the handle towards the two bent

tabs, on the inside walls of the saddle.

Slowly

push the

open ends of the handle onto both tabs at the same

time (Fig. 2). Continue pushing the handle into the sad

dle until the holes on the side of the saddle and handle

are in line.

2. Guide the straight end of each retaining clip through the

saddle hole and both handle holes (Fig. 3).

3. Rotate each retaining clip clockwise and press down

until it snaps into place over the puli handle (Fig. 4).

4. If the handle has excessive movement, it is improperly

installed. Check the following;

A. Are both tabs inside the handle (Step #1)?

B. Does each dip pass through both the saddle and

handle (Step #2)?