Parts list, Clean-up, Disassembly – Trebor 120E Mega User Manual

Page 16: 5 parts list, 6 clean-up, 7 disassembly

PAGE 16

MEGA 120E PUMP OPERATION / MAINTENANCE MANUAL

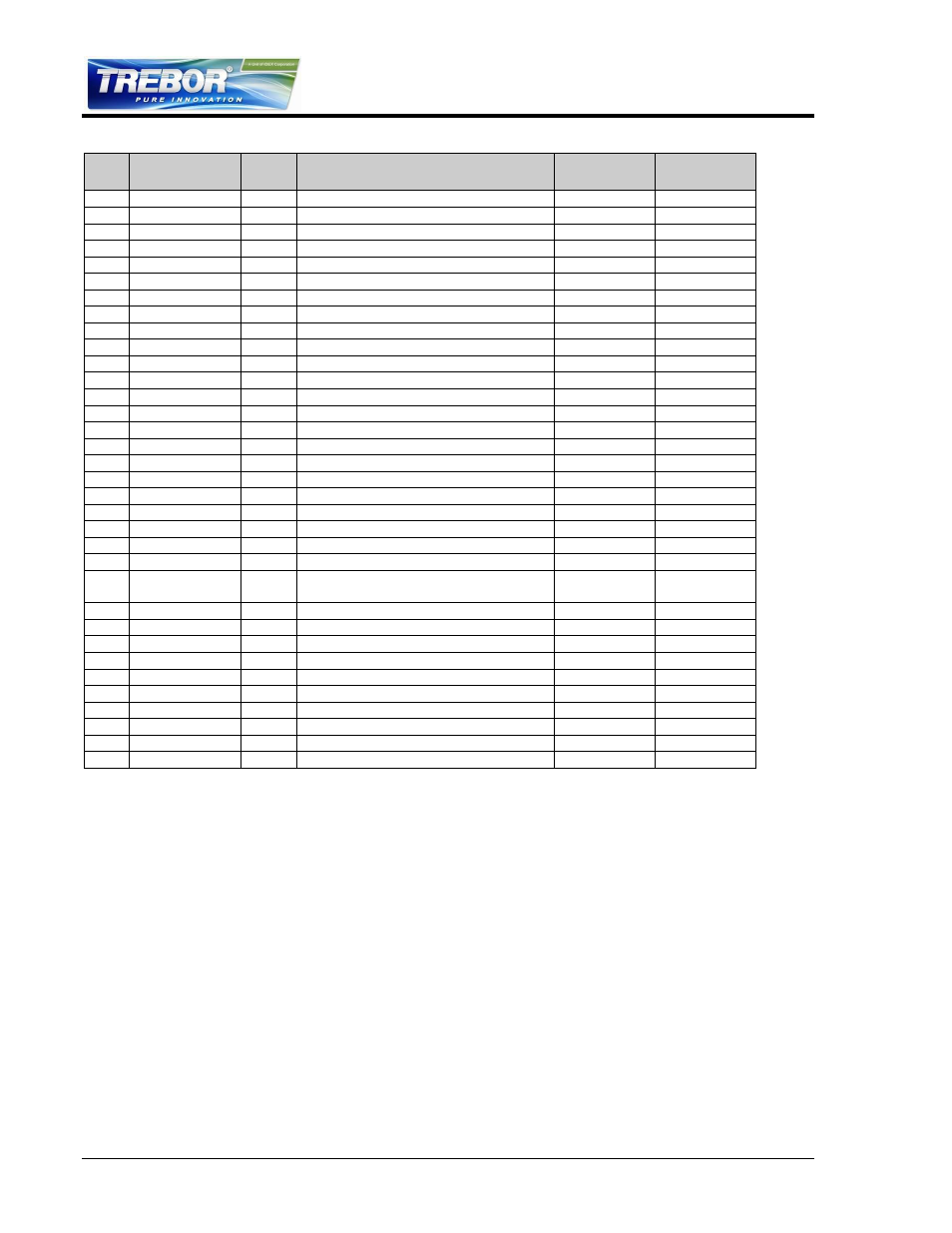

4.5 PARTS LIST

ILL

NO

PART NO

QTY

DESCRIPTION

PM

YEAR #

MATERIAL

1

BL006

2

Check Bore Plug

PTFE

2

BL007

2

Gasket Seal, Check Port

1

PTFE

3

BL004

2

Discharge Sleeve

PTFE

4

98004255

4

Check Ball

1

PTFE

5

98004258

4

O-Ring

1

PTFE

6

BL003

2

Suction Sleeve

PTFE

7

BL002

2

Suction Seat

PTFE

8

BL001

1

Body

PTFE

9

BL012

1

Shaft Bushing

1

PTFE

10

L0195

1

Locking Ring

PTFE

11

BL011

1

Main Shaft

2

PFA

12

1900B0070

2

Push Plate

PTFE

13

1900B0023

2

Diaphragm Set

1

PFA

14

98001585

2

Main Seal

1

Viton

15

L0185-01

2

Head

PP

16

L0184

8

Spacer, Tie Bolt

PP

17

BL014

8

Tie Bolt Assembly

SS316, PFA

18

L0100

16

Tie Bolt Cap

1

LDPE

19

98003047

2

Quick Exhaust Seal

1

Viton

20

1900B0016

2

Quick Exhaust Port

UHMW

21

L0119

2

Assembly, Muffler

1

PP

22

98002243

10

Plug, 3/8 NPT

PE

23

98003514

2

Fitting, Air

PP

24

L0140

8

Bushing

NPRN &

EPDM

25

1900A0028-01

8

Tie Bolt Washer

SS316

26

98002341

8

Nut, Flange, SS, 1/4 - 20

SS18-8

27

98001418

4

Insert

SS18-8

28

BL017

1

Pump Base

PP

29

98001093

4

Washer

SS18-8

30

98001375

4

Screw

SS18-8

31

98001108

4

Cap, Blue

LDPE

32

98003755

1

Screw, Lock Ring

PTFE

33

98003769

2

Screw, Push Plate

PTFE

34

AW073

2

End-of-Stroke Port Plug

PTFE

4.6 CLEAN-UP

To help remove potentially dangerous chemicals, the pump can be flushed with DI water

or disassembled and thoroughly cleaned. Take all appropriate safety precautions

commensurate with the chemical risks of the fluid.

4.7 DISASSEMBLY

During the life of the pump it will be necessary to perform certain preventative

maintenance procedures to ensure its continued high performance. This section and the

next (4.8 Assembly

) are provided for the user’s convenience in disassembly and re-

assembly in performing these procedures.

Thoroughly clean/flush the pump using DI water (Refer to Section 4.6).

Remove tie bolt caps from the slave head.

Remove nuts from the tie bolts (Slave Head side). Leave tie bolts in place.

Lay the pump on its side with slave side up.