Humboldt H-1684 Flakiness Gauge for Classification of Aggregate User Manual

Page 2

Introduction

This method is based on the classification of aggregate particles as flaky when

they have a thickness (smallest dimension) of less than 0.6 of their nominal

size, this size being taken as the mean of the limiting sieve apertures used for

determining the size fraction in which the particle occurs. The flakiness Index of

an aggregate sample is found by separating the flaky particles and expressing

their mass as a percentage of the mass of the sample tested. The test is not

applicable to material passing a 6.30 mm BS test sieve or retained on a

63.0 mm BS test sieve.

Apparatus

The following apparatus is required.

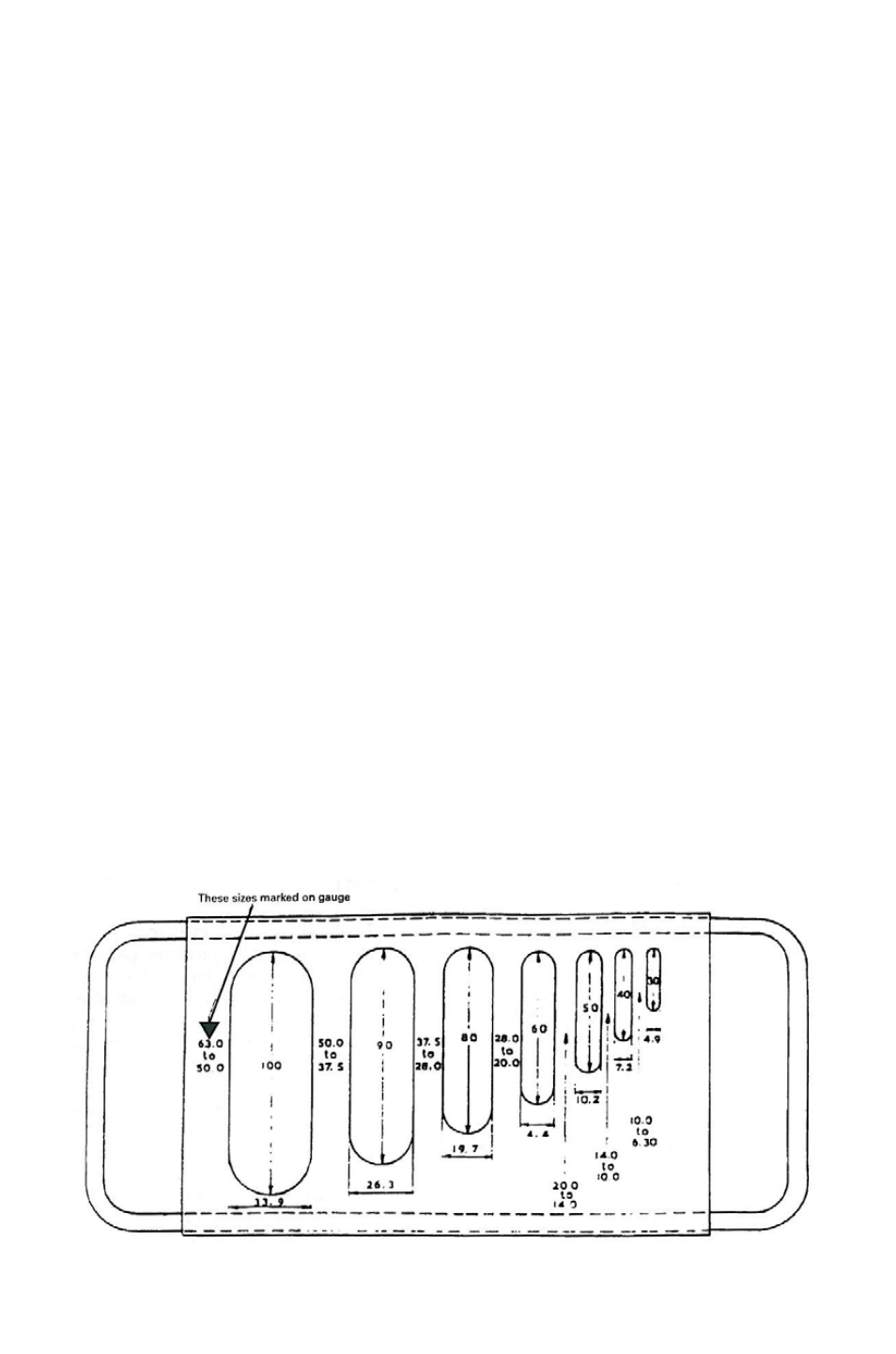

1. A metal thickness gauge of the pattern shown in Figure 5 or special

sieves having elongated apertures. The width of the apertures and the

thickness of the sheet used in the gauge or sieve shall be as specified

in Figure 1.

2. BS test sieves as shown in Table 9 as appropriate.

3. A balance accurate to 0.5% of mass of the test sample.

C. Sample for test:

The sample for this test shall be taken in accordance with BS 812. It shall

comply with the appropriate minimum mass, for sieve analysis with due

allowance for 63.0 mm BS test sieve and passing a 6.30 mm BS test sieve.

The sample shall be taken from the laboratory sample by quartering or by

means of a sample divider. Before testing it shall be brought to a dry

condition by standard methods.

D. Procedure:

Carry out a sieve analysis using the sieves given in Table 1.

Figure 1— Thickness Gauge (Flakiness Index) indicating sizes of openings.