Trebor 50R Maxim User Manual

Page 19

MAXIM 50R PUMP OPERATION / MAINTENANCE MANUAL

PAGE 19

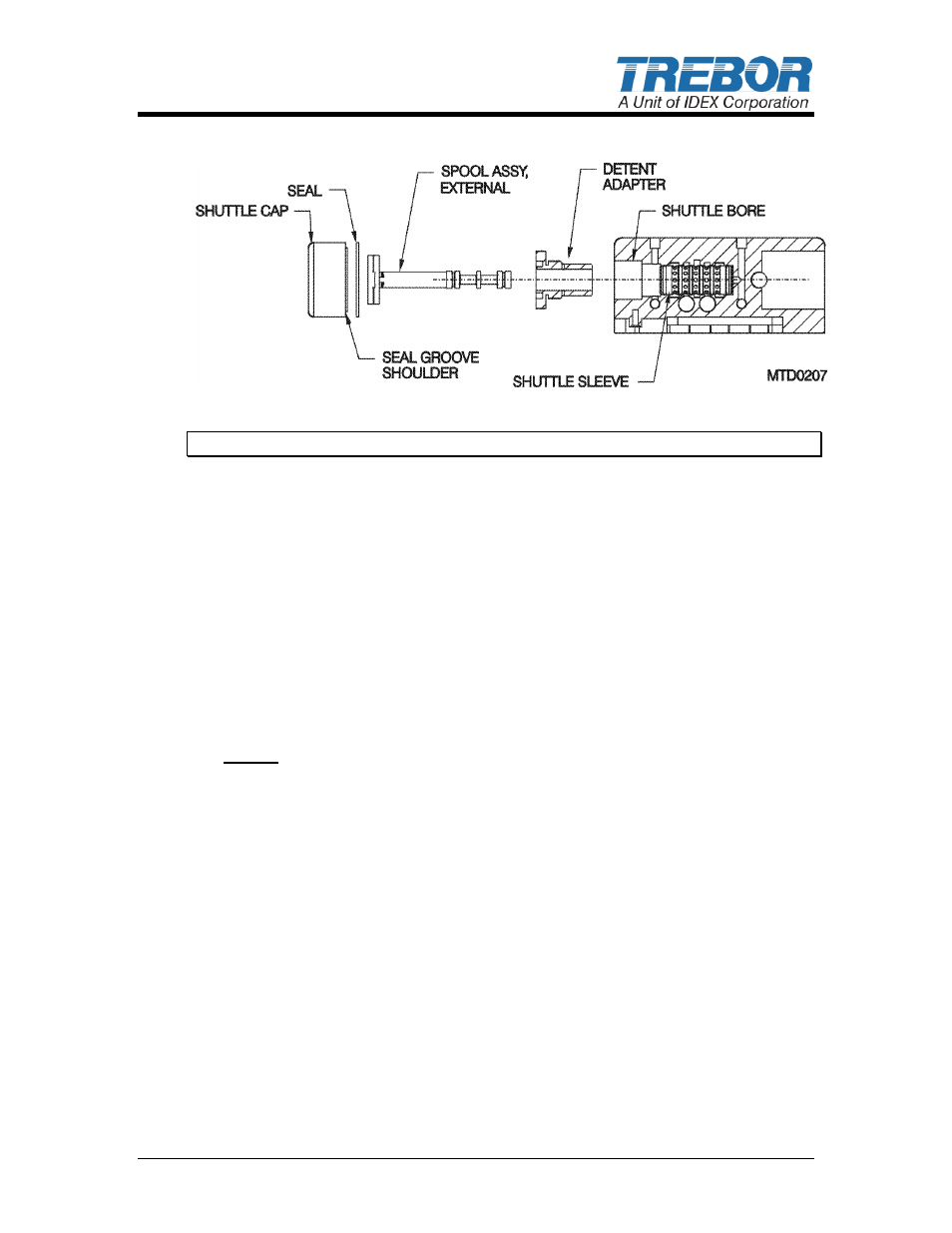

Thread shuttle cap onto detent adapter, torque to 40in-lbs

.

hand tight.

Figure 4-4

ATTENTION: Threads should be snug. Do not over tighten.

Thread muffler assembly into base

using 1” pin tool, torque to 40in-lbs.

4.8.b Body Assembly

Install seal and damper plug into body using 3/4” pin tool, torque to 50in-lbs.

Remove pump from assembly fixture.

Turn pump upside down to access check bores.

Install discharge check cage into bore making sure small end fits into relief in

bottom of bore.

Drop ball into check cage, then O-ring.

In

stall suction sleeve into the bore; tighten using 1” pin tool. Tighten until

engagement with O-ring is achieved, then unthread the sleeve a quarter turn.

Do not over tighten as damage may occur.

Install second ball into check cage, then O-ring.

Install suction

seat using the 1” pin tool. Tighten until engagement with O-ring

is achieved, then unthread the seat a quarter turn.

Install check seal onto check bore shoulder and thread suction plug into bore

using 1” pin tool, torque to 60in-lbs.

Repeat for the second bore.

Install two shaft seals in shaft bore groove with slits 180

apart.

Thread push plate onto main shaft until engagement with the shaft shoulder

is achieved. Additionally apply a ¼” turn to ensure proper installation.

Thread shaft onto shaft insert tool and insert shaft into bore.