Humboldt H-2911 — H-2919 Compressometers / Extensometers User Manual

Page 4

8 Remove the two spacer rods

9 Remove the three metal blocks from under the lower ring.

10 Zero the axial strain dial indicator with the stem close to the fully extended position.

Zeroing can be done (I) by rotating the dial face after loosening the lock screw on the

upper right hand side of the dial indicator or (2) by adjustment of the contact post

that fits into the lower lock ring.

11 Zero the diametrical strain dial indicator with its stem close to the fully pushed-in

position. (The stem is going to extend by the diametrical deformation of the

specimen). Zeroing of the dial can be done by rotating the dial face or by

adjusting the contact point.

Calculation

1 To Calculate the modulus of elasticity, to the nearest 50,000 psi (344.74 MPA)

as follows:

E = (S

2

- S

1

) / (

e

2

- 0.000050)Where:

E = chord modulus of elasticity, psi

S2 = stress corresponding to 40 percent of ultimate load or corresponding to

appropriate strain value from Table 1 (below), psi

SI = stress corresponding to a longitudinal strain, e

1

, of 50 millionths, psi

e

2

= longitudinal strain produced by stress S2.

2 To Calculate the poison's ratio, to the nearest 0.01 as follows:

m= (e

t2

- e

t2

) / (e

2

- 0.000050)

Where:

e

t2

= transverse strain at midheight of the specimen produced by stress S2.

e

t1

= transverse strain at midheight of the specimen produced by stress S1.

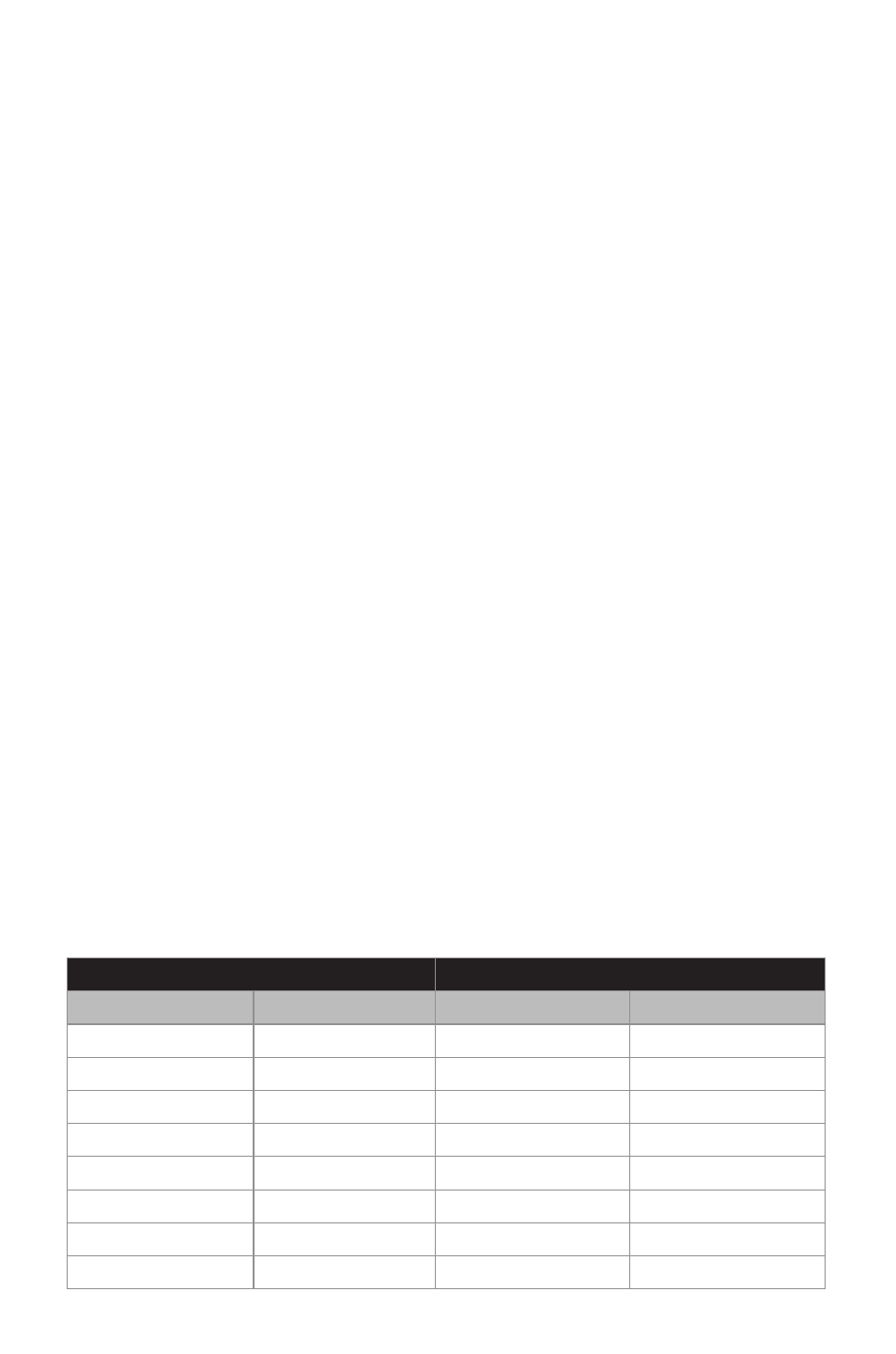

Unit Weight @ Time of Test

Strain @ Age Indicated, Max. Millionths

lb/ft

3

CK/M

3

7 Days or More

Less Than 7 Days

205

3280 and Over

300

200

165 to 204

2640 to 3264

375

250

135 to 164

2160 to 2624

450

300

115 to 134

1840 to 2144

525

350

105 to 114

1680 to 1824

600

400

95 to 104

1520 to 1664

675

450

85 to 94

1360 to 1504

750

500

75 to 84

1200 to 134

825

550

Table 1: Maximum Strain Values