Checking cutter blades – Craftsman 149.236321 User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

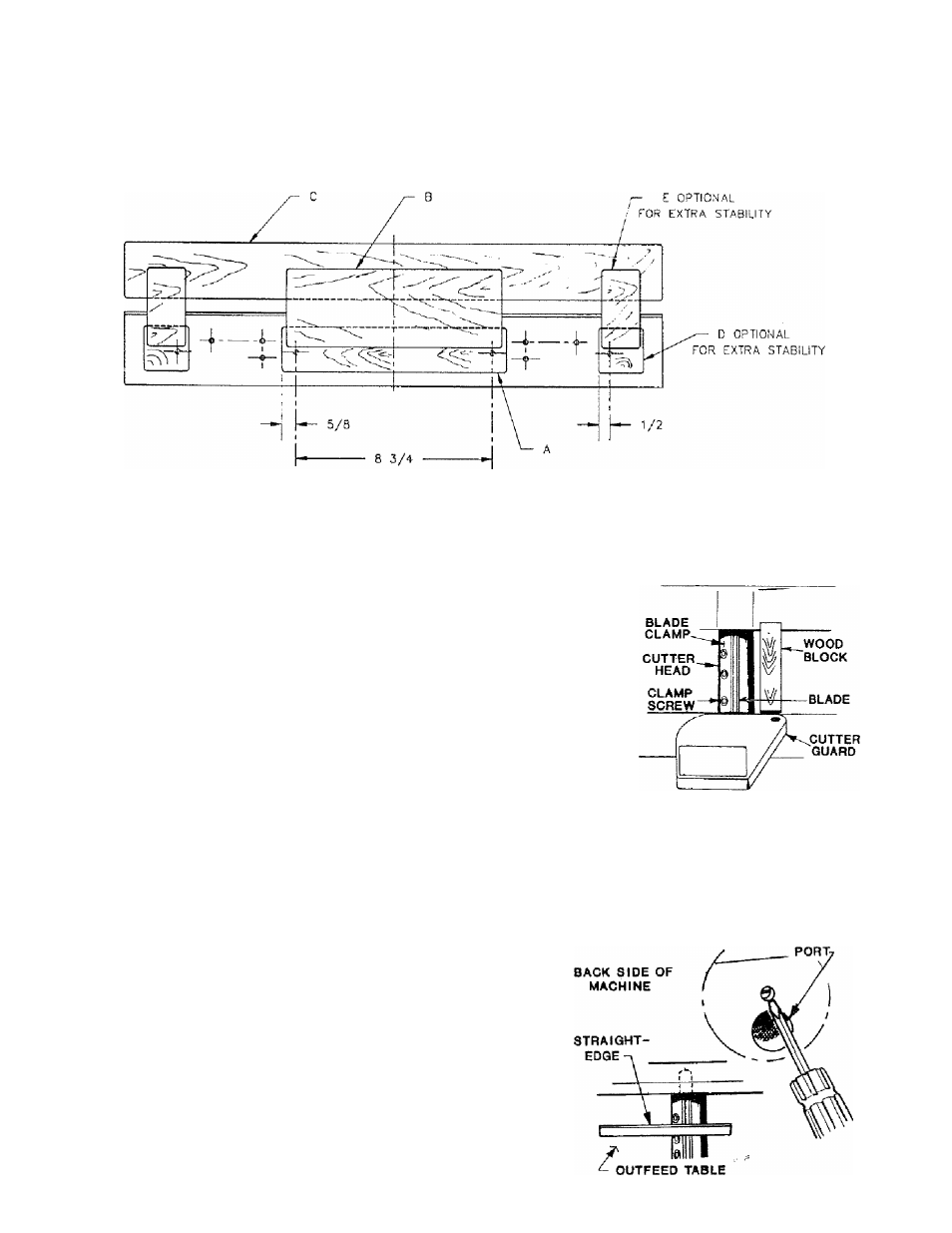

A= 11/16 Thick

X

2'Wide

X

10" Long

The 11/16 thickness can be obtained by pianing the board

on the Jointer-planer.

B= 1/2" to 3/4" Thick

X

3-1/2" Wide x 10" Long

This piece may also be made out of plywood.

,C= 3/4" Thick X 2-1/2" Wide x 19-1/2" Long

' The 2-1/2" width may be increased if desired.

OPTIONAL — For Extra Stability

D= 11/16" Thick

X

2" Wide x 2" Long, 2 Pieces

E= 1/2" to 3/4" Thick

X

3-1/2" Wide x 2" -»■ Long, 2 Pcs.

NOTE: Cut both 0 pieces from the same stock or thickness as

board A and cut both E pieces from the same stock or thickness

as board B.

CHECKING CUTTER BLADES

4

CAUTION: MAKE SURE THE SWITCH IS IN THE OFF POSITION

AND CORD IS UNPLUGGED BEFORE PROCEEDING WITH CHECK

ING CUTTER BLADES.

The blades in your Jointer-Planer have been adjusted at the factory to

assure proper operation. Shipping and handling, however, may cause

misalignment. For accurate cutting, the blades must be .003-In. higher

than the outfeed table (thickness of a piece of paper) when positioned at

the highest point.

1.

Block the cutter guard open with a scrap piece of wood about 5-1/2"

long between the fence and cutter guard.

CHIP DISCHARGE/VACUUM

2.

Locate the slot in the cutter head shaft through the small hole in the

backside of the machine directly above the vacuum port. Rotate the

cutter head with a screwdriver until one of the blades Is at its highest

position.

3.

place a straight edge over the outfeed table and the blade. The

straight edge must touch evenly on the outfeed table at both ends of

the blade. Rotate the cutterhead slowly, and making sure the blade

lightly touches the straight edge. If the straight edge rises or blades

do not touch, follow the "REPLACING CUTTER BLADES" procedure

in the “MAINTENANCE” section.