B series – Crown Equipment Power Lift Stackers B Series User Manual

Page 3

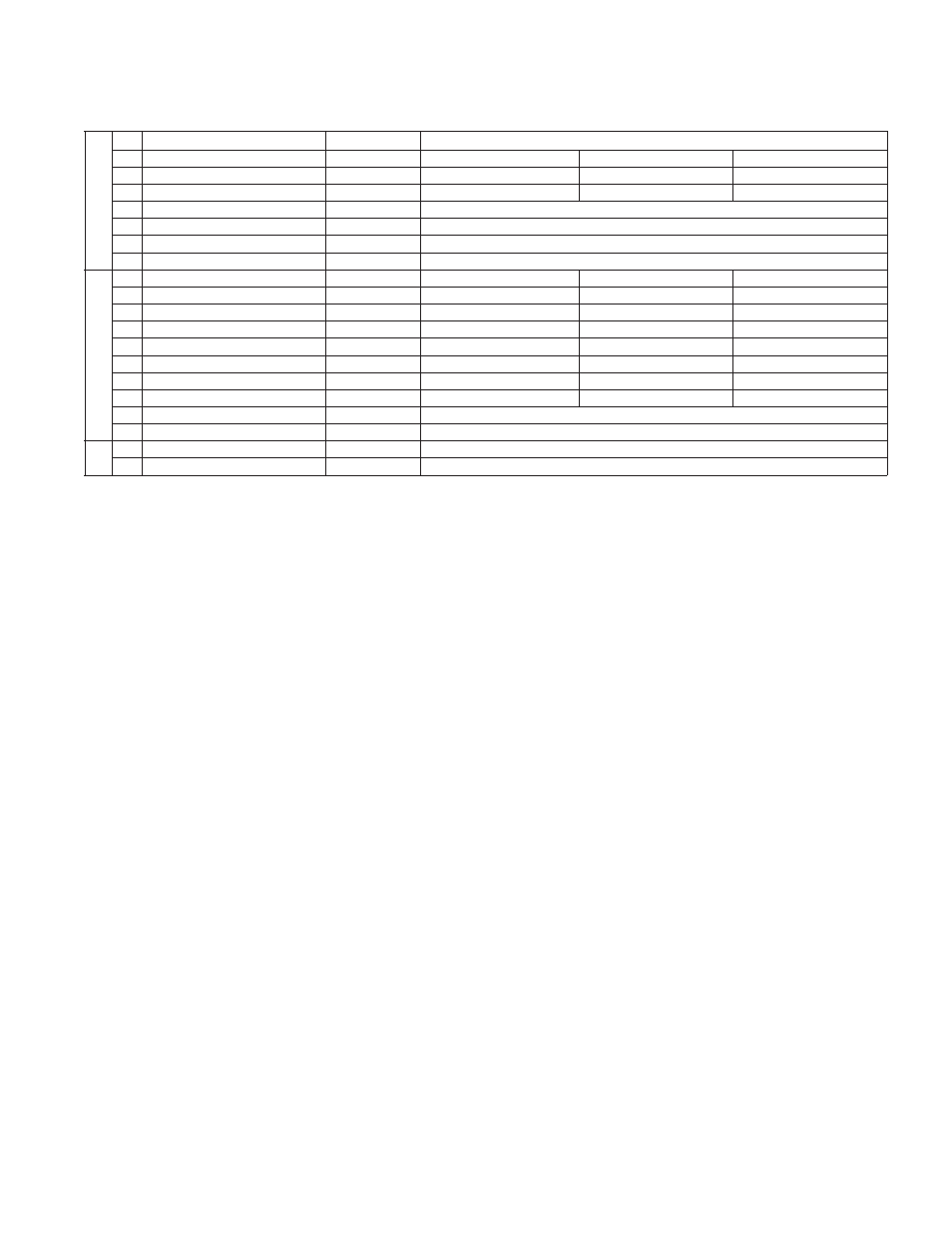

B Series

Specifications

1

Manufacturer

Crown Equipment Corporation

2

Model

20B

20BS

20BT

Mast Type

Single

Single

Telescopic

Load Handling Configuration

Fork Over

Straddle

Straddle

3

Power

Electric**

12-Volt Lift System

4

Operator Type

Walkie

5

Load Capacity*

Max

lb

2000

6

Load Center

in

24

7

Lifting Height

in

57

67

54

64

90

110

Free Lift

in

52.5

62.5

52.5

62.5

51

61

8

Collapsed Height

in

78.3

78.3

78.3

78.3

81.5

81.5

9

Extended Height

in

78.3

79

78.3

78.3

111

131

10

Head Length

in

17

19.12

21.5

11

Wheelbase

in

36.3

41.81

43.5

12

Net Weight with Batteries

lb

755

855

1295

13

Inside Straddle

in

18.12

26.5

32-50

Outside Straddle

in

6.3" + Inside Straddle Dimension

14

Fork Length

in

30 Standard, 36, 42 and 48 Available

15

Lifting Speeds

w/wo Load fpm

18/35

16

Lowering Speeds

w/wo Load fpm

38/22

General Information

Dimensions

* Attachments and longer load dimensions may result in derating of the capacity. Contact local dealer.

** Manually propelled for horizontal travel

B Series

Technical Information

Capacity

2000 lb at 24" load center.

Batteries

Two 6-volt, three cell 17 plate

lead acid batteries. Each battery

rated at 100 amp hours at 20

hour rate, and 87 amp hours at

six hour rate.

Charger

Built-in 110/130 volt silicon rectifier

type. Built-in ammeter shows

charging rate during charging

cycle. Other voltages available.

Standard Equipment

1. 12-volt fused electrical

system

2. Plexiglass safety shield

3. Dual floor locks

4. Emergency power disconnect

5. Batteries

6. Built-in 120-volt battery

charger

7. Adjustable outriggers (BT only)

Optional Equipment

1. Snap-on platform

2. Polyurethane load and

caster wheels

3. Load backrest

4. Key switch

5. Remote lift/lower control with

12' coil cord and push-button

station

6. Fifth-wheel steering

Chassis

Fabricated from steel plate

and bar stock completely shot-

blasted prior to finish coat. Base

plate formed from steel plate

and reinforced with protective

bumper skirt. Vertical guide mast

assembly welded as an integral

part of main chassis. Guide mast

channels on telescopic models

are a special, hot-rolled steel

section designed exclusively for

