Installing bits, Removing bits, Using depth gage rod – Craftsman 315.271270 User Manual

Page 10: Assembly

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ASSEMBLY

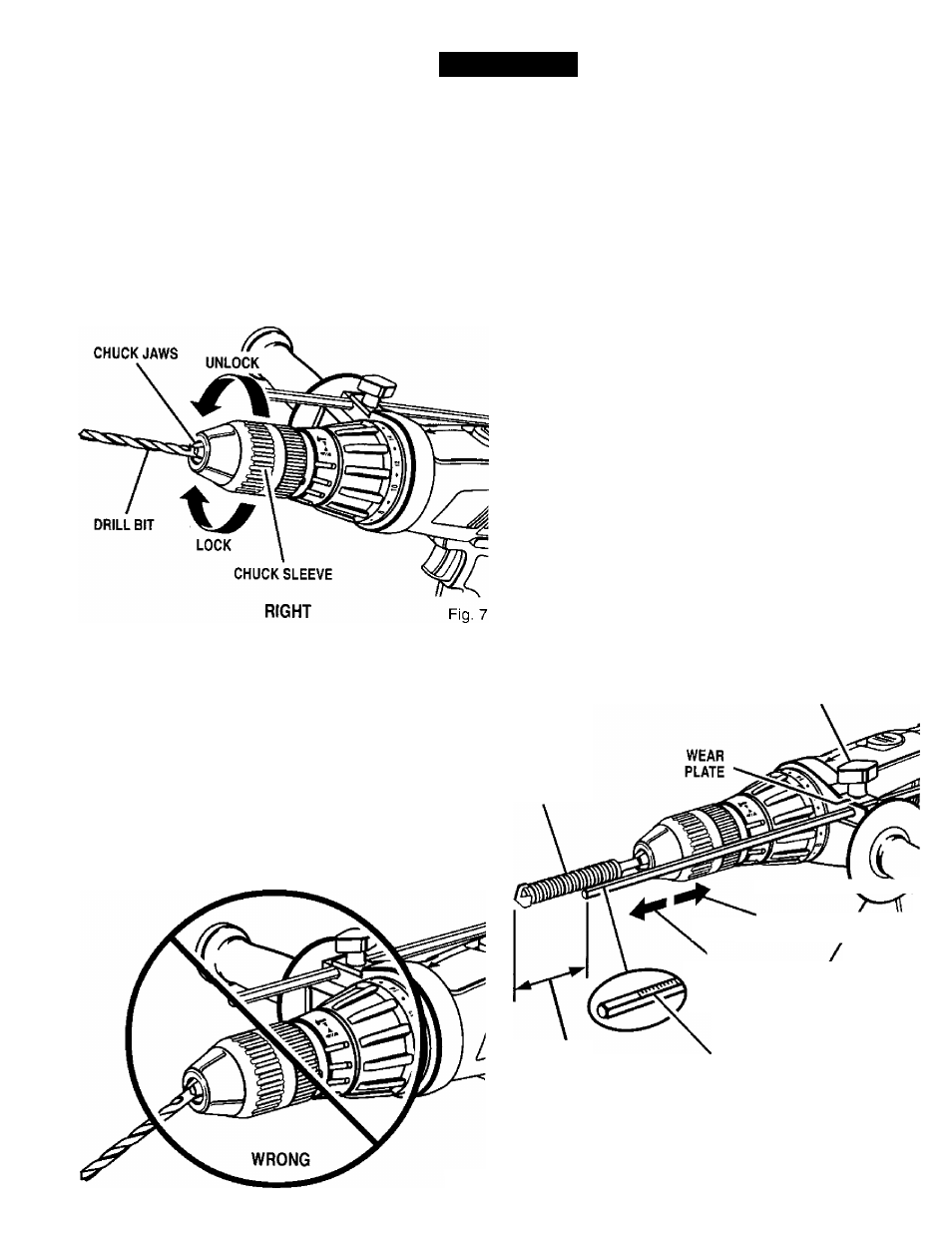

INSTALLING BITS

See Figure 7.

■

Lock the switch trigger by placing the direction of

rotation selector in center position. See Figure 13.

■

Open or close chuck jaws to a point where the open

ing is slightly larger than the bit size you intend to use.

Aiso, raise the front of your drill slightly to keep the bit

from falling out of the chuck jaws.

■

Insert drill bit into chuck the full length of the jaws as

shown in Figure 7.

Tighten the chuck jaws on drill bit. To tighten, grasp

and hold the drill with one hand, while rotating the

chuck sleeve with your other hand.

Note:

Rotate the chuck sleeve in the direction of the

arrow marked

LOCK

to tighten chuck jaws.

Do not

use a wrench to tighten or loosen the chuck

jaws.

^ WARNING:

Do not insert driil bit into chuck jaws

and tighten as shown in Figure 8. This could cause

drill bit to be thrown from drill resulting in possible

serious personal injury or damage to the chuck.

REMOVING BITS

See Figure 7.

■

Lock the switch trigger by placing the direction of

rotation selector in center position. See Figure 13.

■

Loosen the chuck jaws from drill bit.

■

To loosen, grasp and hold the drill with one hand,

while rotating chuck sleeve with your other hand.

Note:

Rotate chuck sleeve in the direction of the arrow

marked

UNLOCK

to loosen the chuck jaws.

■

Do not

use a wrench to tighten or loosen the chuck

jaws.

■

Remove drill bit from chuck jaws.

USING DEPTH GAGE ROD

See Figure 9.

A depth gage rod has been packed with your hammer drill

to assist you in controlling the depth of drilled holes.

■

Loosen wing screw on auxiliary handle.

■

Orient depth gage rod so that markings on depth gage

rod face markings on wear plate. See Figure 4. Insert

depth gage rod through hole on auxiliary handle.

■

Adjust depth gage rod so that the drill bit extends

beyond the end of the rod to the required drilling

depth.

■

Tighten wing screw securely. This secures depth

gage rod at desired depth of cut. It also secures

auxiliary handle.

WING

SCREW

DRILL BIT

DRILLING

DEPTH

TO

INCREASE

DRILLING

DEPTH

■ TO

DECREASE

DRILLING

AUXILIARY

DEPTH

HANDLE

MARKINGS ON

DEPTH GAGE ROD

Fig. 9

Fig. 8

When drilling holes with the depth gage rod installed, the

desired hole depth has been reached when the end of the

rod comes in contact with the surface of the material

being drilled.

10