5 double disc axles, 4 brakes & wheel hubs, 2 bearing seals – Great Plains P15845 Serial No 18007975 User Manual

Page 31: 31 x-press, Servicing and maintenance

31

X-Press

Operating Instructions

5. Servicing and Maintenance

5.5 Double Disc Axles

The axles on this roller are tensioned by the

main axle through the centre of the rings and

bearings.

Specialist equipment is required

for the disassembly of Double Disc

axles. Please consult your dealer

under any circumstances that

require disassembly of these

axles.

Maintenance of these rollers is limited to daily

greasing of the bearings to flush out dirt, and

regular inspection to ensure the assemblies

are tight, and scrapers are correctly set. The

axles can be tightened provided the bearing

pillar ‘U’ bolts are loosened to avoid

preloading the bearings as they move

sideways to each other. Ensure the bearing

pillars are re- tightened to the mainframe after

this.

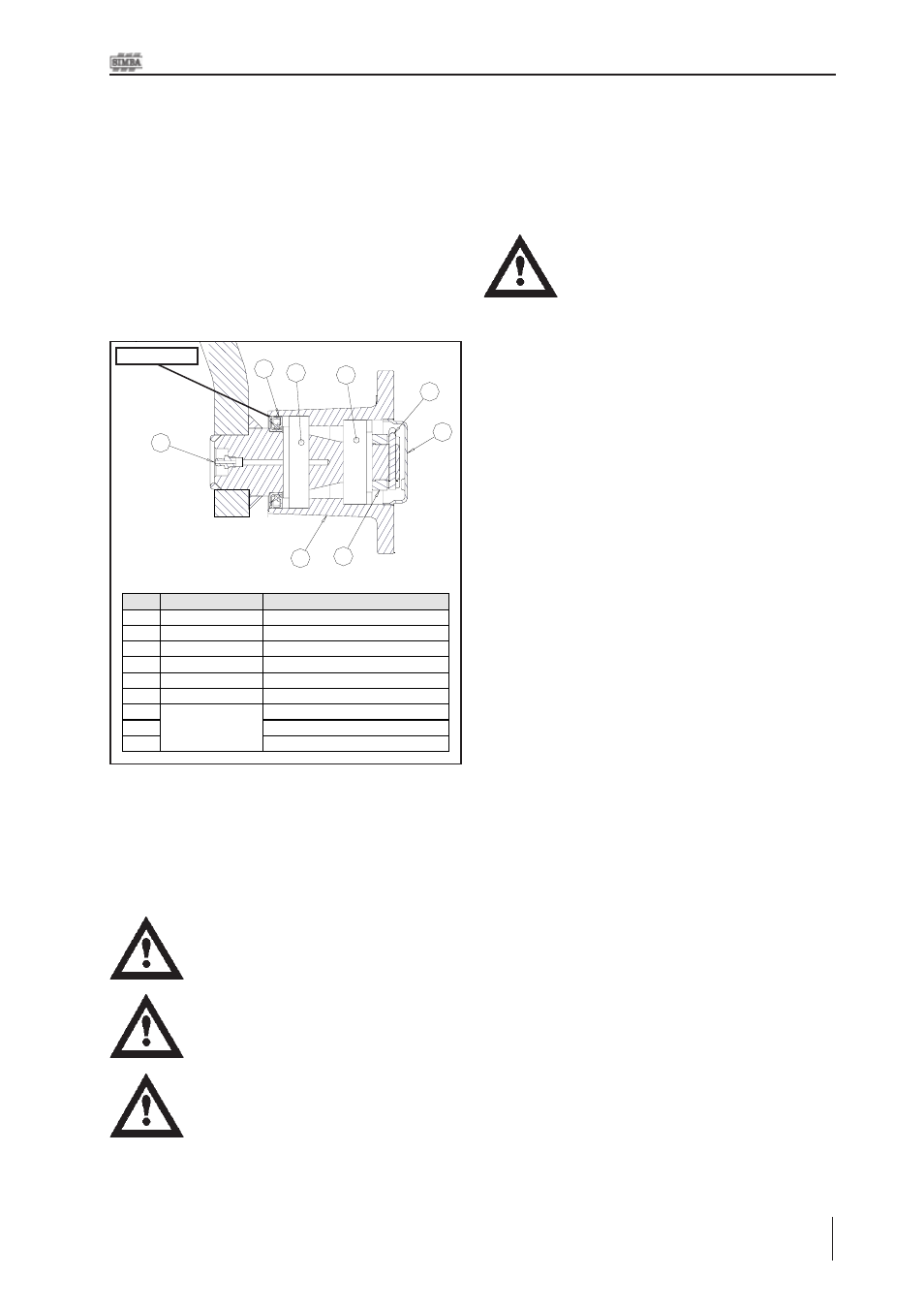

5.3.2 Bearing Seals

It is important when replacing the labyrinth

type bearing seals in disc hubs that the seal

is fitted the right way round. The chamfered

lip side should be at the outside of the bearing

housing, nearest the disc arm (see Fig. 5.02).

This chamfered lip prevents dirt ingress into

the housing and also allows grease to be

flushed though when greasing.

Chamfered Seal

Fig. 5.02: Correct Seal Orientation

3

6

4

5

9

8

7

2

14.00

IT EM

PAR T N O

D ESCR IPT ION

1

---

DISC ARM

2

P12900

NIPPLE - GREASE M8

3

P14593

HUB CASTING

4

P14594

HUB CAP

5

P12908

SPRING PIN

6

P12907

NUT CASTLE M27x1.5

7

SEAL 64x45x9.5

8

BEARING 32008 40x68x19

9

BEARING 32206 30x62x21

P12415

5.4 Brakes & Wheel Hubs

The brakes should be tested before using for

the first time and after the first laden journey.

Check that the road and parking

brakes operate and release

correctly before using the machine.

Check for hydraulic fluid and air

leaks.

Brake and hub maintenance and

servicing should be carried out by

an authorised Simba dealer.