Great Plains 24 Series Drills Assembly Instructions User Manual

General information, Assembly instructions, Folding markers

1

Installation Instructions

Great Plains Mfg., Inc.

© Copyright 1998 Printed 11/25/98

Used with:

•

•

•

113-672M

24 Series Drills

Folding Markers

2400

2410

2420

General Information

These instructions explain how to install the optional markers.

The markers fold and unfold hydraulically for field operation. The

marker disks leave a line for the drill operator to follow on the next

field pass. Markers are mounted on the drill frame and require

two hydraulic remote valves on the tractor. A sequence valve is

available so markers can be operated on one hydraulic circuit.

These instructions apply to:

113-662A

24FT 3PT DUAL MARKERS

113-466A

94 3PT SEQ VALVE KIT-FIELD

Manual Update

Refer to the drill operator’s manual for detailed information on

safely operating, adjusting, troubleshooting and maintaining the

markers. Refer to the parts manual for part identification.

• 2400, 2410 and 2420 Operator’s Manual. . . . . . .118-706M

• 2400, 2410 and 2420 Parts Manual. . . . . . . . . . 118-706P

Before You Start

Starting on page 4 are detailed listings of parts included in

the option packages. Use these lists to inven-

tory parts received.

Assembly Instructions

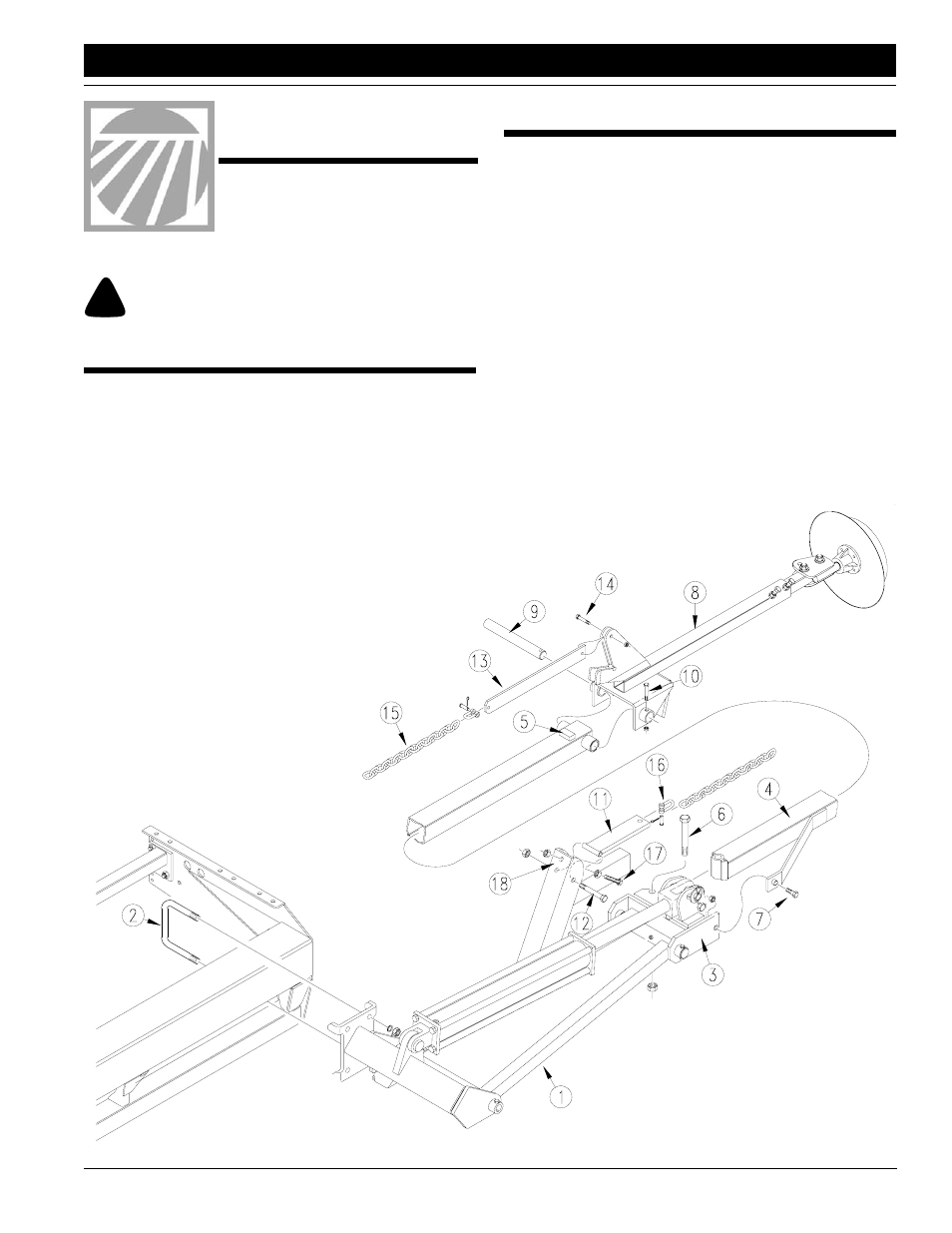

Marker Assembly

1.

Lower drill into field position. Allow 15 feet of clearance from

each end of drill box for marker assembly.

2.

Attach first marker section (1) to drill frame. Mount marker

as far out on drill frame as possible. Secure marker to drill

frame with 5/8-inch u-bolts (2), lock washers and hex nuts.

3.

Remove port plugs from marker cylinder and carefully un-

fold first marker section. Rotate hinge (3) into a horizontal

position.

4.

Assemble second marker section (4) onto first section so

that stop block (5) on second section faces up. Secure sec-

tions with 5/8-inch bolt (6) and lock nut and 3/8-by-2-inch,

grade 2 shear bolt (7) and lock nut.

IMPORTANT: Use a grade 2 bolt for the shear bolt or marker

damage will occur during field operation.

5.

Place third marker section (8) over end of second section

and insert hinge pin (9) through second- and third-section

pivot. Secure hinge pin with the 1/4-by-2-inch bolt (10) and

lock nut.

6.

Bolt chain pivot (11) to first marker section with 3/8-by-3 1/4-

inch bolt (12) and lock nut so chain pivot pivots freely on bolt.

7.

Bolt chain bar (13) to third marker section

with the 3/8-by-1 1/2-inch bolt (14) and

lock nut so chain bar pivots freely on bolt.

8.

Con-

nect

marker

chain

(15) to

chain bar

and chain

pivot with utility

clevis (16). With

marker disk adjusted

for seeding width and

disk touching the

ground, remove chain slack with

utility clevis nearest drill.

9.

Assemble full-threaded, 3/8-inch stop bolt

(17) and lock nuts on lift-arm extension (18) so

head of stop bolt extends as little as possible.

After the marker is bled and folded, adjust stop

bolt to remove slack from chain. Refer to Mark-

er Chain Adjustments, "Adjustments" in the

operator’s manual.

Figure 1

Marker Assembly

17628

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

the lives of others depend on it!

!!