5 dd light roll, 2 bearing seals, 6 preparation for storage – Great Plains DTX300 P16315 User Manual

Page 27: Servicing and maintenance

27

DTX 300

Operating Instructions

5. Servicing and Maintenance

5.5 DD Light Roll

The spacers and rings on the DD Light Roll

are held under tension by the end plates at

the outer ends of the roll tube.

Specialist equipment is required

for the disassembly of DD Light

rollers. Please consult your dealer

under any circumstances that

require disassembly of these

rollers.

Maintenance of these rollers is limited to

yearly/end of season greasing of the bearings

and regular inspection to ensure the

assemblies are tight, and scrapers are

correctly set.

The scraper is intended to clear dirt

from blocking between adjacent DD

rings. If adjustment to the scrapers

is required ensure that the scraper

cannot contact the spacer even

under load. Regularly inspect the

spacers for signs of wear and adjust

any scrapers to ensure no contact

can be made.

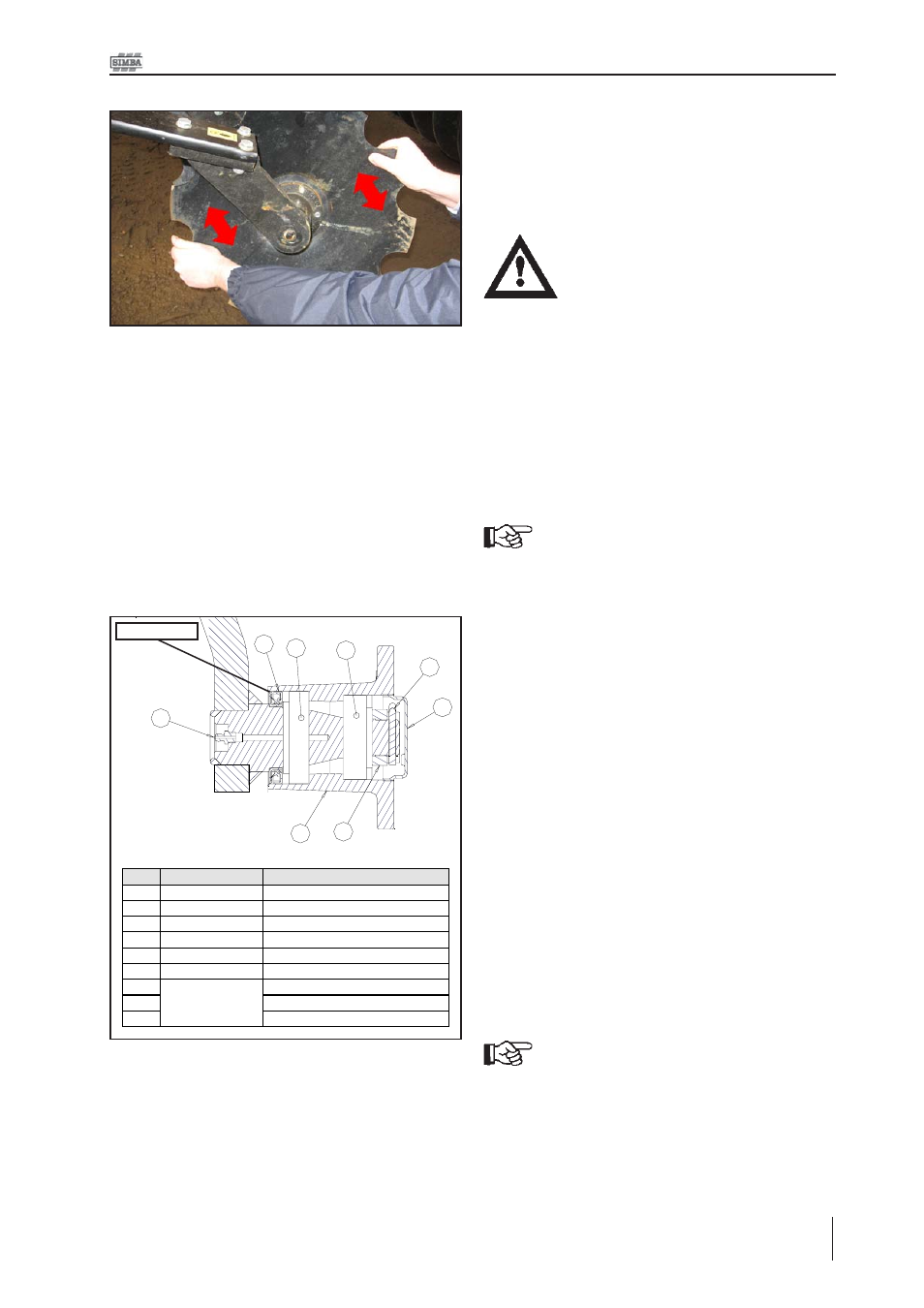

5.4.2 Bearing Seals

It is important when replacing the labyrinth

type bearing seals in disc hubs that the seal

is fitted the right way round. The chamfered

lip side should be at the outside of the bearing

housing, nearest the disc arm (see Fig. 5.02).

This chamfered lip prevents dirt ingress into

the housing and also allows grease to be

flushed though when greasing.

Chamfered Seal

Fig. 5.02: Correct Seal Orientation

3

6

4

5

9

8

7

2

14.00

IT EM

PAR T N O

D ESCR IPT ION

1

---

DISC ARM

2

P12900

NIPPLE - GREASE M8

3

P14593

HUB CASTING

4

P14594

HUB CAP

5

P12908

SPRING PIN

6

P12907

NUT CASTLE M27x1.5

7

SEAL 64x45x9.5

8

BEARING 32008 40x68x19

9

BEARING 32206 30x62x21

P12415

Fig. 5.01: Checking Disc Bearing Adjustment

5.6 Preparation for

Storage

If you need to store the machine for a longer

period, observe the following points:

Park the machine undercover if

possible.

Protect the roll / discs against rust. If you

need to spray the implements with oil,

use light biologically degradable oils,

e.g. rape oil.

Cover any rubber sections before

using oil sprays. These sections

must not be oiled.

Remove any traces of oil with a

suitable cleaning agent.