Great Plains 3S-4000 Assembly Instructions User Manual

General information assembly instructions, Replacement gearbox, Before you start

Great Plains Mfg., Inc.

Used with:

Update Instructions

© Copyright 1999 Printed 12/13/99

195-231M

30’ 3-Section Drill

Replacement Gearbox

• 30’ 3-Section Drill

General Information

Assembly Instructions

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

the lives of others depend on it!

!!

Before You Start

Beginning on page 5 is a detailed listing of parts

included in each replacement gearbox update.

Use these lists to inventory parts received.

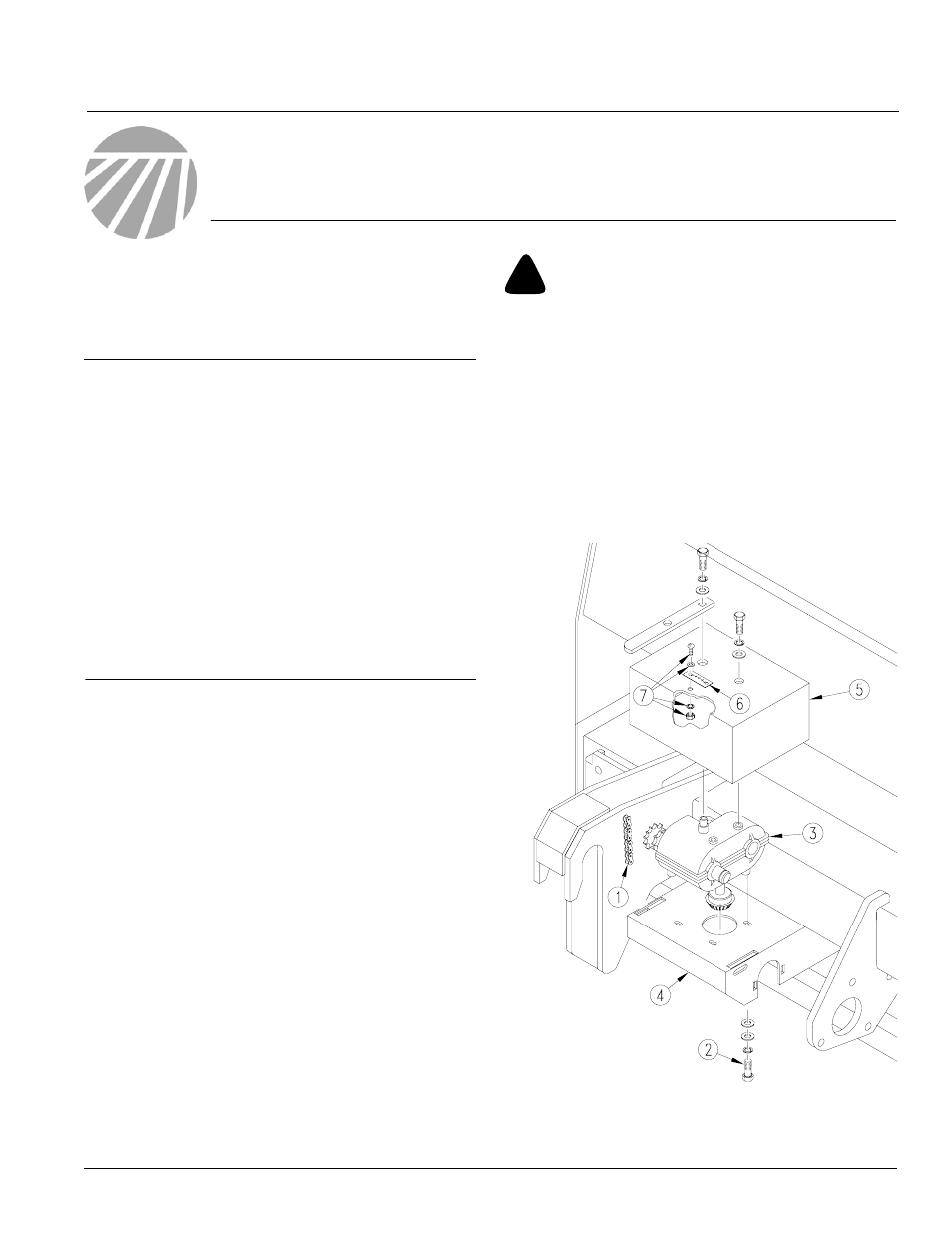

Figure 1

18376

The following instructions and illustrations are for

the right-hand drive. If installing gearbox on left-

hand drive, follow these instructions, remember-

ing that your parts will mirror the illustrations.

