Aaf fk k f fl la an ng ge e f fa an n – CFM AFK-0906 User Manual

Page 2

A

AF

FK

K F

FL

LA

AN

NG

GE

E F

FA

AN

N

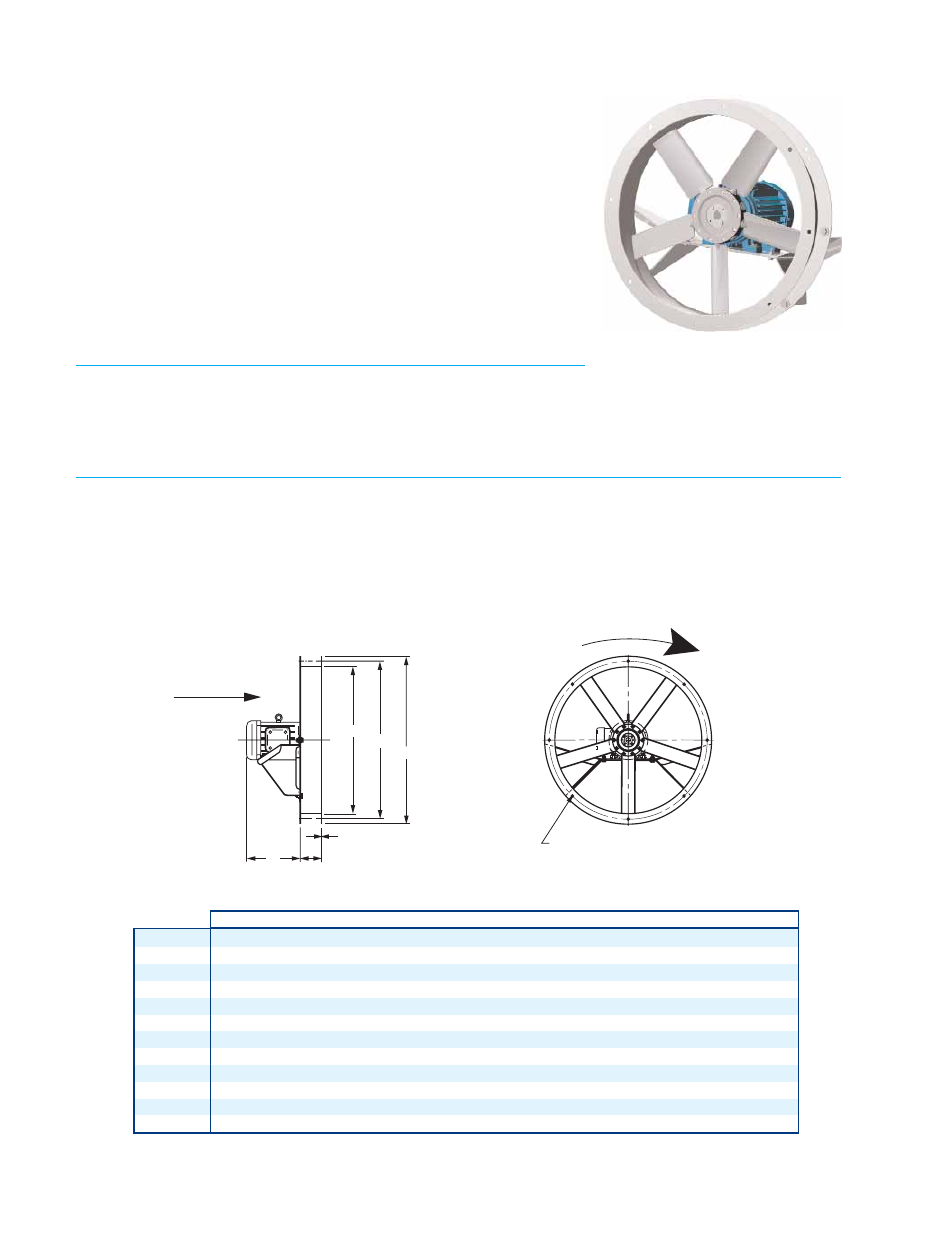

H DIAMETER 8 HOLES EQUALLY SPACED ON

CENTER LINES ABOUT B BOLT CIRCLE DIA.

STANDARD

ROTATION

STANDARD

AIRFLOW

DIRECTION

A

B

C

T

J

U

MAX

*DO NOT USE FOR CONSTRUCTION

CONSULT FACTORY FOR CERTIFIED PRINTS

MODEL

A

B

C

H

J

T

U MAX

MAX MTR FRAME

AFK-12

12.2

13.8

15.0

0.44

3.0

0.06

11.5

143/5T

AFK-14

14.2

16.3

17.5

0.44

3.0

0.06

11.5

143/5T

AFK-16

16.2

18.0

19.5

0.44

4.0

0.08

11.5

143/5T

AFK-18

18.2

20.8

22.0

0.44

4.0

0.08

11.5

143/5T

AFK-21

21.2

23.3

24.5

0.44

4.0

0.08

11.5

143/5T

AFK-24

24.2

26.3

27.5

0.44

4.0

0.08

11.5

143/5T

AFK-27

27.2

29.3

31.0

0.44

4.0

0.08

13.3

182/4T

AFK-30

30.2

32.6

34.5

0.44

4.0

0.11

16.5

213/5T

AFK-32

32.2

34.4

36.5

0.44

4.0

0.11

16.5

213/5T

AFK-36

36.2

38.4

40.5

0.44

5.0

0.11

16.5

213/5T

AFK-42

42.2

44.6

46.5

0.44

5.0

0.11

21.5

254/6T

DIMENSIONS IN INCHES*

S

ST

TA

AN

ND

DA

AR

RD

D F

FE

EA

AT

TU

UR

RE

ES

S &

& B

BE

EN

NE

EF

FIIT

TS

S

•

Airfoil adjustable pitch cast aluminum impeller

•

Unit can be built for supply or exhaust configurations

•

Superior performance and sound characteristics

•

Heavy gauge steel with baked polyester coating

•

GRP (polypropylene) blades available

•

Ideal for OEM applications or new construction

•

Fully reversible design option available

•

Advanced computerized selection program

•

Sizes range from 12” to 42”

•

Capacities to 34,000 cfm

A

AP

PP

PL

LIIC

CA

AT

TIIO

ON

NS

S

•

General ventilation

•

Marine / Shipboard applications

•

Renewable energy

•

Industrial drying

•

OEM condensing units

•

Circulation / Recirculation units

A

AC

CC

CE

ES

SS

SO

OR

RIIE

ES

S // O

OP

PT

TIIO

ON

NS

S

•

Mounting panel

•

AMCA spark resistant construction

•

Motor side guard

•

Reverse flow construction

•

Propeller side guard

•

Special materials

•

Explosion proof motors

•

Special coatings

•

Special duty motors

•

Housing yoke with mounting bracket

2