Craftsman 358.795543 User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SERVICE AND ADJUSTMENTS

LINE REPLACEMENT

Pre-wound spools offer the most con

venient method for replacing line and

ensuring optimum performance,

• Replacement spools are color-

coded to ensure use of the correct

spool with your unit. Be sure to use

the same color spool as the existing

spool,

NOTE: Always clear dirt and debris

from cutting head components when

performing any type of maintenance,

• Hold spool and unscrew cap by turn

ing in the direction shown on top of

the cap,

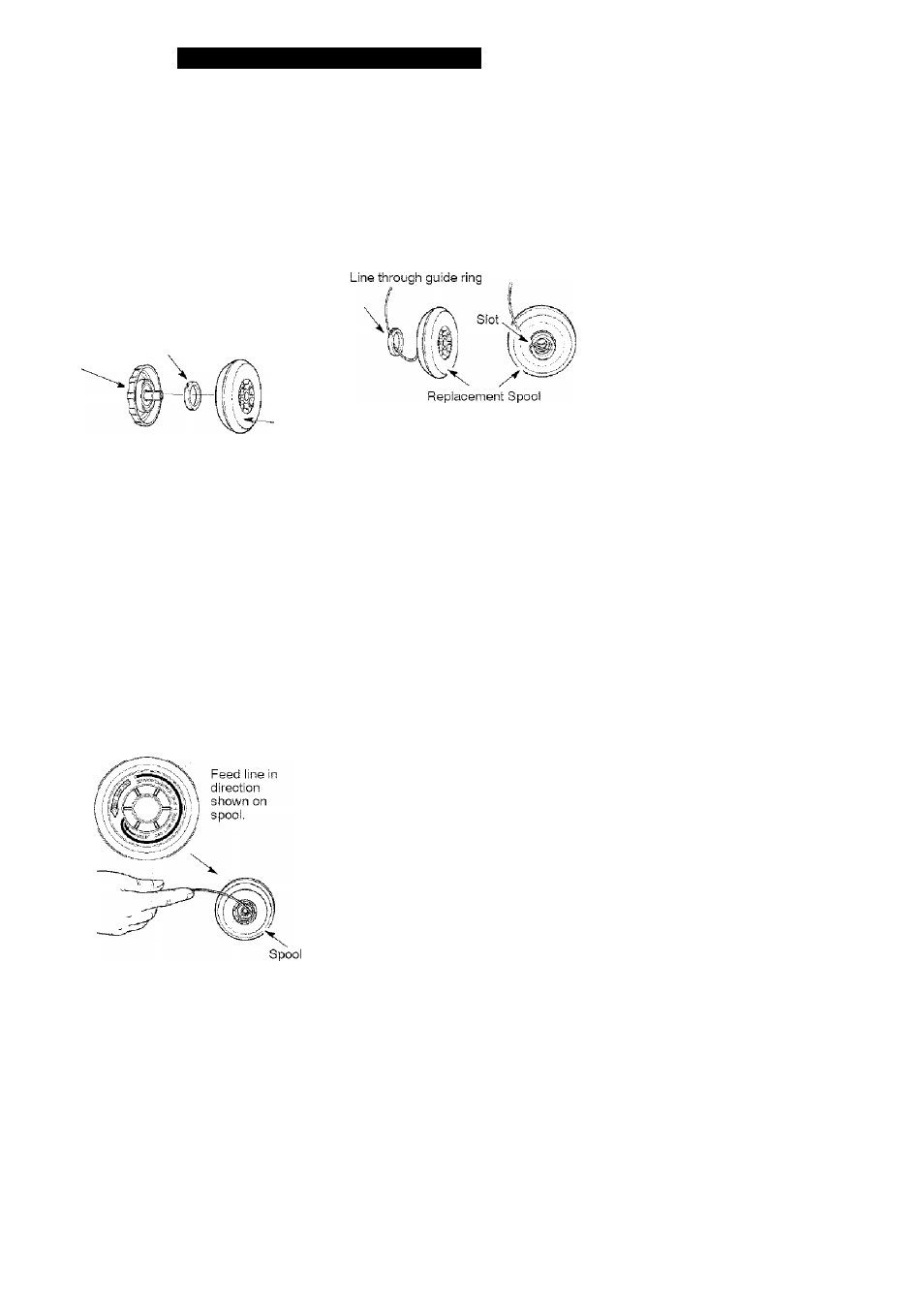

• Remove line guide ring and spool.

Line guide ring

Cap

'

Spool

Use a pre-wound spool or refill spool

with line. If using a pre-wound spool,

remove tape strip from line and spool.

REFILLING THE SPOOL WITH LINE

A WARNING:

Use only 0.080

inch (2 mm) diameter round line.

Other sizes and shapes of line will not

advance properly and will result in im

proper cutting head function or can

cause serious injury. Do not use other

materials such as wire, string, rope,

etc. Wire can break off during cutting

and become a dangerous missile that

can cause serious injury.

1. Cut a length of 25 feet of 0.080 inch

(2 mm) diameter round Crattsman

brand line.

2. Insert one end of line into center

cavity of empty spool. Ensure line

will feed into spool in the direction

shown on the spool (counterclock

wise).

3. Continue feeding line into spool,

leaving 4-6 inches (10 - 15 cm)

unwound from center of spool.

INSTALLING SPOOL WITH LINE

1. Install replacement spool.

2. Thread line through line guide ring.

3. Rest guide ring on spool and place

line through slot. Allow line to ex

tend 4-6 inches (10 - 15 cm) from

center of spool.

4. Ensure line remains in slot while

screwing cap on to the shaft. Only

tighten cap hand tight!

CARBURETOR ADJUSTMENT

A

w

ARNING:

Keep others away

when making idle speed adjustments.

The trimmer head will be spinning dur

ing this procedure. Wear your protec

tive equipment and observe all safety

precautions.

The carburetor has been carefully set

at the factory. Adjustments may be

necessary if you notice any of the fol

lowing conditions:

• Engine will not idle when the throttle is

released.

Make adjustments with the unit sup

ported so the cutting attachment is off

the ground and will not make contact

with any object. Hold the unit by hand

while running and making adjust

ments. Keep all parts of your body

away from the cutting attachment and

muffler.

Idle Speed Adjustment

Allow engine to idle. Adjust speed until

engine runs without stalling (idle

speed too slow).

• Turn idle speed screw clockwise to

increase engine speed if engine

stalls or dies.

10