Craftsman 917.273823 User Manual

Page 20

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

* Keep battery bolts tight.

* Keep small vent holes open.

* Recharge at 6-10 amperes for 1 hour.

NOTE: The original equipment battery on

your tractor is maintenance free. Do not

attempt to open or remove caps or covers.

Adding or checking level of electrolyte is

not necessary.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and

terminals can cause the battery to ‘leak”

power.

1. Disconnect BLACK battery cable first

then RED battery cable and remove

battery from tractor.

2. Rinse the battery with plain water and

dry.

3. Clean terminals and battery cable ends

with wire brush until bright

4. Coat terminals with grease or petro

leum jelly.

5. Reinstall battery {See “REPLACING

BATTERY" in the Service and Adjust

ments section of this manual).

TRANSAXLE COOLING

The transmission fan and cooling fins

should be kept dean to assure proper

cooling.

Do not attempt to dean fan or transmis

sion while engine is running or while the

transmission is hot To prevent possible

damage to seals, do not use high pressure

water or steam to clean transaxle.

* Inspect cooling fan to be sure fan blades

are intact and clean.

* Inspect cooling fins for dirt, grass clip

pings and other materials. To prevent

damage to seals, do not use com

pressed air or high pressure sprayer to

clean cooling fins.

TRANSAXLE PUMP FLUID

The transaxle was sealed at the factory

and fluid maintenance is not required for

the life of the transaxle. Should the trans

axle ever leak or require servicing, contact

a Sears or other qualified service center.

V-BELTS

Check V-belts for deterioration and wear

after 100 hours of operation and replace

if necessary. The belts are not adjustable.

Replace belts if they begin to slip from

wear.

ENGINE

LUBRICATION

Only use high quality detergent oil rated

with API service ciassification SG-SL.

Select the oil's SAE viscosity grade

according to your expected operating

temperature.

SA£ VtSCOSiTY GRADES

C -00__________ -20 -to_______________ 0________ 10________ 20_______

30 4Q

TEMPERATXiRE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

NOTE: Although multi-viscosity oiis

(5W30, 10W30 etc.) improve starting in

cold weather, they will result in increased

oil consumption when used above 32T.

Check your engine oil level more frequent

ly to avoid possible engine damage from

running low on oil.

Change the oil after every 50 hours of op

eration or at least once a year if the tractor

is not used for 50 hours in one year.

Check the crankcase oil level before start

ing the engine and after each eight {8)

hours of operation. Tighten oil fill cap/

dipstick securely each time you check the

oil level.

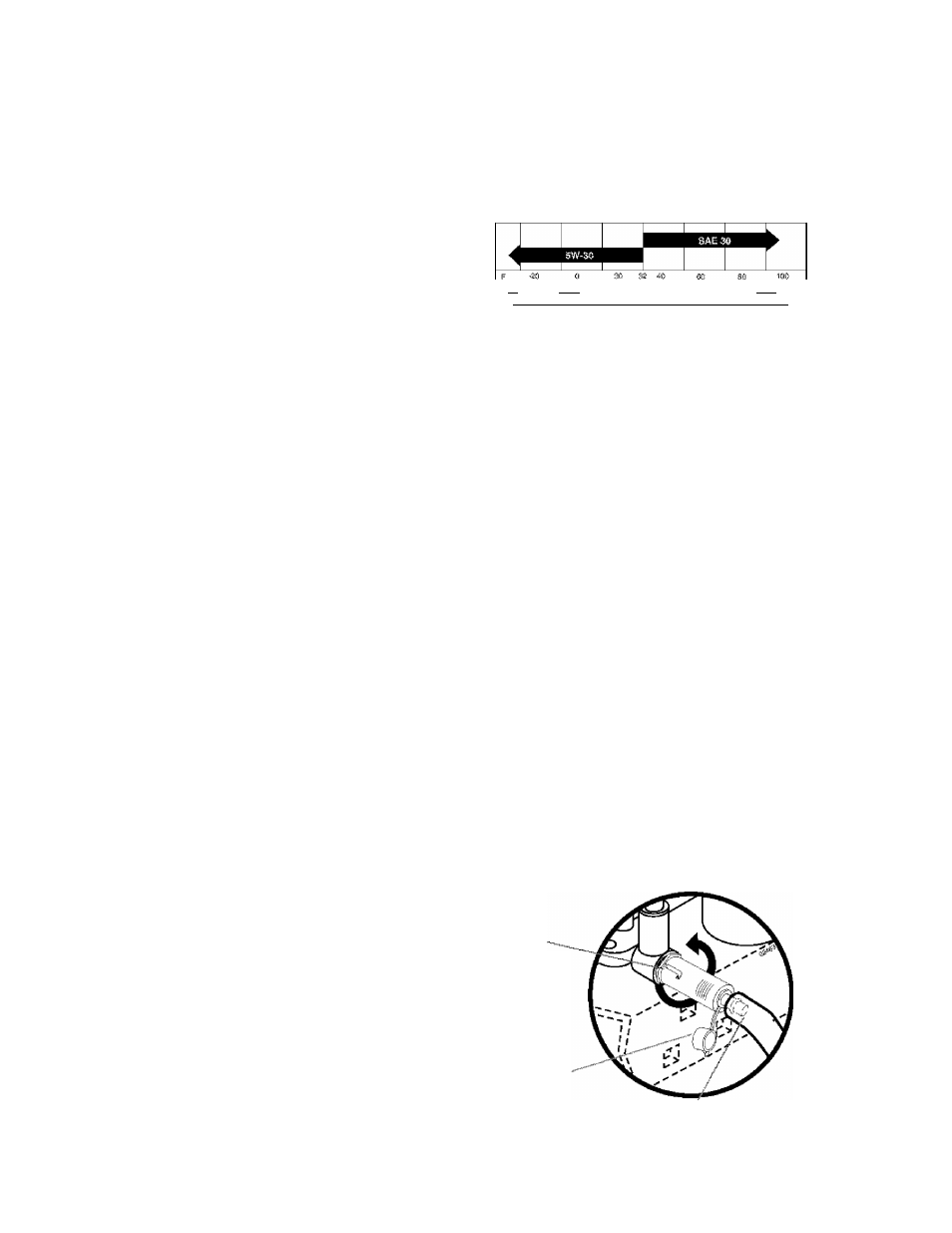

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. All oil must meet API

service classification SG-SL.

* Be sure tractor is on level surface.

* Oil will drain more freely when warm.

* Catch oil in a suitable container.

1. Remove oil fill cap/dipstick. Be careful

not to allow dirt to enter the engine

when changing oil.

2. Remove yellow cap from end of drain

valve and install the drain tube onto the

fitting.

Oil Drain Valve

Closed

and

Locked

Position

Yeliow Cap

Drain Tube

20