thumbsUp Space Coaster User Manual

Space coaster, A shown b shown [c1] corner part, C2] corner part b

2

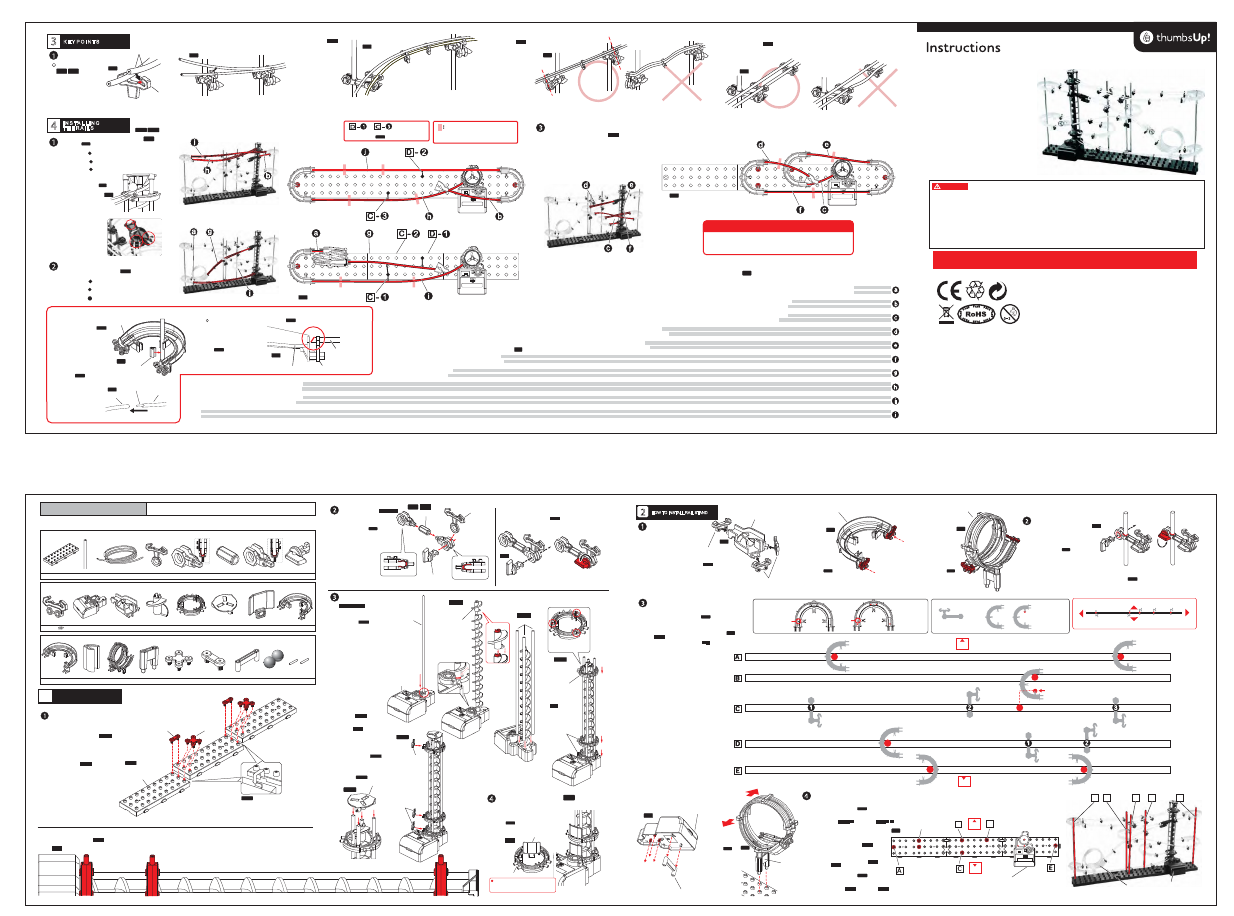

INSERT TWO RAILS

g

INTO THE LOOP PART AND FORK PART

INSERT TWO RAILS

a

INTO THE LOOP PART AND CORNER PART

INSERT TWO RAILS

i

INTO THE CORNER PART AND ELEVATOR

FORK1---LOOP---ELEVATOR ENTRY1

22

BACK 487mm

FRONT 487mm

BACK 415mm

FRONT 416mm

BACK 415mm

FRONT 420mm

FRONT 73mm

BACK 26mm

FRONT 26mm

TEST TO SEE IF THE STEEL BALL STOPS OR FALLS OFF, IF SO PLEASE ADJUST THE RAIL TO

ENSURE IT RUNS SMOOTHLY ON THE RAIL.

