Setting drive type, Changing drive type – Great Plains 3S-5000HDF Material Rate User Manual

Page 5

Great Plains Manufacturing, Inc.

Setting Main Box Seed Rate

3

2012-06-04

195-325B

Setting Drive Type

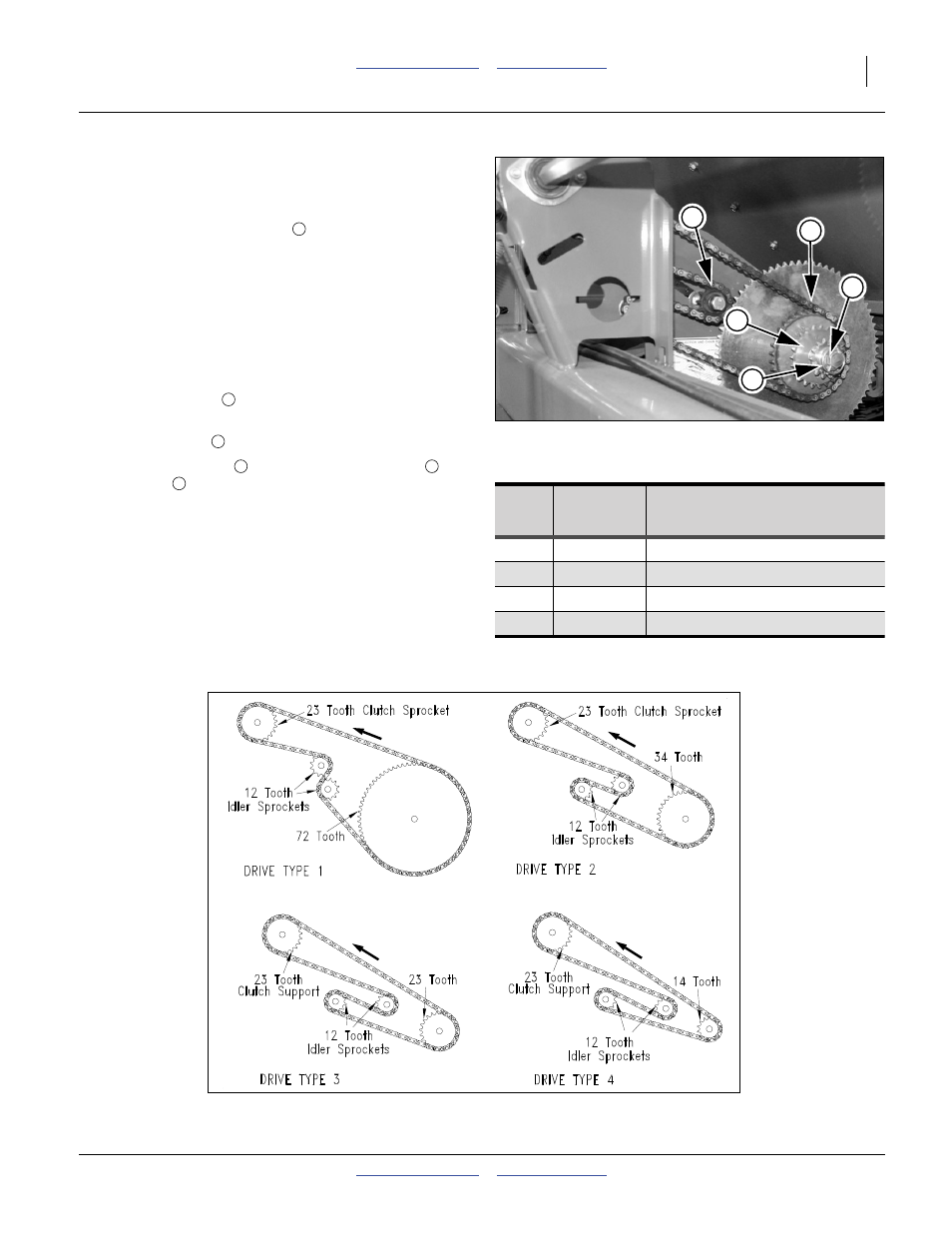

Refer to Figure 1

Drive Type is determined by the size (tooth count) of a

sprocket on the seed jackshaft

of each drill section. If

changed, the sprocket must be set identically on each

drill section (3 locations).

For correct Drive Type, refer to seed-rate charts

beginning on page 8. The charts list Drive Types as 1, 2,

3 or 4. Each Drive Type corresponds to a specific sized

sprocket, per the table at right, and Figure 2 below.

Changing Drive Type

1.

Loosen top idler

and slide idler well forward,

particularly if changing to Drive Type 1.

2.

Lift drive chain

off sprocket currently in use.

3.

Remove lynch pin

and rearrange sprockets

on

jackshaft

. Sprocket corresponding to the required

Drive Type is second innermost. Make sure all four

sprockets are accounted for when remounting them

on the shaft.

4.

Remount drive chain on the second innermost (Drive

Type) sprocket.

5.

Re-engage top idler and secure. Allow

1

⁄

2

inch

(13 mm) slack in longest (top) span of chain.

6.

Set the same Drive Type on all three drill sections.

Figure 1

Drive Type 2 Configured

26481

Drive

Type

Sprocket

Relative Speed

1

72 Tooth

Slowest

2

34 Tooth

2.12 times faster than Type 1

3

23 Tooth

3.13 times faster than Type 1

4

14 Tooth

5.14 times faster than Type 1

1

4

2

3

5

Figure 2

Drive Type Chain Routing

18839

- 3S-5000HD Material Rate 3S-5000F Material Rate 3S-5000 Material Rate 3S-4000HDF Material Rate 3S-4000HD Material Rate 3S-4000F Material Rate 3S-4000 Material Rate 3S-3000HDF Material Rate 3S-3000HD Material Rate 3S-3000F Material Rate 3S-3000 Material Rate 2S-2600HDF Material Rate 2S-2600HD Material Rate 2S-2600F Material Rate 2S-2600 Material Rate