A warning, Removing the flail screen, And maintenance – Craftsman 247.776370 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

AND MAINTENANCE

A WARNING

Before performing any type of maintenance on the machine, wait for

all parts to stop moving and disconnect the spark plug wire. Failure

to follow this instruction could result in personal injury or property

damage.

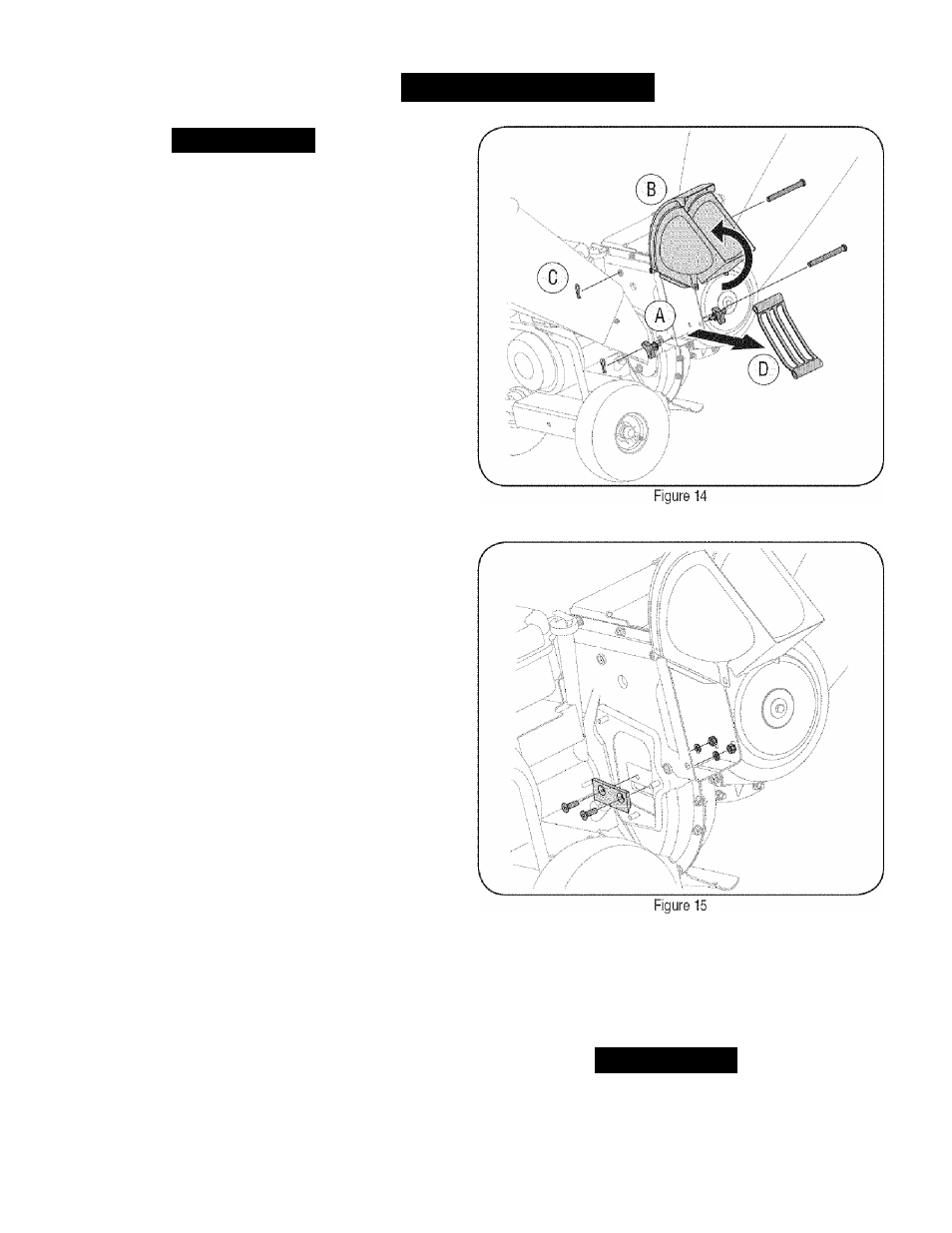

REMOVING THE FLAIL SCREEN

If the discharge area becomes clogged, remove the flail screen and

clean area as follows:

1.

Stop the engine. Make certain the chipper shredder has come to

a complete stop.

2.

Disconnect spark plug wire from spark plug and ground against

the engine.

3.

a. Remove the bag and two wing knobs on each side of the chute

deflector. See Figure 14.

b. Lift the chute deflector up to keep it out of the way.

c. Remove the two hairpin clips from each clevis pin which extend

through the housing and remove pins.

d. Remove the flail screen from inside the housing and clean the

screen by scraping or washing with water. See Figure 14.

4. Reinstall the screen, making certain to reassemble the flail screen

with the curve side down.

5. Reattach the chute deflector with the hardware previously removed

and connect the bag to unit.

SHARPENING OR REPLACING CHIPPER

BLADES

1.

Disconnect the spark plug wire and ground against the engine.

2.

Remove the flail screen as instructed in the previous section.

3.

Remove the chipper chute by removing three hex nuts and

washers.

4.

Remove the chipper chute support brace from the frame by

removing the hex bolts.

5.

Rotate impeller assembly by hand until you locate one of two

chipper blades in the chipper chute opening.

6.

Remove the blade by removing the internal hex screws, lock

washers, and hex nuts which secure it to the impeller. Retain the

hardware. See Figure 15.

NOTE: Use a 3/16” hex key (Allen) wrench on the outside of the blade

and a 1/2” box (or socket) wrench on the inside of the impeller. Hold

the Allen wrench stationary and rotate the box (or socket) wrench to

loosen the nut.

7. install a replacement blade (Part No. 781-0490) with the hardware

removed earlier or sharpen.

IMPORTANT: When sharpening the blade, protect hands by using

gloves. Follow the original angle of grind and make sure to remove an

equal amount from each blade.

8.

To replace the other blade, rotate the impeller to expose the

second blade and repeat the steps above.

NOTE: Make certain blades are reassembled with the sharp edge

facing upward. Torque hardware to 250 - 300 in. lbs.

A

warning

The impeller’s chipper blades and shredder blade are sharp. Wear

leather work gloves to protect your hands.

16