A6 RAIL STAND

REFER TO THE PIC WHEN INSTALL THE RAIL STAND

25

25

THE FOLLOWING PICS ARE 1:1 SCALE TO RAIL, REFER THESE PICS TO CUT THE RAIL

CUT THE FRONT RAIL WITH PLIERS

BACK 309mm

FRONT 313mm

BACK 275 mm

FRONT 273 mm

BACK 162mm

FRONT 157mm

BACK 174mm

FRONT 170mm

ヘシ22

24

23

26

INSERT TWO RAILS

d

INTO THE CORNER PART AND FORK PART

INSERT TWO RAILS

f

INTO THE CONNER PART

INSERT TWO RAILS

e

INTO THE CONNER PART

INSERT TWO RAILS

c

INTO CONNER PART AND ELEVATOR

3

FORK2CORNERELEVATOR ENTRY 2 (END)

PIC.23

~

D

1

C

3

INSTAL AS SHOWN

11

BACK 73mm

FRONT 79mm

THE WAY TO CONNECT THE RAIL AND CORNER PART

24

CUT THE FRONT RAIL WITH PLIERS

AS

24

I TO PREVENT THE STEEL BALL

RUNNING INTO IT.

RAIL INSTALLATION

15

16

。HOW TO INSTALL THE RAIL

1

[R1] RAIL

[A1] ARM

INSERT THE RAIL INTO THE ARM

ADJUST THE BEND OF THE RAIL BEFORE INSTALLING

15

K E Y P O I N T S

3

IF THE DISSTANCE BETWEEN ARMS IS TOO LONG

ADD RAIL STAND 23 TO KEEP STABILITY

(DISTANCE BETWEEN ARMS IS 8cm-10cm)

17

SET THE RAIL STAND

16

。ABOUT THE RAIL STAND

17

THE DISTANCE BETWEEN THE

ARMS ABOUT 8CM- 10CM COULD

ADD THE RAIL STAND IF THE

GAP IS GREATER

.

FIX THE RAIL STAND AT THE

BRAKE POINT OR ELEVATOR

DOOR TO STABILIZE THE RAIL

19

2 INSTALL THE RAIL STAND TO KEEP RAILS BALANCE PARALLEL

。THE DISTANCE BETWEEN RAILS

PIC.19

INSTALL WITH AN INCLINE AT

AT BRACE PLACE

18

MAKE THE ARM INCLINE AS pic20

MAKE THE BRACE THIS WAY

TO ENSURE THE BALL RUNS

SMOOTHLY

。ABOUT THE BRACE

K18

THE SECRET TO KEEPING THE ROUTE STABILE

。ABOUT THE CORNER STAND

26

。RAIL JOINING

27

4

I N S TA L L I N G

T H E R A I L S

21

LET THE RAIL RUN CLOSE TO THE HELIX

AT THE ELEVATOR EXIT TO ENSURE THE

STEEL BALL RUNS SMOOTHLY.

。HOW TO INSTALL THE ELEVATOR EXIT

21

20

1

EXIT-----FORK

PIC20

INSERT TWO RAILS

b

INTO THE CORNER PART AND FORK PART

INSERT TWO RAILS

j

INTO THE ELEVATOR AND CONNER PART

INSERT TWO RAILS

h

INTO THE ELEVATOR AND CONNER PART

REFER TO THIS PIC WHEN INSERTING

THE RAIL INTO FORK

[R1] RAIL

[R2] RAIL JOINING PART

[R1] RAIL

27

[C3] CORNER STAND

CORNER

FINISH ASSEMBLING

[R1] RAIL

[C1] [C2] CORNER PART [A6] RAIL STAND

BACK 70MM

THIS RAIL INCLUDES ONE ELEVATOR EXIT AND TWO ENTRANCES, REFER TO

20 24

WHEN INSTALLING

CORNER PART A

CORNER PART A

CORNER PART A

INSERT ALL SHAFTS INTO THE BASE THEN INSTALL THIS PART.