lift truck use.

Carriage Rollers

Alloy steel rollers contoured to

fit mast and equipped with

roller bearings.

Lift Chain

Two alloy steel leaf-type lift chains.

Outriggers

Formed from heavy-gauge steel

plate with end contoured around

load wheel. Outrigger and load

wheel axles are flush to prevent

pallet or skid damage.

Forks

1.5" thick x 3" wide forged-steel

forks with full upset heel standard

on all BS and BT models. Fixed,

formed 2.75" thick x 4.75"

wide steel forks welded to fork

carriage on B models.

Wheels and Tires

Standard equipment includes:

Steel caster wheels

5" dia x 1.88" face.

Steel load wheels 4" x 2" face.

All wheels equipped with roller

bearings.

Operator Controls

1. Raise/lower lever located

between chassis uprights.

Provides a fixed lifting speed

and variable speed lowering.

2. Safety power disconnect lever,

located next to raise/lower

control, shuts off all battery

power to truck.

3. Foot operated floor lock lever.

Pedal raises/lowers two

spring-loaded, flat-rubber

pads.

Hydraulic System

1. Heavy-duty motor, gear pump,

check valve, relief valve and

control valve

2. Pressure compensated flow

control valve to regulate

lowering speed.

3. Lift cylinders equipped with

polyurethane packings.

4. Drain line from lift cylinder

to reservoir.

5. Hydraulic fluid reservoir

equipped with breather-filter

to prevent foreign matter from

entering hydraulic system.

6. Overload valve set to bypass

fluid to reservoir when system

reaches maximum pressure.

Safety Shield

Clear, high-impact plexiglass to

help protect operator from chains

and cylinder.

Other Options

1. Audible travel alarm

2. Flashing lights

Safety considerations and

dangers associated with audible

travel alarms and flashing lights

include:

• Multiple alarms and/or lights

can cause confusion.

• Workers ignore the alarms

and/or lights after day-in and

day-out exposure.

• Operator may transfer the

responsibility for “looking out”

to the pedestrians.

• Annoys operators and

pedestrians.

Dimensions and performance

data given may vary due to

manufacturing tolerances.

Performance is based on an

average size vehicle and is

affected by weight, condition of

truck, how it is equipped and the

conditions of the operating area.

Crown products and specifica-

tions are subject to change

without notice.