Pro-Ject Audio Systems Pro-Ject RPM 10.1 Evolution User Manual

Page 5

© Audio Trade GmbH · Pro-Ject RPM 10.1 · Revision 2013.2.1

5

Adjusting the vertical tracking angle (vta)

Put a record and the record weight on the platter. When the needle is lowered into the record groove and the

tonearm is not resting on the lift arm, the tube of the tonearm should be parallel to the surface of the record.

If it is not loosen both allen screws in the tonearm base just enough to allow vertical movement of the arm

pillar without force and slide the arm up or down until it is parallel.

Carefully retighten the allen screws without applying excessive force (which would deform the arm pillar) –

finger tight is quite sufficient.

Adjusting the azimuth

The cartridge needle must be vertical in the record groove in order to trace the

groove wall modulations correctly.

A small screw at the bearing end of the arm allows incorrect azimuth to be

corrected if your needle is not mounted exactly perpendicular to the cartridge

body (which is often the case).

Slacken off the screw just enough to be able to revolve the arm tube without

applying force. Note! Do not remove the screw completely!

Screw

With the aid of a good magnifying glass adjust the needle until it is vertical in the groove (i.e. perpendicular

to the record's surface). Ideally this should correspond to the top surface of the cartridge body being parallel

to the record surface, but in practice this is often not the case.

When you are satisfied that the needle is vertical retighten the screw carefully.

Under no circumstances should the arm tube be adjusted with the needle still in the record groove!

Irreparable damage may be caused to the cantilever suspension! The arm must be lifted to make

each adjustment and lowered afterwards to check it.

Adjusting the magnetically supported bearing

The pressure put on the baring ball by the platter is reduced by an adjustable magnetic field. Your RPM 10.1 is

coming out of the box in a position "minimum magnetic force". In maximum position the platter virtually "flies"

on the magnetic field without any contact to the bearing ball.

The sonical differences are obvious, still the individual adjustment is determined by personal likings. By our own

experiences we learned, that a most natural musical performance is achieved by a just slight magnetic support

near position "minimum".

Turning the black square screw under the bearing (23) in clock direction is increasing the support, turning the

screw against clock direction reduces the support. A suitable screwdriver is added with the accessories.

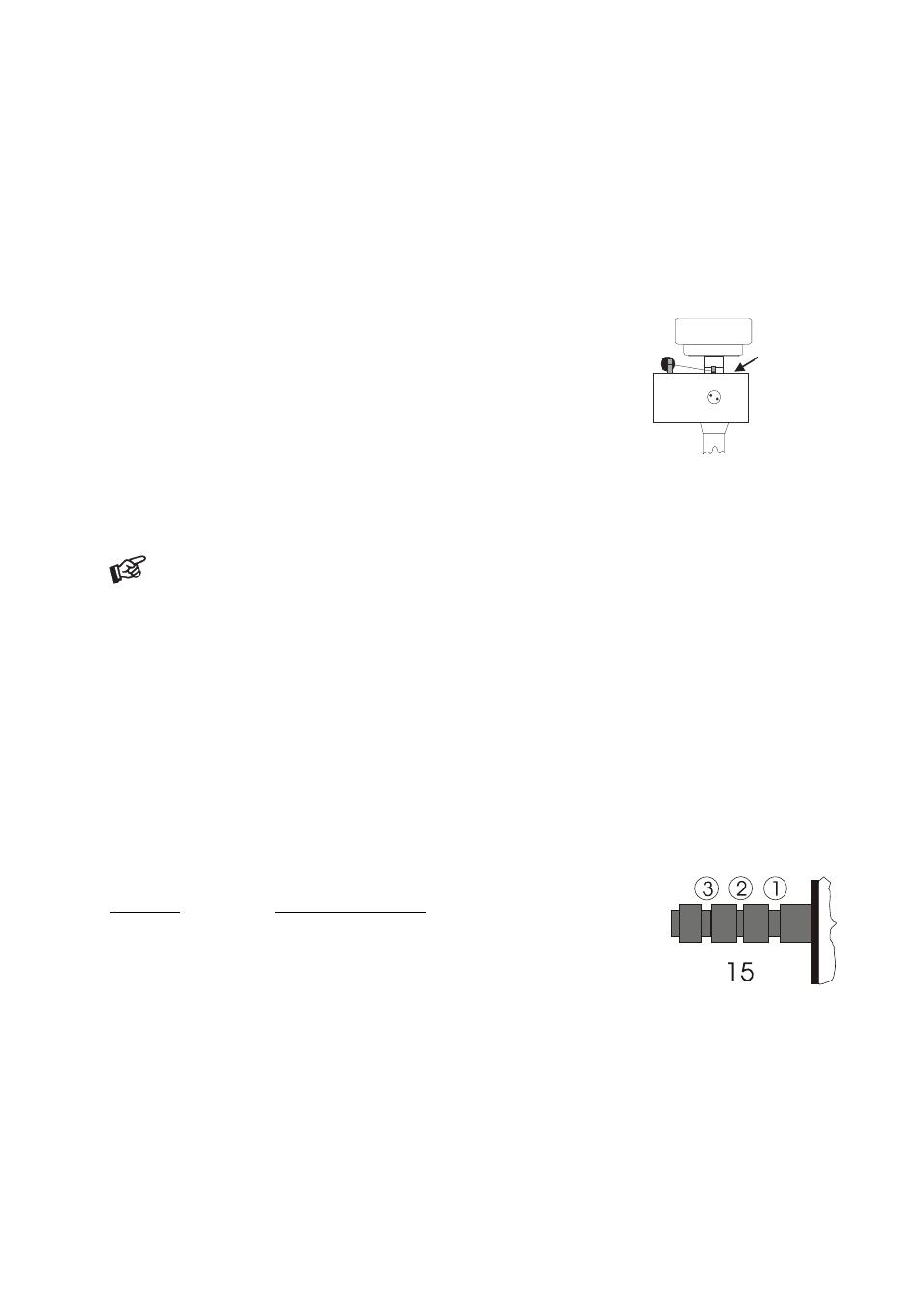

Anti-skating force adjustment

The anti-skating force must be adjusted corresponding to the downforce as follows:

Downforce

Groove in the stub (15)

10 - 14mN

1

st

from bearing rings

15 - 19mN

2

nd

" " "

20mN and bigger

3

rd

" " "

Hang the loop of the thread of the anti-skating weight in the groove of the anti-skating stub (15) corresponding

to the downforce applied to your cartridge and hang the thread in the groove of the wire support (17).

Mains power connection

The turntable is supplied with a power supply suitable for your country's mains supply. Check the label before

connecting to ensure compliance with the mains rating in your house.

Connect the low voltage plug from the power supply to the record player's motor unit (13) before connecting

the power supply to the mains.