CORNER PART B

CORNER PART A

FRONT

CORNER PART B

CORNER PART B

[S2] SHAFT 300mm

BACK

THE WAY TO DISTINGUISH CORNER PART

A SHOWN

B SHOWN

[C1] CORNER PART

INSERT THE CORNER PART B INTO

TO THE

。?

MARK HOLE

[C2] CORNER PART B

BACK

FRONT

THE POSITIONS OF SHAFT AND ARM REFER TO ABOVE PIC.

PLACE FOR ARM

CAUTION THE WAY OF BACK AND FRONT

PLACE FOR CORNER

FOR EXAMPLE: FOLLOWING THE

。?

MARK INSERT CORNER PART

INTO SHAFT

ヘシ11

FIX THE SHAFT, ARM AND CORNER PART.

3

PLACE FOR ARM AND CORNER PART

PIC.11

MAKE A MARK ON THE SHAFT WITH PEN AS

SHOWN IN THE PICTURE

(MAKE ADJUSTMENTS AFTER INSTALLING)

THE

PIC.11

IS 1:1 SCALE TO THE SHAFT. SO

INSTALL THE ARM AND CORNER PART REFER

THE

。?MARK PLACE AND WAY ON PIC .

A

~

E

GEAR BOX STAND

WHEN INSERT THE ELEVATOR INTO THE BASE,

PLEASE LOCK THE GEAR BOX STAND ON THE

ELEVATOR BOTTOM TO KEEP BALANCE

HOW TO INSTALL RAIL STAND

2

[A6] RAIL STAND

1

[A6] RAIL STAND

07

[C1]

[C1] CORNER PART A

[C2]

[C2] CORNER PART B

08

SET THE RAIL STAND INTO THE

FORK PARK AS

PIC.08

SHOWS

[L1] LOOP PART

09

SET THE RAIL STAND INTO

THE LOOP PARK AS

PIC.08

SHOWS

TURN HANDGRIP OF ARM WRENCH TO AVOID INTERFERING WITH THE ROUTE

2

THE WAY TO INSTALL THE ARM INTO SHAFT

PIC.10

POSITION REFER

PIC.11

UNLOCK THE ARM BEFORE ADJUSTING

THE ROUTE OR THE ARM ANGLE.

