Calibration overview, Calibrate with drill raised, Calibrate for 1§10th acre or hectare – Great Plains 3P806NT Material Rate User Manual

Page 4: Calibration crank storage, Using calibration crank, Check affected boxes, Calibration crank storage using calibration crank

2

3P806NT

Great Plains Manufacturing, Inc.

151-143B

2011-10-21

Calibration Overview

Detailed calibration steps vary with each box, see:

“Main/Dual Box Seed Rate Calibration” on page 6,

“Fertilizer Rate Calibration” on page 31,

“Native Grass Rate Calibration” on page 17, and

“Small Seeds Rate Calibration” on page 24,

Some general information applies to all boxes, and is not

repeated in those pages referenced above.

Calibrate with Drill Raised

Perform the calibration with the drill hitched and raised.

Install lift-assist cylinder lock(s). Calibration with the drill

lowered is not recommended, as the drive tires in ground

contact prevent drive operation.

Calibrate for

1

⁄

10

th

Acre or Hectare

The number of revolutions per area is:

Crank counts below 10 are not recommended. Sample

sizes may be too low, and fractional crank turns

introduce more error.

Calibration Crank Storage

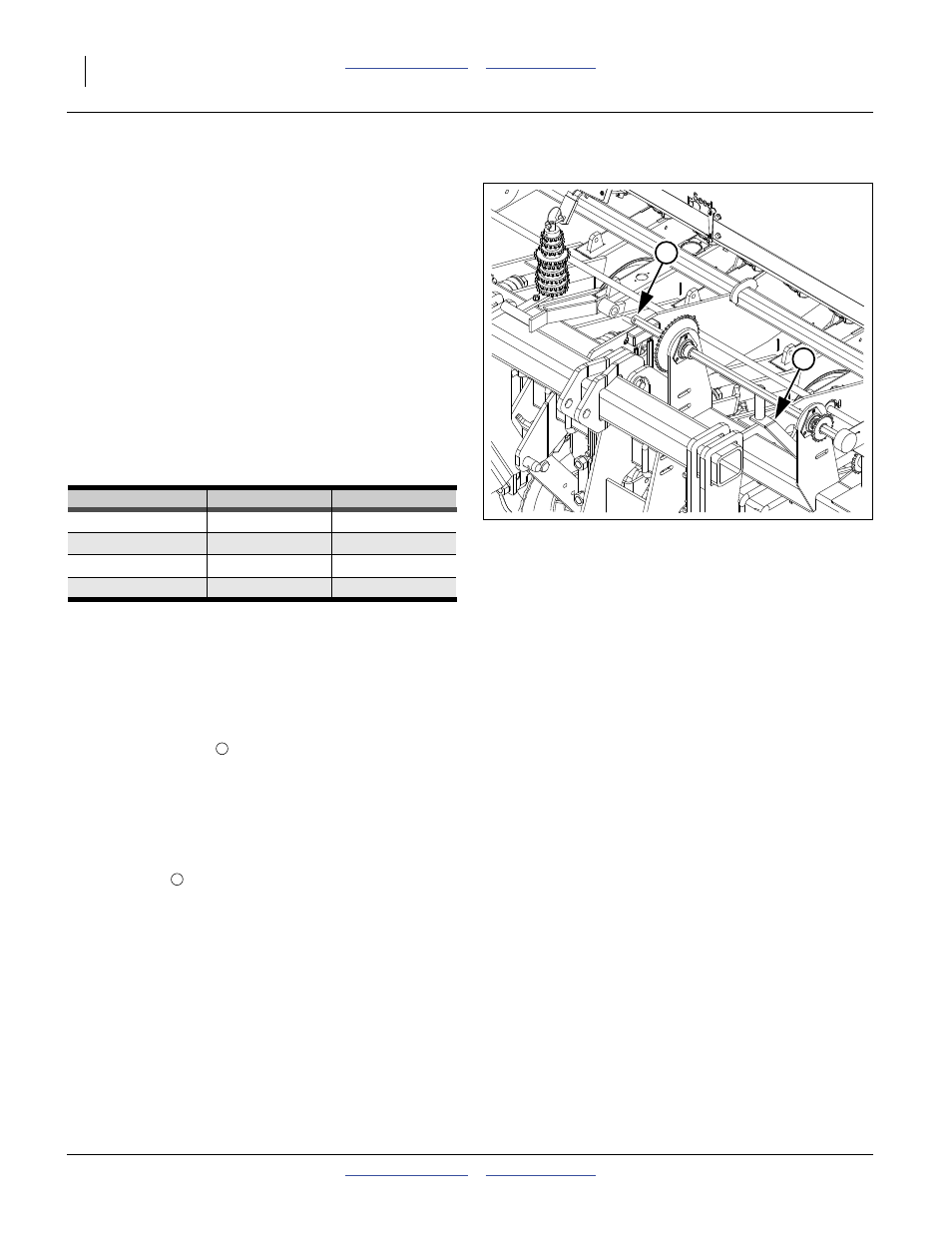

Refer to Figure 2

The calibration crank

is found at the top front frame,

left of center, pinned to a stob on a 3-point weldment.

Note: The retaining pin at the stob can also secure the

crank to the jackshaft.

Using Calibration Crank

Place the hex socket of the crank on the right end of the

main jackshaft

Operate the crank clockwise

A wide range of cranking speeds produce accurate

calibrations. For reference, at 6 mph (10 kph) field speed,

jackshaft rpm is 65 (about 1 revolution per second).

Check Affected Boxes

Empty any boxes not being calibrated or remove a drive

chain to prevent undesired meter operation. Alternatively,

set rate handles to zero.

Figure 2

Calibration Crank

28410

2

1

revolutions for

Crank

Tire

Full Acre

656

1170

65.6

117

Full Hectare

1622

2890

162

289

32341

1/10

th

Acre

1/10

th

Hectare