Notice maintenance, Installation, Operation – Campbell Hausfeld PA207802 User Manual

Page 2

11 Sp

Filtro • Regulador de Presión • Lubricador

Modelo PA207802

Para ordenar repuestos, sírvase llamar al concesionario

más cercano a su domicilio

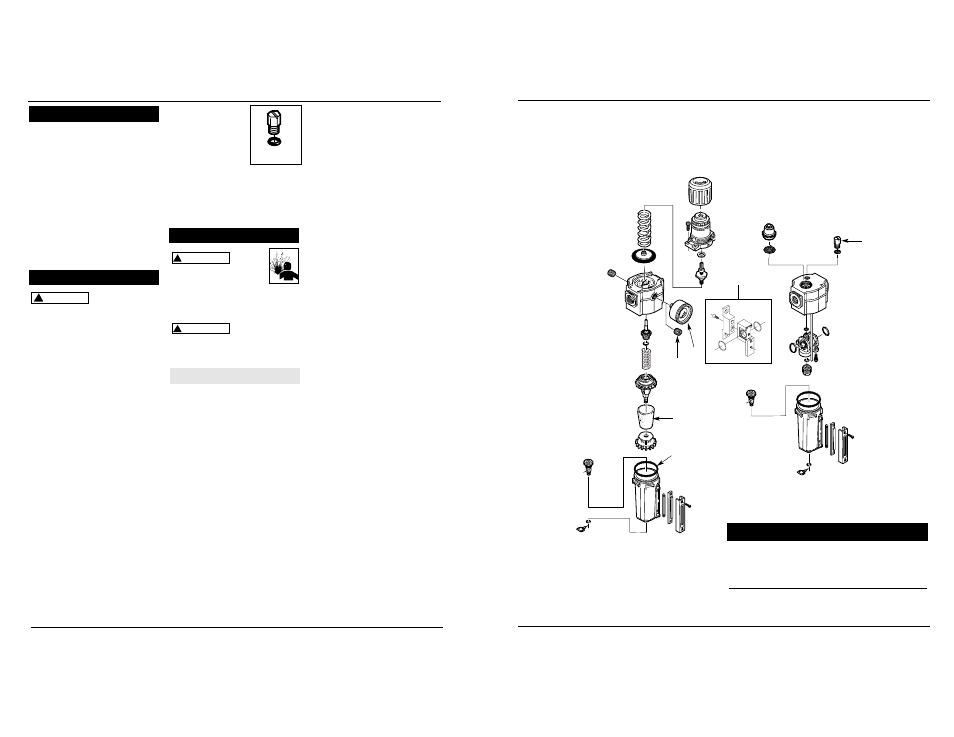

Figura 2

Lista de Repuestos

1

Medidor

SV899600AV

1

2

Tapón NPT de 1/4”

ST022500AV

1

3

Elemento del filtro

●, ■

1

4

Aro tórico del envase

■

1

5

Soporte modular

SX129700AV

1

■

Kit del elemento del filtro

SX129100AV

1

●

Elementos de repuesto del filtro

PA116510AV

2

No. de

Ref.

Descripción

Repuesto Ctd.

Puede escribirnos a:

The Campbell Group

Attn: Parts Department

100 Production Drive

Harrison, OH 45030 U.S.A.

Sirvase darnos la siguiente información:

- Número del modelo

- Número de Serie o código con fecha (de haberlo)

- Descripción y número del repuesto según la lista

de repuestos

7. The lubricator can

be refilled while

the system is under

pressure. Slowly

remove relief plug

to allow relief of

air pressure (See

Figure 2). After

the relief plug has been removed,

the bowl can also be removed. Pour

oil into the bowl and replace.

Replace relief plug before

resuming operation. Do NOT

replace the relief plug until the

bowl is securely locked in place.

Release all pressure before

attempting to install, service,

relocate or perform any

maintenance on the air system.

Personal injury and/or property

damage could occur.

Always depress-

urize the unit

before removing the bowl. Personal

injury and/or property damage could

occur. If bowl is difficult to remove, it

may be under pressure.

1. Inspect and replace cracked,

damaged or deteriorated seals and

bowls. Wipe bowls with a soft, dry

cloth to clean.

2. Replace or clean filter element

periodically. Remove the filter

element and tap filter on a hard

surface or use an air gun to blow

out residual dirt.

3. Drain bowls at least once per work

shift. To avoid spray or splatter,

cover bottom of filter with a cloth

and turn the manual drain.

4. Before placing the unit in service,

make sure the bowl is reinstalled

and securely locked in place.

!

WARNING

!

WARNING

Technical Service

For information regarding the

operation or repair of this product,

please call 1-800-543-6400. If you are

calling from Ohio or outside the

continental United States, Please call

1-513-367-1182.

4. The configuration of the units can

be changed by removing the

modular bracket. To do this, first

loosen the center screw using a

5/32” (4mm) allen wrench. Slide the

two units out of the bracket and

replace them in the desired

direction. The air flow direction

arrows must both point in the

direction of the air flow. The

filter/regulator unit must be

placed before the lubricator.

5. Install the unit with the same pipe

size as the piping in use. Avoid

using unnecessary fittings,

couplings, etc., that restrict airflow.

6. Connect the air supply to the inlet

port.

Ensure the regu-

lator adjusting

knob is unlocked when adjusting

pressure. The regulator will be

damaged if the knob is turned in the

locked position.

1. Fill the lubricator bowl with

Campbell Hausfeld Oil (ST1270) or

clean, non detergent SAE 10 oil. Do

not fill past the Max Fill arrow on

the label.

2. Before pressurizing system, make

certain the bowls are securely

locked in place by pushing the

bowls into filter body and lubricator

body and turning clockwise to lock.

3. Unlock the regulator adjusting

knob by pulling knob away from

the regulator.

4. Turn the regulator adjusting knob

counterclockwise until no load is on

the regulating spring.

5. Turn on the air pressure supply and

turn the adjusting knob clockwise

until the desired outlet pressure is

reached. Push the regulator

adjusting knob toward the

regulator to lock in desired

pressure.

6. The oil flow is controlled by the

sight dome adjustment screw. Turn

counter-clockwise for more or

clockwise for less oil delivery. The

oil delivery rate automatically

adjusts with changes in air flow.

!

NOTICE

Maintenance

2

Filter • Pressure Regulator • Lubricator

Model PA207802

Installation

(Continued)

Operation

FILTER

1

2

3

4

5

Tapón de alivio

Relief Plug