Adjusting the valve – Great Plains 2S-2600 Assembly Instructions User Manual

Page 6

195-298M

4/19/2007

Great Plains Mfg., Inc.

Counterbalance Update

6

Adjusting the Valve

On the stem of the valve there is a rubber cap that

protects the threads of an adjustment stem. This

stem is locked in place with a hex nut. To adjust

the valve, loosen the nut and turn the stem using

an Allen wrench.

Screwing the stem in (clockwise) pushes on a

spring which supplements the pilot line’s force on

an internal piston. More spring force will let the

valve open with a low pilot pressure. Less spring

force will require higher pilot pressure to open the

valve.

Note: With the screw turned in fully, the spring will

develop enough force on the piston to unlock the

valve, even with no pilot pressure, causing the

openers to settle.

Raise and lower the drill several times then hold

hydraulic down pressure on the openers to purge

air from the system and to warm the oil. Repeat.

Raise the openers. Observe the openers closely

to detect settling. If the openers remain up, no

valve adjustment is needed.

If the openers settle, the stem is screwed in too far.

Gently back the stem out until it stops, then screw

it in one turn. Generally this is a good starting

point. Check for settling.

Backing the stem out will lock the valve, screwing

it in too far can cause it to unlock.

A small increase in lowering speed can be

achieved by screwing the stem in.

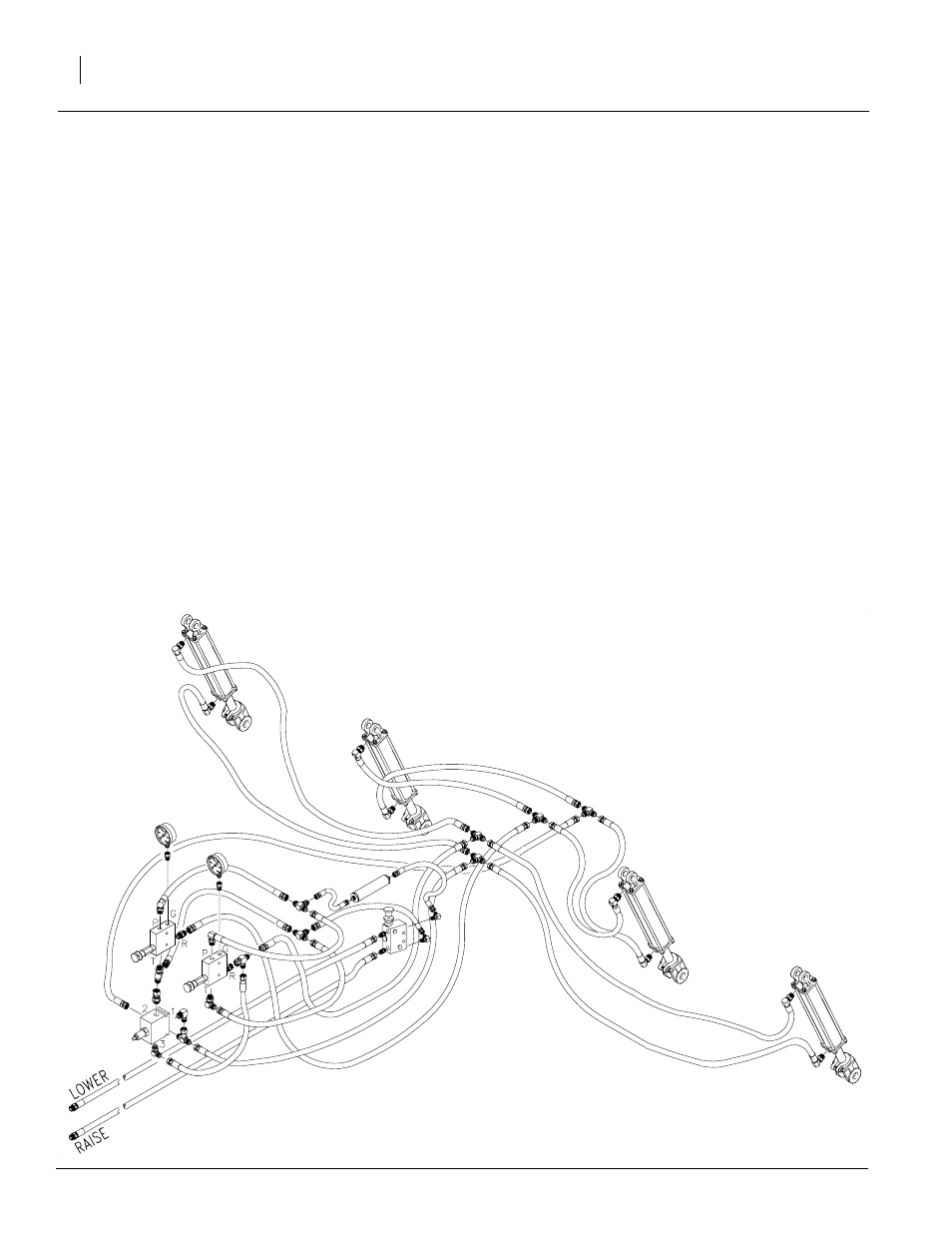

2S-2600 November 2003 and later Plumbing Diagram. (no point row or open center kit)

21798