Calibration overview, Calibrate with drill raised, Calibrate for 1/10th acre or hectare – Great Plains 1007NT Material Rate User Manual

Page 4: Calibration crank storage, Using calibration crank, Calibrate with drill raised calibrate for, Calibration crank storage using calibration crank, Caution

Great Plains Mfg., Inc.

2

150-290B

07/08/2009

Calibration Overview

Detailed calibration steps vary with each box.

Some general information applies to all boxes.

Calibrate with Drill Raised

Perform the calibration with the drill hitched and raised.

Install cylinder locks.

Calibrate for

1

/

10

th Acre or Hectare

The number of revolutions per area is:

Calibration Crank Storage

!

CAUTION

Contaminated Sharp Object Hazard:

Exercise care when working with and around the ground drive

wheel. The teeth on the rim may be sharp, and may be coated

with soil and/or agricultural chemicals.

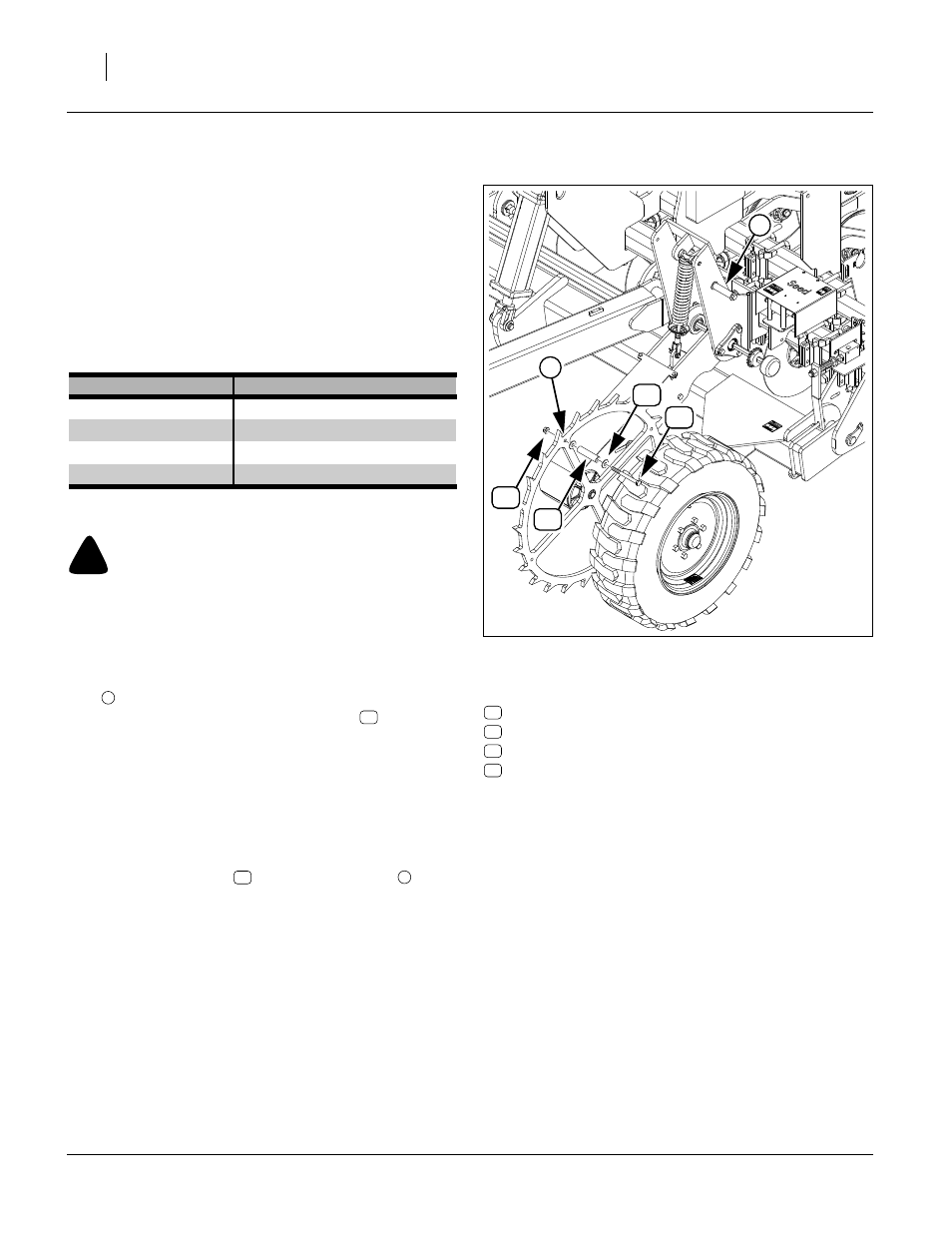

Refer to Figure 1

A calibration crank handle assembly is stored at a

hole

on the upper left side of the main (left) ground

drive weldment. It is secured by a lock nut

, and may

require a

3

⁄

4

in (19 or 20mm) wrench for removal.

Access to the ground drive wheel is easier if it is locked

up. See “Ground Drive Lock Up” in the drill Operator

Manual. Be sure to lower drive before planting.

Using Calibration Crank

Remove the crank handle from the storage hole on the

weldment. Insert its bolt

in any available hole

at the

rim of the ground drive wheel. Tighten the lock nut

loosely, to permit handle rotation.

Use the handle to rotate the wheel counter-clockwise.

A wide range of cranking speeds produce accurate cali-

brations. For reference, at 6 mph (10 kph) field speed,

jackshaft rpm is 57 (about 1 revolution per second).

Crank Handle Parts Reference:

152-584D HANDLE TUBE

802-046C HHCS 1/2-13X5 1/2 GR5

803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

804-017C WASHER FLAT 1/2 USS PLT

Figure 1

Calibration Crank Handle

28470

11

12

13

14

2

1

11

13

12

14

Area Sampled

Wheel Revolutions

Full Acre

491.6

49.2

Full Hectare

1214.8

121.5

1/10

th

Acre

1/10

th

Hectare

13

12