INSERT THE SHAFT INTO ARM HOLDER B AND TURN

90-DEGREES TO LOCK IT AS

PIC.10

SHOWN

サキミホナ莨™

LOOP PART

ノ©スオフィ

ELEVATOR

A B

C

D

E

12

INSERT INTO THE HOLE ON BASE

[G1] GEAR BOX

[G2] GEAR BOX STAND

BACK

FRONT

[L1] LOOP PART

13

。LOOP STAND

PIC.13

[L2] LOOP STAND

INSERT INTO THE

HOLE ON BASE

BASE, SHAFT ,GEAR BOX, LOOP PART POSITION

4

。 PLACE ON THE BASE FOR SHAFT

PIC.14

INSERT THE SHAFT

PIC.11A

~

E

INTO THE BASE

PIC.14 A

~

E

。PLACE ON THE BASE FOR GEAR BOX

PIC.14

INSERT THE 3 CLIPS ON GEAR BOX BASE

PIC.12

INTO THE BASE

PIC.14

。INSERT THE LOOP INTO THE BASE

PIC.14

INSERT THE LOOP STAND

PIC.13

INTO THE BASE

PIC.14

OFF

ON

PUSH

LOOP PART

ELEVATOR

FIX THE GEAR BOX STAND HERE

14

BACK

B

D

FRONT

INSTALL THE ELEVATOR RING AS

PIC.06

SHOWS

06

[A4] ARM HOLDER B

INSTALLING THE SIDE ON SHAFT

[A2] ARM STAND A

INSTALLING THE SIDE ON ARM

[A5] ARM WRENCH

[A3] ARM SHEATH

[A1] ARM

CAUTION: ARM HOLDER A IS DIFFERENT

TO ARM HOLDER B

REPEAT 5 TIMES IN TOTAL

2

02

03

HOW TO INSTALL THE ARM

PIC02

PIC03

INSTALL THE ARM AS

PIC.02

SHOWS

PLACE THE ARM BETWEEN THE GAP IN ARM A & INSERT ARM WRENCH

TO LOCK, ROTATE 90’ ANTI-CLOCKWISE

UNLOCK THE ARM BEFORE ADJUSTING THE ROUTE

OR THE ARM ANGLE

INSERT THE ARM WRENCH INTO THE ARM HOLDER A AND TAKE A

90-DEGREE TURN TO LOCK IT AS

PIC.03

03

3

HOW TO INSTALL THE ELEVATOR

PIC

04-1 PIC

04-6

INSERT THE 300mm SHAFT INTO

GEAR BOX AS

PIC04-1

SHOWN

INSERT 3 SHAFTS INTO THE ELEVATOR

RING TO FIX IT, BE CAREFUL OF

THE RING WAY

PIC 04-4

REFER TO

PIC.06

FOR THE POSITION

OF THE RING. CAREFULLY CLIP THE 3 SHAFTS

INTO THE ELEVATOR RING

INSERT ELEVATOR OVER THE 4 SHAFTS

AS SEEN IN DIAGRAM ,

PIC.04-5

INSERT THE RAIL STAND OVER

THE PROTRUDING FORKS

AS SHOWN IN

PIC.04-6

[E3] ELEVATOR COVER

ヘシ04-5

ヘシ04-6

[A6] RAIL STAND

[A6] RAIL STAND

[S1] SHAFT 300mm

[G1] GEAR BOX

NOTE: THE ELEVATOR HELIX SHOULD

FIT FIRMLY ON THE WHITE WASHER.

CAUTION THE PART WAY

04-2

[E1] ELEVATOR HELIX

[S1] SHAFT 300mm

04-3

RED PART ON THE PIC, CONVEX SIDE UP,

CAUTION THE PART WAY WHEN INSERTTING

04-4

[E2] ELEVATOR RING

[E2] ELEVATOR RING

AIM TO THE ELEVATOR RING

PIC.06

SAMPLE

SHOWN

THE STEEL BALL WILL FLIP OUT IT'S ORBIT IF THE

SPEED OF ENTERING INTO ELEVATOR TOO FAST

ヘシ05

ELEVATOR STAND

ELEVATOR RING

HOW TO INSTALL THE ELEVATOR STAND

4

05

INSERT THE ELEVATOR STAND INTO

THE RING (

PIC.05

)

TOOLS FOR INSTALLING

PLIERS

PEN

PARTS LIST

USE 1 X C 1.5V BATTERY (NOT INCLUDED)

[B3] BASE HOLDER (SMALL)

[B2] BASE HOLDER (BIG)

[B1] BASE

01-1

1-2

1

HOW TO INSTALL

1. ASSEMBLE 3 BASES TOGETHER AS

PIC.01-2

(be careful of the position of clip and hole)

2. SET THE BASE HOLDER INTO THE

RELATING POSITION

PIC.01-1

1

3PCS

[A4] ARM HOLDER B

5PCS

[L1] LOOP PART

1PCS

[L2] LOOP STAND

1PCS

[C3] CORNER STAND

6PCS

[C2] CORNER PART B

3PCS

[R2] RAIL JOINT

2PCS

STEEL BALL

2PCS

[B3] BASE HOLDER (SMALL)

2PCS

[B2] BASE HOLDER (BIG)

2PCS

[G2] GEAR BOX STAND

1PCS

[P1] FORK PART

1PCS

[G1] GEAR BOX

1PCS

[E1] ELEVATOR HELIX

12PCS

[E2] ELEVATOR RING

3PCS

[E4] ELEVATOR STAND

3PCS

[C1] CORNER PART A

3PCS

[E3] ELEVATOR COVER

1PCS

[A6] RAIL STAND

29PCS+

[B1] BASE

[R1] RAIL (about 500mm)

1PCS

[A1] ARM

5PCS

[A2] ARM HOLDER A

5PCS

[A3] ARM SHEATH

5PCS

[A5] ARM WRENCH

10PCS

9PCS

[S1] SHAFT 300mm

Do not hold the elevator whilst the motor is running to prevent overheating.

