Lk clutch or brake design features – Wichita Clutch LK Clutch User Manual

Page 2

33

I N D U S T R I A L C L U T C H P R O D U C T S

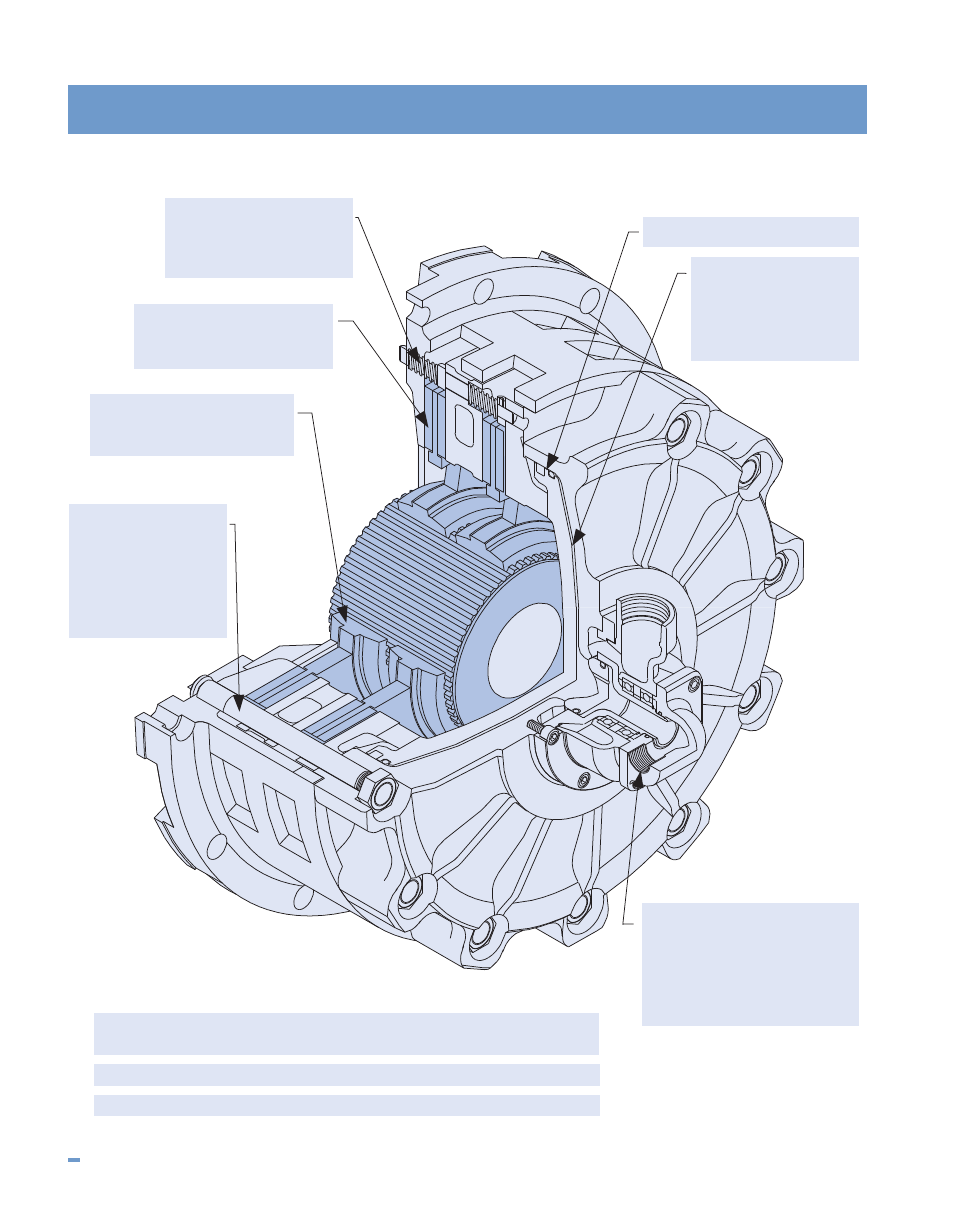

LK Clutch or Brake Design Features

Clutch designed with total attention given to maximizing ventilation for cool running operation. Benefits

include: longer lining life; stable friction coefficients; and lower maintenance costs.

All materials selected and field proven to provide the best available resistance to wear and thermal distress.

Precision machining of all components ensures positive interchangeability of all mating parts.

Self-contained separator springs for

positive disengagements are integral

with each plate and cannot fall out

upon assembly or disassembly.

High quality non-asbestos lining

materials and maximum areas ensure

excellent heat dissipation and lining life.

Longest possible spline length incorpo-

rated on the clutch discs to maximize the

load-carrying capacity and life.

Drive studs ensure free plate

motion during engagement and

disengagement. The use of

drive studs, rather than splines,

allows wear particles and other

contaminants to exit the clutch

as well as provides an excellent

path for cooling air flows.

Long life, low replacement cost piston seals.

Short-stroke lightweight alumi-

num piston is contour machined

to match the cylinder recess and

provides for extremely fast clutch

response with minimal air

consumption.

Rotary seal and integral quick release valve

mounts directly to the clutch cylinder.

Custom drilled orifices per application and

clutch size in a large poppet style valve,

meters the inlet air to provide smooth,

shockless engagements and allows for

immediate release upon command.