7 operation – Great Plains P17398E Operator Manual User Manual

Page 21

21

Flatliner 500

Operating Instructions

4. Adjustment / Operation

4.7 Operation

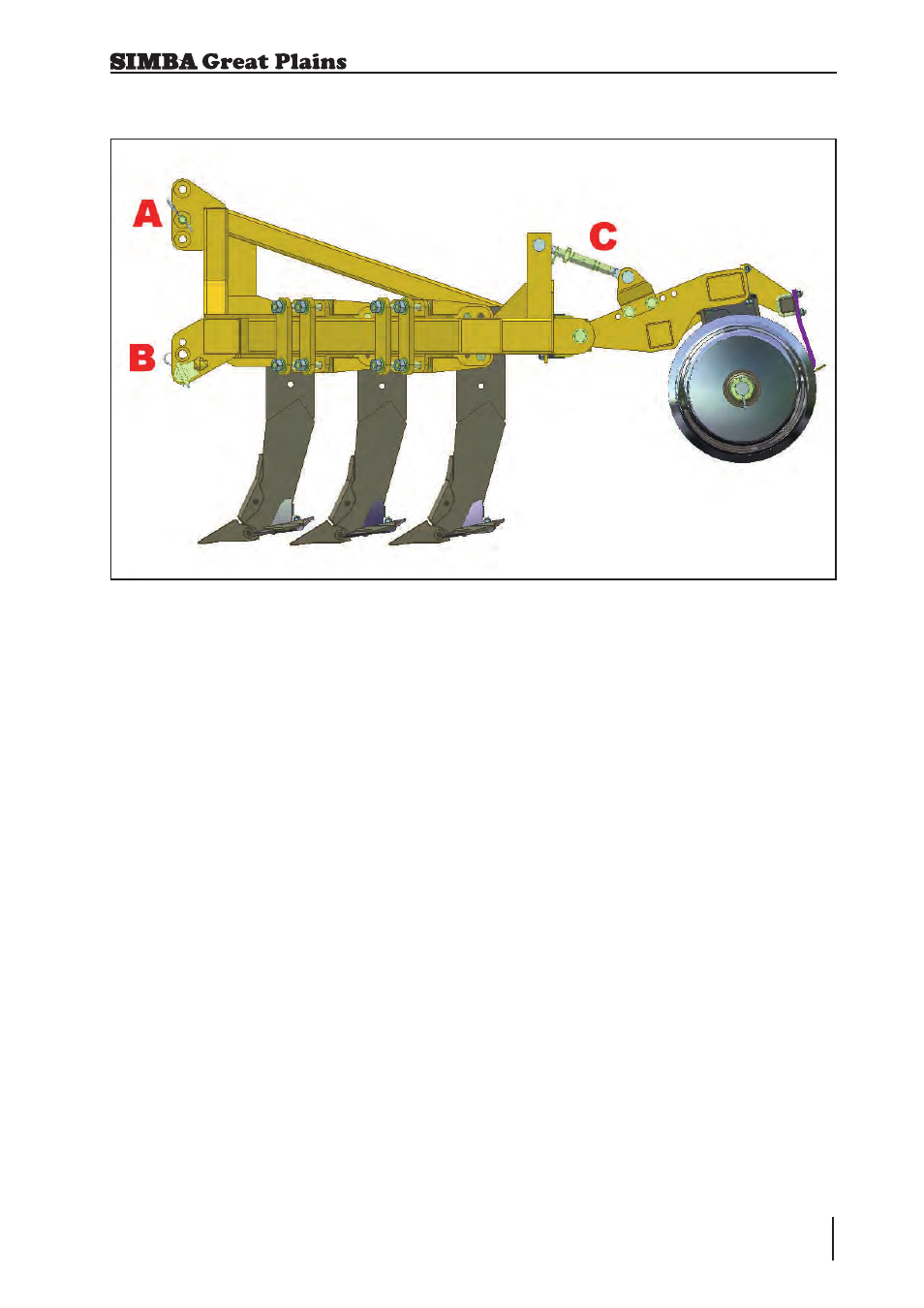

With the Flatliner 500 mounted on the tractor

three-point linkage, lower the machine until

the foot of the leading tine is resting on the

ground. The trailing tines should be 50 to

125mm clear of the ground, depending on

the width of the implement and what the

desired operating depth is to be. Set the

trailing tines by adjusting the length of the

toplink (A).

Once in work the operating depth of the

machine has to be controlled by the roll unit

or else it will attempt to go deeper. The roll

unit is set using the toplink (C).

The roll unit serves two functions; it conserves

soil moisture, breaking up any clods left by

the tines and limits the operating depth of the

machine. The pressure that may be exerted

upon the clods by the roll is limited by the

weight of the implement and the downward

tine thrust. This downward thrust can be

increased by fitting wider wings, or slightly

increasing the angle of the points and wings

(shortening the toplink - A), and by minimising

any draft control setting on the tractor. This

is the first area to be investigated, if more

crumbler pressure should be required. Draft

control can also inhibit initial penetration

if the implement is lowered too quickly on

the move into work. The rapid increase in

draft is sensed by the tractor, which then

inhibits further penetration. The solution is

to gradually lead the implement into work,

thereby not imposing a rapid increase in

pulling force.

In most cases where a significant roll

pressure is required it is advisable to

eliminate draft control if possible.

The Flatliner 500 must run reasonably level

or slightly nose down to achieve consistant

results across its width and any increase in

downward thrust will significantly increase

the pull required.

Fig. 4.06: Flatliner Operation