NOTE: Some parts are not shown for clarity in the

following illustrations.

1.

Remove chain (1) from gearbox to seed-cup

sprocket. Save chain for later reinstallation.

2.

Remove and discard bolts (2) holding gear-

box (3) on gearbox shelf (4). Remove and dis-

card gearbox and gearbox cover (5). Save

existing brass tag (6) and hardware (7) from

gearbox cover.

NOTE: Save handle from center gearbox drive.

These instructions explain how to install the re-

placement gearbox. The gearbox replaces factory

gearboxes on 30’ 3-section drills built in 1995 and

earlier.

These instructions apply to:

195-226A

30 3SEC GEARBOX REPLACE-

MENT LH

195-227A

30 3SEC GEARBOX RE-

PLACEMNT CTR

195-228A

30 3SEC GEARBOX REPLACE-

MENT RH

Document Outline

- 195-227A 30’ 3-Section Gearbox Replacement-Center

- 195-226A 30’ 3-Section Gearbox Replacement-LH

- 195-228A 30’ 3-Section Gearbox Replacement-RH

- Before You Start

- Figure 1

- 1. Remove chain (1) from gearbox to seed-cup sprocket. Save chain for later reinstallation.

- 2. Remove and discard bolts (2) holding gearbox (3) on gearbox shelf (4). Remove and discard gearbox and gearbox cover (5). Save existing brass tag (6) and hardware (7) from gearbox cover.

- 3. Disconnect clutch (8) and remove from bracket.

- 4. Remove bolts from bearing flanges (9) on gearbox jackshaft (10).

- 5. Remove jackshaft and disassemble bevel gear (11) and set collar (12) from jackshaft. Discard bevel gear and set collar.

- 6. Replace bevel gear with 16-tooth sprocket (13) from kit using key (14) from preexisting bevel gear. Do not tighten set screws on sprocket at this time.

- 7. Reinstall jackshaft and reconnect clutch.

- 8. Using four 3/8-inch, self-tapping screws and lock washers (15), bolt new gearbox (16) onto mounting plate (17).

- 9. Mount 16-tooth, spline-bore sprocket (18) on gearbox input shaft above idler bracket. Mount 12-tooth, spline-bore sprocket (19) on gearbox output shaft. Secure sprockets with snap rings.

- 10. Mount 12-tooth sprocket (20) on idler bracket in this order: 1/2-inch bolt, sprocket, jam nut, flat washer, bracket, lock washer, and nut.

- 11. Torch a rectangular access hole (21) in existing gearbox shelf. To locate access hole, hold new gearbox and mounting plate over gearbox shelf. Align gearbox output sprocket (19) with seed-cup sprocket. Mark idler bracket location.

- 12. Use mounting spacers (22) and 3/8 x 1 1/2 inch bolts (23) to bolt mounting plate and gearbox on gearbox shelf.

- 13. Align drive sprocket on jackshaft with gearbox input sprocket (18). Tighten set screws on drive sprocket

- 14. Route chain provided in kit over jackshaft drive sprocket and gearbox input sprocket (18). Use new idler (20) to remove chain slack. Refer to Figure 5 for chain routing.

- 15. Reroute chain removed in step 1 over gearbox output sprocket (19) and seed-cup sprocket. Refer to Figure 5 for chain routing.

- 16. Refer to Figure 3 and assemble new gearbox cover (24) on gearbox using two 3/8-inch, self-tapping screws (25).

- 17. Assemble gearbox handle (26) onto gearbox with 1/4-inch bolt, lock washer and flat washer.

- 18. Attach brass tags removed in step 2 to new gearbox covers.

- Chain Routings

- Figure 6

- 19. Weld the idler mount plate to the frame tube using the dimensions shown as a guide.

- 20. In each slot on idler mount plate, attach a 12- tooth sprocket in this order: 1/2-inch bolt, sprocket, jam nut, flat washer, idler mount plate, lock washer, and nut.

- 21. Route chain around idlers and tighten to remove slack. Refer to Figure 5 on the previous page for chain routing.

- 22. Go back to step 16 on page 3 and continue with gearbox assembly instructions.

- General Information

- Assembly Instructions