Specifications, Unpacking, Installation – Chicago Electric 42933 User Manual

Page 10

SKU 42933

For technical questions, please call 1-800-444-3353.

Page 10

ReV 01c

SpecIFIcAtIOnS

Power

Requirements

120 V~, 60 Hz, 1-ph

20.9 A (start); 6.9 A (load); 1330 W

Motor

1-3/4 HP, 4200 spindle RPM,

electric brake

Saw Blade

8-1/4” (dia.)

Arbor

5/8”

Crosscut Distance 11” (maximum)

Rip Cut Distance 20” (maximum)

Depth of Cuts

45°: 2”; 90°: 2-1/8”

Bevel Index Stops 0, 45, 90°

Mitre Index Stops Left and right: 0, 15, 30, 45, and 60°

Table Size

15-1/16 x 27-5/8 x 3/4”

Accessories

Blade Replacement: Item # 43204

note: Performance of this tool may vary

depending on variations in local line

voltage. Extension cord usage may

also affect tool performance.

unpAckIng

When unpacking, check to make sure

that all the parts are included. Refer to the

Parts List and Assembly Drawing at the

end of this manual. If any parts are miss-

ing or broken, please call Harbor Freight

Tools at 1-800-444-3353 as soon as pos-

sible.

InStALLAtIOn

During the assembly and installation

procedure, you may have to refer to the

Parts List and Assembly Drawings located

at the end of this manual.

Secure the Radial Arm Saw to a solid

1.

bench top (or table) by bolting (or

clamping) the saw frame down to the

bench top.

The workbench must not be able to

•

slide or tip over. Affix to floor if nec-

essary.

Position the Radial Arm Saw (or saw

•

and bench) to slope slightly to the

rear so the radial arm carriage will

not roll forward due to gravity.

The workbench should be of the ap-

•

propriate length and width to allow

the operator to stand aside of the

saw blade, whatever position the

saw blade is in.

The work area should have ade-

•

quate, overhead, non-glare lighting.

Lock the radial arm carriage before

•

moving the unit.

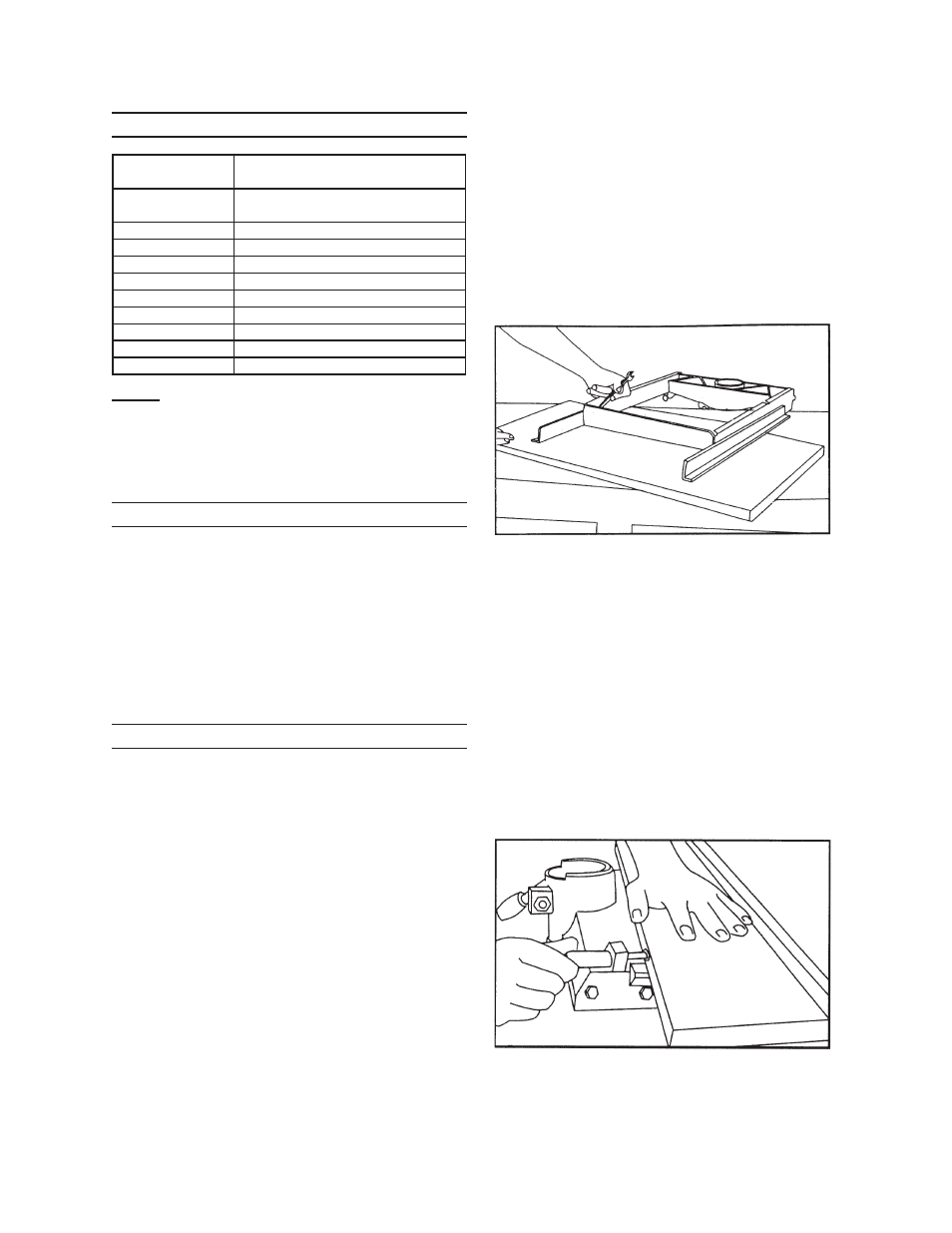

2. Turn the Base (152) assembly upside

down. Attach Table A (127) squarely

to the Base assembly using the four

cross-head Tapping Screws (165).

Attach the table stabilizer Stands to

3.

both sides of the Base using four Hex

Nuts (82), Washers (149), and Round

Head Bolts (148).

Place the Table and Base assem-

4.

bly on the workbench, right side up.

Secure to the workbench with nuts,

bolts, and washers (not supplied).

5. Position Table B (126) and Table C

(125), and the rip fence (guide) and