A - air and oil circuits, Key fig. 4, Fig. 4 - air / oil circuit – Chicago Pneumatic CPVS 40 User Manual

Page 11

Chicago Pneumatic Compressors

62 305 258 65

01/2008

Page 11

Section 4 - Operation

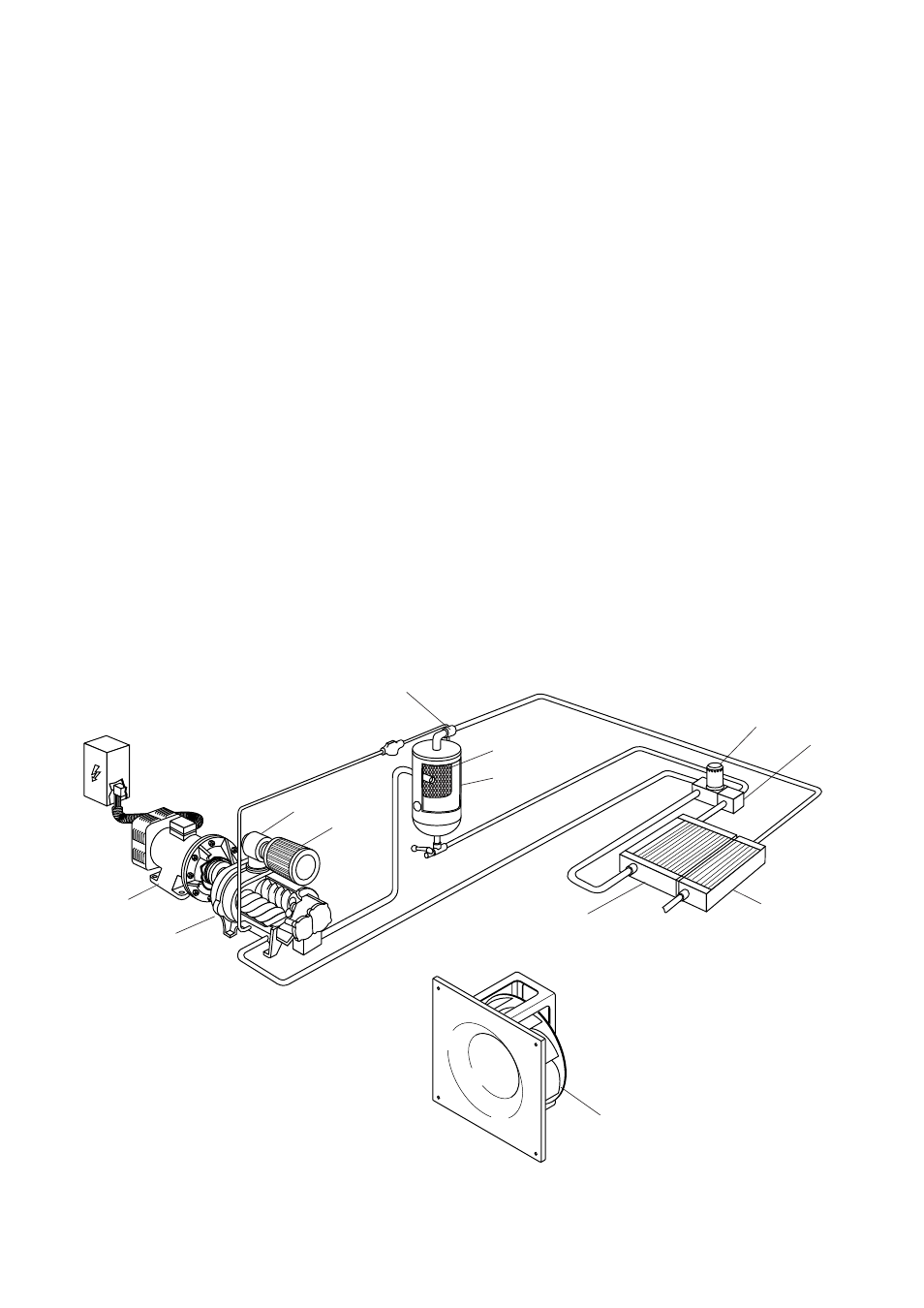

A - Air and oil circuits

1 - Air circuits (see Fig. 4)

The air is sucked into the compressor through a filter (rep. 23).

This air passes through the compression element where it is mixed

with oil injected during compression. Inside the oil tank, the

compressed air is pre-deoiled by shocks, then flows through the

oil separator (rep 49). It then passes through the mini pressure

valve (rep 34) forming a check valve, the aftercooler (rep 51A),

the condensate separator (in option), and lastly the outlet valve

(not supplied) to which the distribution pipe is connected.

2 - Oil circuit (see Fig. 4)

The oil, under discharge pressure, flows from the bottom of the tank

through the cooler (rep. 51H), the oil filter (rep. 26) which retains solid

impurities, and then into the compressor (rep. 20). At each cold start,

the thermostat valve (rep. 47) short circuits the oil radiator, thus enabling

the optimum operating temperature to be attained quickly. When it

leaves the compressor, the oil returns to the tank. Part of the oil remains

suspended in the air as mist. This mist passes through the oil separator.

(rep. 49). The remaining oil, which is separated by the last stage of the

oil separator, is drawn up by a dip tube and dispatched to the

compressor.

Key fig. 4

20

Compressor

21

Suction element

23

Air filter

26

Oil filter

34

Minimum pressure valve

41

Ventilator

47

Thermostat valve

49

Oil separator

51 A

Air cooler

51 H

Oil cooler

56

Main motor

57

Tank

Fig. 4 - Air / oil circuit

20

56

41

34

23

57

51A

51H

49

26

47

21