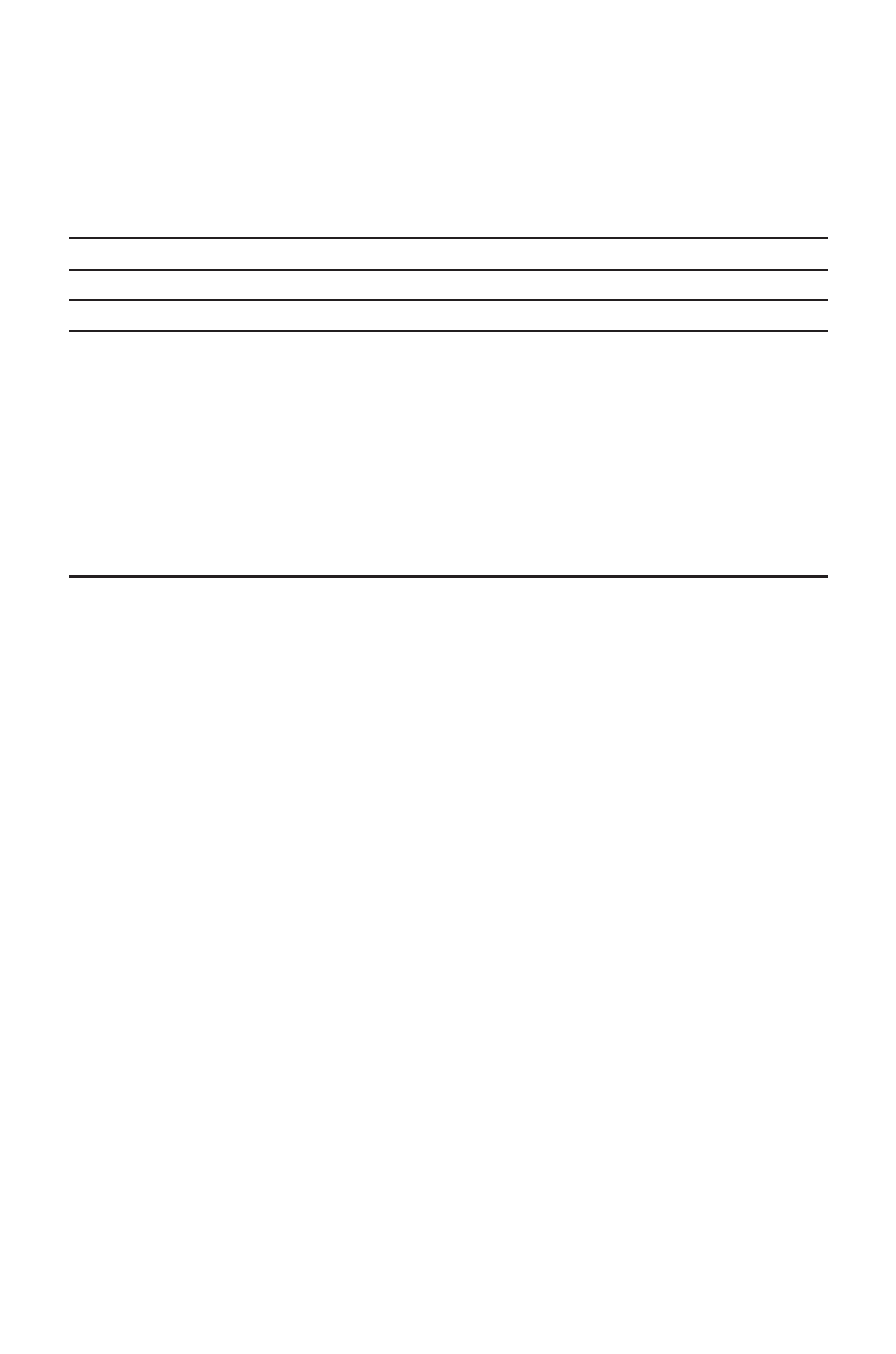

Table 1: grading of test samples, Calculation, Maintenance – Humboldt H-3860A Los Angeles Abrasion Machine User Manual

Page 4: Weight of indicated sizes, g, Ab c d

Test Sample

The test sample shall consist of clean aggregate that has been dried in an oven at

105°C to 110°C (221°F to 230°F) substantially to constant weight and shall conform to

a grading shown in Table 1. The grading used shall be the most nearly representing the

aggregate furnished for the work.

TABLE 1: Grading of Test Samples

Sieve Size (Square Openings)

Weight of Indicated Sizes, g

Passing

Retained On

Grading

A

B

C

D

37.5 mm (1 ½")

25.0 mm (1.0")

1 250 ± 25

...

...

...

25.0 mm (1")

19.0 mm (3/4")

1 250 ± 25

...

...

...

19.0 mm (3/4")

12.5 mm (1/2")

1 250 ± 10

2 500 ± 10

...

...

12.5 mm (1/2")

9.5 mm (3/8")

1 250 ± 10

2 500 ± 10

...

...

9.5 mm (3/8")

6.3 mm (1/4")

...

...

2 500 ± 10

...

6.3 mm (1/4")

4.75 mm (No. 4)

...

...

2 500 ± 10

...

4.75 mm (No. 4)

2.36 mm (No. 8)

...

...

...

5 000 ± 10

Total

5 000 ± 10

5 000 ± 10

5 000 ± 10

5 000 ± 10

Test Procedure

Place the test sample and the abrasive charge in the Los Angeles Abrasion Testing

Machine and rotate the machine at a speed of 30 to 33 rpm for 500 revolutions. The

machine shall be so driven and so counter balanced as to maintain a substantially

uniform peripheral speed. After the prescribed number of revolutions, discharge the

material from the machine and make a preliminary separation of the sample on a sieve

coarser than the No. 12 (1.70mm). Sieve the finer portion to a No. 12 sieve in a manner

conforming to section 5.2 of ASTM Method C136. Test for sieve or screen analysis of

fine and coarse aggregates. Wash the material coarser than the No. 12 sieve, oven dry

at 221°F to 230°F (105°C to 110°C) to substantially constant weight and weigh to the

nearest 1-G.

Calculation

The difference between the original weight and the final weight of the test sample shall

be expressed as a percentage of the original weight of the test sample. This value shall

be reported as the percentage of wear.

Maintenance

Keep the assembly as clean as possible.

Lubricate necessary parts regularly. Use heavy transmission oil-40 weight, for the speed

reducer (AGMA lubricant class 8 COMP). Some examples are as follows:

Oil Recommended for H-3860 Los Angeles Abrasion Machine:

•

Gulf Oil

Senate 680

•

Shell Oil

Omala 680

•

Texaco

Honor 680

•

Mobil

Extra Helica Super Cylinder Oil