8 pro-lift trip-reset tine hydraulics – Great Plains SLD350 Operator Manual User Manual

Page 32

32 Simba SLD

602-262M-ENG

2013-07-25

5.8 Pro-Lift Trip-Reset

Tine Hydraulics

The circuit allows for the tines to be

pressurised down into work, whereupon a

relief valve limits this applied tractor down

pressure to a value less than the main system

accumulator (80b x 2 litre). This allows tines

to trip in work, the oil being absorbed by

the main accumulator. A secondary (rod

side) accumulator ensures this side of the

cylinder is maintained full of oil to minimise

cavitation and seal damage. A pre charge

valve restricts return rod side oil flow to the

tractor as the tines are pressurised down

to ensure this secondary circuit is charged.

In operation, oil is locked in the cylinder

circuit at a pressure determined by the relief

valves 90-120 bar full bore side and 0-20 bar

rod side. This occurs at all times, even with

the circuit in float at the tractor, provided the

tines are fully down. For extremely stony

conditions, adjust the valve to read 90 bar

on the gauge as the tines are pressured

down. For heavy soils with little stone

where compaction is present it is possible

to increase this pressure to 120 bar.

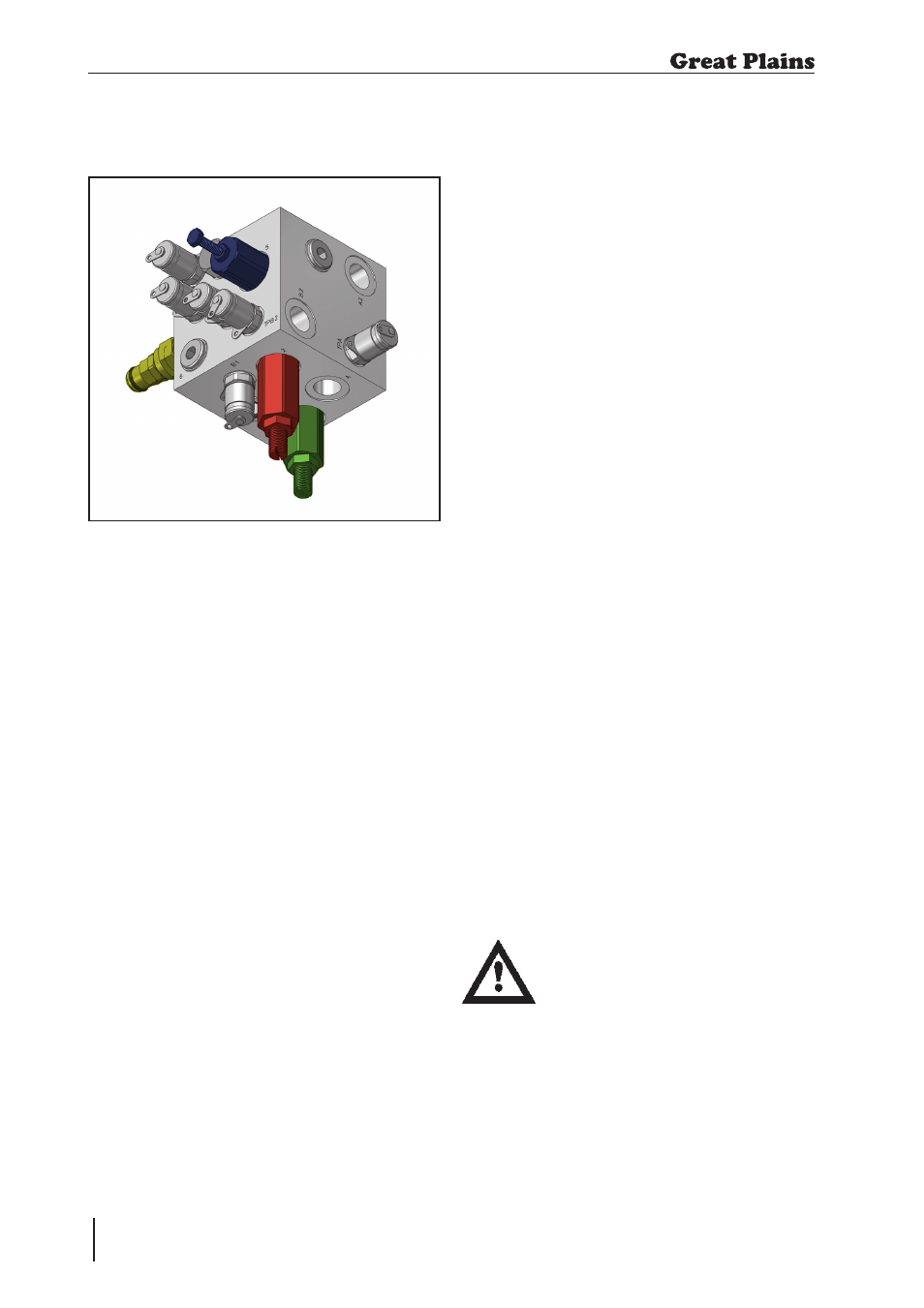

Fig. 5.05: Pro-Lift Tine Hydraulic Manifold

5. Servicing and Maintenance

If the tine circuit should need setting the

following procedure should be followed (an

assistant will be required):

1. Raise machine, to ensure tines are fully

clear of the ground at depth.

2. Adjust relief valve (

marked 1 /

coloured green) clockwise fully. Turn

anticlockwise one full turn.

3. Adjust flow control (

marked 5 /

coloured blue) fully clockwise, then

anti-clockwise 4 turns.

4. Adjust accumulator relief valve

(

m a r k e d 2 / c o l o u r e d r e d )

anticlockwise fully. Turning clockwise

now will increase the pressure on the

top gauge.

5. Remove cap from sequence valve and

remove the anti-tamper pin. Loosen

anticlockwise fully and then tighten

clockwise until slight resistance is felt.

6. Pressure tines down and further adjust

sequence valve (

marked 3 / coloured

yellow) until bottom gauge reads

10-20 bar.Lock with lock nut and refit

anti-tamper pin and cap.

7. Continue to hold pressure in tine

circuit and set accumulator relief (

2) to

between 90 and 150 bar (see section

5.9.1) as tines are lowered.

If tines do not relieve under severe

overload, this valve should be

reduced (anti-clockwise) until this

occurs in work, otherwise damage

may occur.

8. Put main circuit in float, check that

pressure is maintained.