Craftsman 917.253724 User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

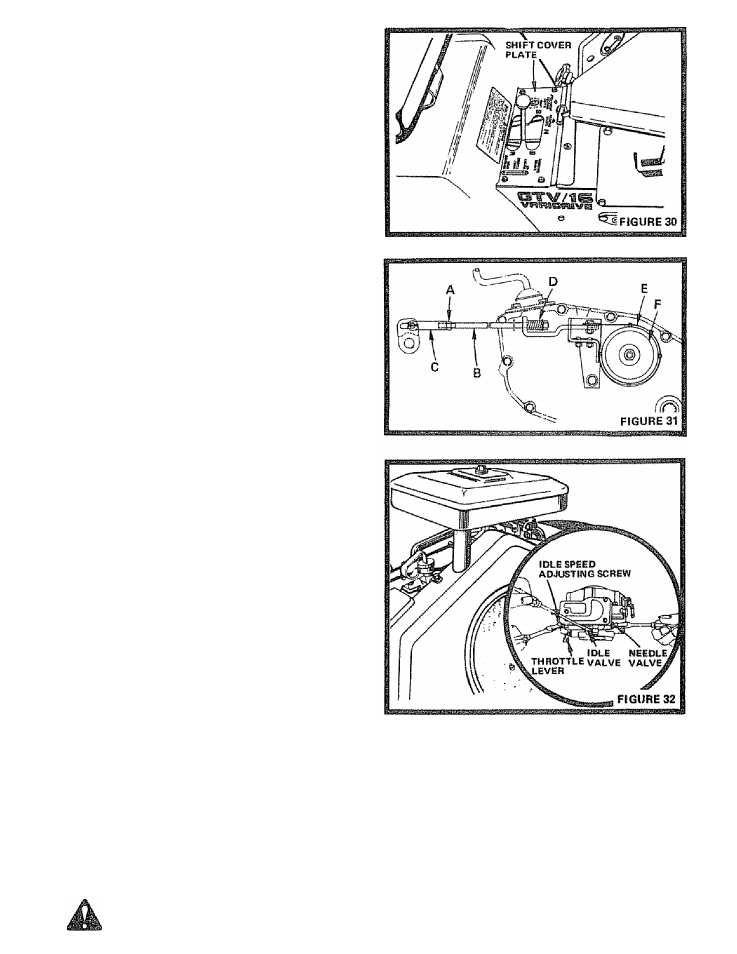

2. BRAKE ADJUSTMENT

A

IF TRACTOR REQUIRES MORE THAN

SIX FEET STOPPING DISTANCE IN

HIGHEST GEAR ON A LEVEL DRY

concrete

OR PAVED SURFACE THEN

BRAKE MUST BE ADJUSTED.

a.

Remove (4} Hex Washer Head Tapping Screws from

Shift Cover Plate (Fig. 30), located on top tractor frame.

Remove the Cover Plate.

b.

Loosen Jam Nut (A) on Brake Rod (B) at Clevis (C|

(Fig,31)

c

Rotate

Brake

Rod

(B)

counterclockwise,

turning

Brake Rod out of Clevis (C) four to six turns (Fig. 31).

d.

Start tractor with Transmission in NEUTRAL posi

tion ,

e.

Depress Brake-Clutch Pedal to the point where Secon

dary Belt (Fig 16) stops moving. Hold Brake-Clutch

Pedal in position by engaging Parking Brake (Fig, 10)

If Secondary Balt begins to move after engaging Parking

Brake, depress Brake«Ctutch Psctal to next notch on

Parking Brake.

f.

Shut engine off. Rotate Brake Rod (B) clockwise by

hand, turning Brake Rod into Clevis iC), until tight.

Tighten .Jam Nut (A) on Brake Rod (B) at Clevis (C)

(Fig. 31!.

CARBURETOR ADJUSTMENT

Never attempt to change maximum engine speed- This is

preset at the factory and should only be changed fay a quali

fied service technician who has the necessary equipment,

a. Adjust Carburetor to suggested initial settings.

-

Turn Needle Valve clockwise ( O ) closing finger

tight

ONLY,

and

then

turn

counterclockwise

}

1-1/2 turns (Fig, 32).

-

Turn Idle Valve clockwise, (C™t) closing finger tight

ONLY, and then turn counterclockwise (|0) 1 - 1/2

turns,

CAUTION; Valves may be damaged if turned in too far.

A

REFER TO

PAGE 4.

"STARTING THE ENGINE*

b. Start Engine and allow to warm for five minutes. Make

final adjustments with Engine running,

With

Throttle

Control

in

’*SLOW’*

position,

hold

Throttle Lever against idle Stop and set Idle Speed

Adjusting Screw to give an engine speed of 1400

RPM. Turn Idle Valve clockwise (k^! slowly until

engine begins to miss and then open 1/2 turn counter

clockwise If^)

- Set Idle Speed Screw to give engine speed of 900

RPM. When Throttle Lever is release from Idle

Stop, engine speed should be between 1000 and 1400

RPM, controlled by governor

NOTE; ALL ABOVE SPEED AND FUEL MIXTURE

ADJUSTMENTS MUST BE DONE WITH THE

THROTTLE

lever

HELD AGAINST THE IDLE

STOP AND AT SPEEDS NOTED.

-

With

Throttle

Control

in

"FAST*'

position,

turn

Needle Valve slowly clockwise (r>) until engine be

gins to miss and then set 1/2 turn counterclockwise,

(r»). NOTE: !F ENGINE HESITATES WHEN MOV

ING

THROTTLE

CONTROL

FROM

"SLOW"

TO

"

fast

"

POSITIONS,

TURN

NEEDLE

VALVE

COUNTERCLOCKWISE ( (^ ) 1/8 TURN MORE.

ADJUSTMENT V-BELT

It

may be occasionally necessary to re-adjust V-Belt (See

page 7).

CHECK TO MAKE SURE TRACTOR DOES

NOT START WITHOUT FULLY DEPRESS

ING CLUTCH-BRAKE PEDAL-

11