Section 6 troubleshooting, All seeds hitch troubleshooting – Great Plains AS20 Operator Manual User Manual

Page 31

-

29

4/14/05

Great Plains Mfg., Inc.

Section 6 Troubleshooting

AS15 and AS20 Planting System 148-153M

Section 6

Troubleshooting

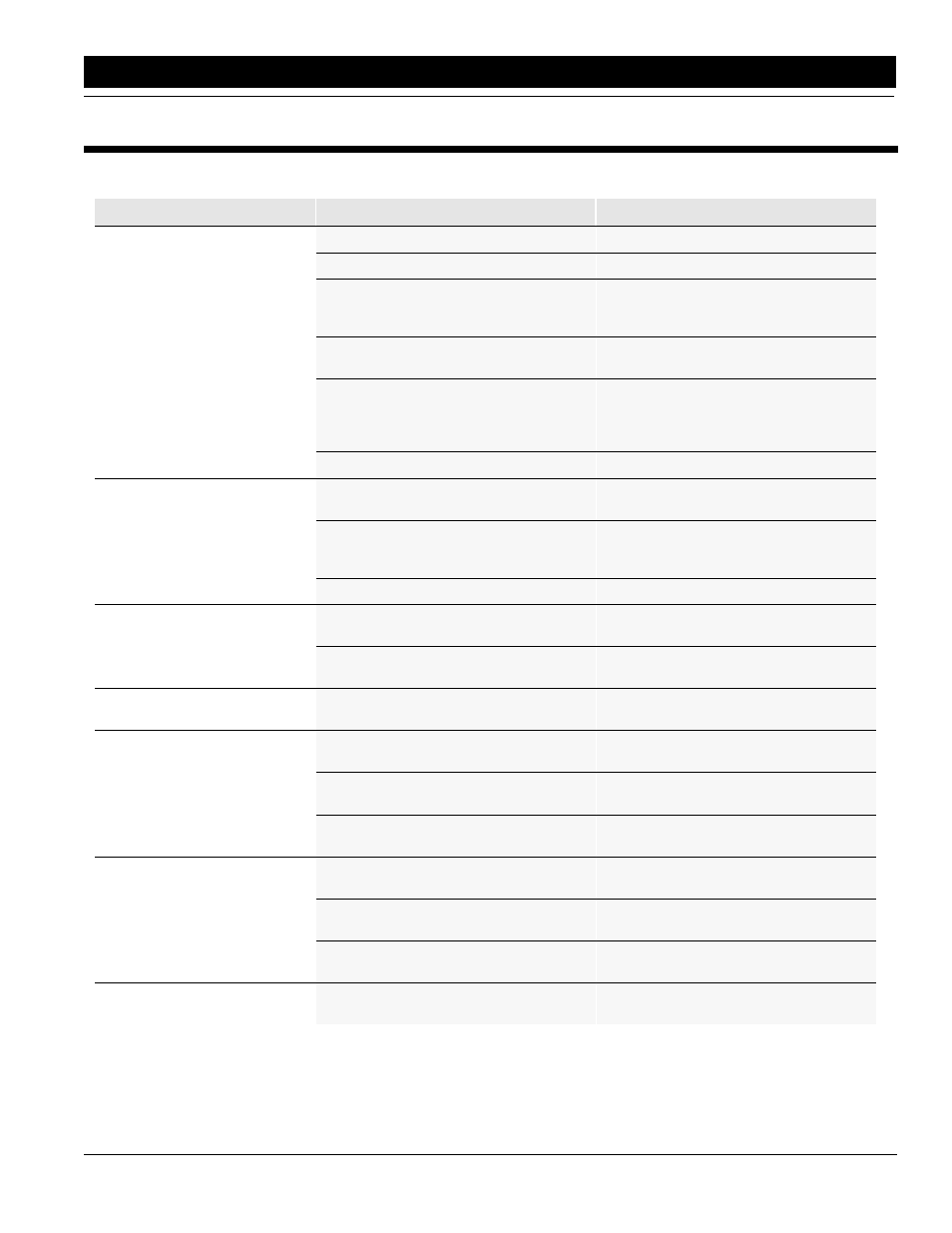

All Seeds Hitch Troubleshooting

Problem

Possible Cause

Solution

Coulters not going deep enough

Tongue cylinder is extended to much

Retract front tongue cylinder.

To much weight is being use by openers

Set drill openers to lightest spring setting.

Not enough weight

Add suitcase weights to transport frame

weight brackets (DO NOT add more than

2000#)

Coulters are not set to a high enough initial

spring compression

Increase initial compression on individual

coulter springs.

Not enough weight

Add coulter tool bar weight brackets & suit-

case weights to ends of coulter tool bars.

(DO NOT add more than 2400#) on coulter

tool bars.

To high of setting on coulters

Lower individual coulter spring bars on tool bar.

Drill not tracking behind coulters.

Coulters out of alignment with openers

Check that coulters and drill openers are

same distance from center.

Pivot locks are not in drilling position

Check that pivot locks are in the up position

while drilling. Make sure they were not

manually locked down.

Leaf spring is out of alignment

Check for proper adjustment of leaf spring.

Uneven seed spacing or uneven

stand.

Drive gauge wheel are not making enough

contact with ground

Make sure drill and planter are equipped

with down floating drive gauge wheels

Binding in gauge wheel link

Check that gauge wheel link is free to float

in slotted hole

Openers plugging in no-till condi-

tions.

Drilling parallel to standing residue

Plant at a slight angle to the rows.

Drill is planting too deep.

Level link is letting drill tip back to much

Adjust top level link so that drill will not tip

back in planting position

To deep of setting on press wheels

Move press wheel adjustment on openers

to shallower depth.

To much drill weight for conditions

Add cylinder stops to lift cylinders so that

transport tires are on the ground.

Planter planting too deep

Level link is pushing planter back too far.

Adjust top level link so planter frame is

level.

Too deep of side depth gauge wheel set-

ting.

Move side depth wheel adjustment too

shallower setting

Too much weight for conditions.

Planter gauge wheels sinking too deep.

Add cylinder stops to lift cylinders so that

transport tires are on the ground.

Transport lift cylinders

loosing lift height

Rod end of clevis pin and bushing wear

Inspect and replace rod end cylinder clevis

pin and bushings.