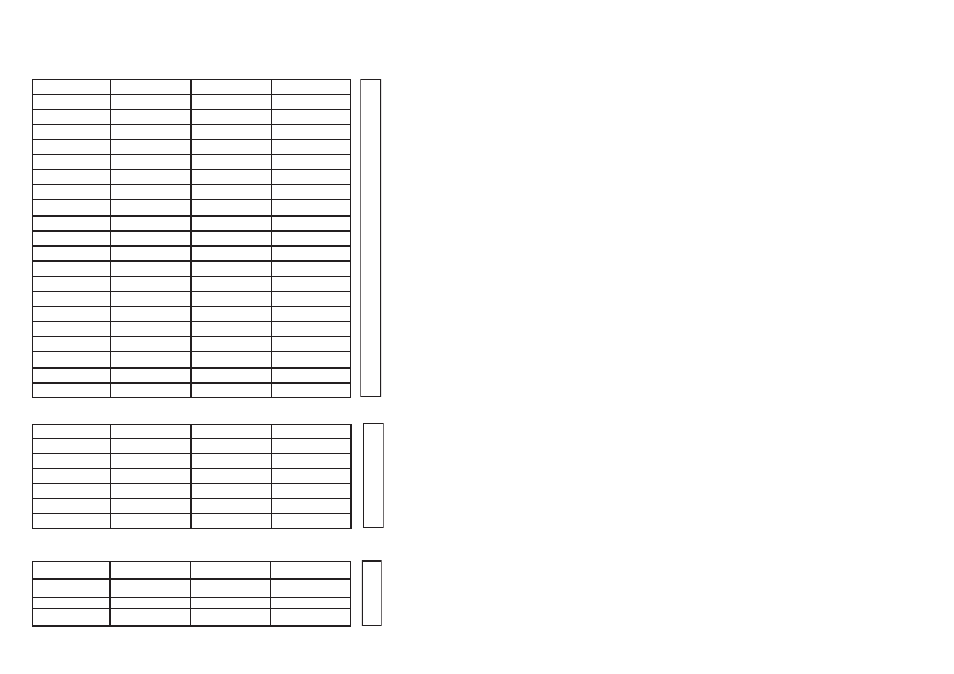

Chemical compatibility chart – Scilogex Unoverse Peristaltic Pump Dispense 9100 User Manual

Page 2

Page 9

13. FAQ

1.

Q. Why does the pump stalls or runs slower than expected when new

tubing is installed?

A. A new Santoprene tube is stiff when new so has to be shaped for some time

before it gains it’s elasticity. Run the pump in continuous mode for a total of

approx 5 minutes with the clamp lever half open to start with, gradually moving

the clamp lever to fully closed position.

2.

Q. What is the life of the tube?

A. The life of a peristaltic tube depends on many variants such as

speed, the reagent it is pumping and temperature. In general you should

expect approximately 800 hours operation from one tube.

3.

Q. Why does the displayed value sometime ‘jump’ in double

figures?

A. This happens when dispensing small volumes with the ID2.0mm

tubing. Following the calibration procedure the instrument’s

mathematical calculation divides the volume to be dispensed by the

number of pulses received from the motor’s encoder and stores this

value. If the volume per rotor rotation is relatively large, the ratio of

pulses to volume is coarse. In these circumstances the required volume

input does not divide into stored values, and therefore the calculator will

round up or down to the nearest whole figure. Whenever you use the

ID1.0mm tube, the dispensed volume per rotor rotation is small enough

to allow single μl per displayed digit.

4.

Q. Can I leave the unit switched ‘ON’ throughout the day?

A. Yes, you can. The dispenser requires very little energy when the

pump is not running so continuous power into the unit will not harm it.

5.

Q. Why can’t I set slower dispense speed ?

A. The motor’s speed is controlled via the voltage supply to the motor.

Too low voltage and the pump’s motor will stall, in particular when the

tubing is new and the resulting load on the motor is higher.

6.

Q. Can I dispense hot reagents using the dispenser?

A. Yes, the dispenser to works safely with media temperatures of up to

100°C. Be aware that the internal electronics could be damaged by any

ingress of fluids or steam vapours.

Acetaldehyde

Chloroacetic acid

Linseed Oil

Potassium salts

Acetic acid

Chronic acid

Magnesium salt

Silver salts

Acetic Anhydride

Chromium salts

Maleic acid

Soap solutions

Acrylonitrile

Copper salts

Manganese salts

Sodium salts

Aluminum Chloride

Ethylene glycol

Mercury salts

Sodium hydroxide

Aluminum sulfate

Ferric salts

Methanol

Sodium hypochlorite

Ammonia

Fluoborate salts

Natural gas

Stearic acid

Ammonium salts

Fluoboric acid

Nickel salts

Sulfur dioxide

Ammonium hydrox-

ide

Fluosilicic acid

Nitric acid-10%

Sulfuric acid, dil.

Amyl acetate

Formaldehyde

Nitroethane

Sulfurous acid

Antimony salts

Formamide

Nitrogen oxides

Tannic acid

Arsenic salts

Formic acid

Nitrous acid

Tanning extracts

Barium salts

Glucose

Oils, animal

Trisodium phosphate

Benzoic acid

Glycerins

Oils. mineral

Urea

Bleaching liquor

Hydrochloric acid

Oils. vegetable

Uric acid

Boric acid

Hydrocyanic acid

Oxalic acid

Water

Bromine

Hydrogen peroxide

Oxygen

Water (brine)

Butyric acid

Hydrogen sulfide

Phosphoric acid

Water (stoam)

Calcium salts

Iodine and solutions

Phthalic acid

Zinc salts

Carbon Dioxide

Lactic acid

Phosphoric acid

Chlorine (wet/dry)

Lead salts

Plating solutions

Acetates

Butane

Me Et Ketone

Skydrol 500-B4

Acetone

Butanol

Nitric acid-30%

Sulfuric acid-90%

Alcohols

Essential Oils

Nitrobenzene

Tetrahydrofuran

Amyl alcohol

Ethers

Oleic acid

Turpentine

Aniline

Ethanol

Phenol

Benzaldehyde

Furfural

Propanol

Benzyl alcohol

Lithium grease

Pyridine

Benzene

Cyclohexane

Kerosene

Nitric acid- 70%

Carbon tetrachloride

Ethyl chloride

Trichloroethylene

Perchloroethylene

Chlorobenzene

Freon

Lacquer

Toluene

Chloroform

Gasoline, unleaded

Naphtha

Xylene

Little

or n

o

effe

ct on S

a

topre

n

e

Sev

e

re

Moderat

e effe

ct

Chemical compatibility chart