It is recommended that after continuous play for 5 hours to turn your Space Coaster off to prevent overheating.

CAUTION

Always read instructions before use.

Please recycle all packaging.

Be careful of sharp edges when assembling.

When the elevator begins to slow replace the batteries.

Adjusting the rail regularly is necessary to continue

smooth operation.

Do not leave your Space Coaster in hot climates for a

prolonged period of time.

NOTE

Recommended for ages 14+

Keep small parts away from children to prevent choking.

Be careful of all sharp edges or corners.

Do not bend the base or metal rods included.

Do not place fingers in, around or near the ball elevator when in use.

Do not place any other items into the elevator except the balls provided.

Do not force the motor to stop to prevent overheating.

Store away safely when not in use.

Do not use re-chargeable batteries.

Ensure batteries are inserted with the correct polarity.

NOTE: THE PIECES OF THE ELEVATOR

HELIX SHOULD FIT FIRMLY TOGETHER

ASSEMBLE THE 12 PIECES OF THE ELEVATOR HELIX

TOGETHER. SLIDE THE BUILT ELEVATOR HELIX OVER

THE SHAFT

PLACE THE 3 300mm SHAFTS INTO THE

3 HOLES IN THE GEAR BOX.

INSERT THE RAIL STAND ONTO THE PROTRUDING

FORKS OF THE FORK PART AS SHOWN IN

PIC.07

FIX THE ARMS & CORNER PARTS ON THE 5

SHAFTS

- THIS PICTURE REPRESENTS A 1:1 SCALE

OF THE SHAFT SHOWING THE POSITIONS OF

THE ARMS & CORNER PARTS.

PLEASE NOTE, UP/DOWN/LEFT/RIGHT

FIX THE GEAR BOX STAND ONTO THE ELEVATOR STAND

& THEN FIX ONTO THE BASE AS SHOWN IN THE DIAGRAMS

FIX THE LOOP STAND TO THE LOOP PART &

INSERT ONTO BASE

NOTE FRONT AND BACK OF THE LOOP

BEFORE INSERTING LOOP STAND.

INSERT SHAFTS, GEARBOX & LOOP STAND INTO POSITION AS SHOWN IN

DIAGRAM

TAKE CARE OF FINGERS WHEN INSERTING.

INSERT THE RAIL STANDS ONTO THE PROTRUDING

FORKS OF THE LOOP PART AS SHOWN

SLIDE SHAFT INTO THE ARM HOLDER B (PREVIOSULY MADE)

& LOCK WITH AN ARM WRENCH.

NOTE: POSITION SHOULD BE CORRECT BEFORE LOCKING

REFER TO DIAGRAM FOR CORRECT POSITION

Space Coaster

thumbsUp! (UAE)

Best Homes Business Center

M 107, Mezzanine Floor

Sheik Zayed Road

Dubai, UAE

T: +971-4-3465465

F: +971-4-3388826

Mail: [email protected]

Web: www.thumbsup.ae

thumbsUp! (BR)

Departmento Comercial

Rua Henrique Jorge Guedes 127Jardim

Marajoara

Sao Paulo, Brazil

T: +55 11 2275 1978

F: +55 11 9219 9375

www.thumbsup.br.com

thumbsUp! (FR)

164 av Joseph Kessel,

78960 Voisin le

Bretonneux, FR

T: +33 (0)1 61 37 02 90

F: +33 (0)1 61 37 03 05

www.thumbsup.fr

thumbsUp! (USA)

thumbsUp! USA, 841-B

Fesslers Parkway, Nashville,

TN 37067, USA

T: 615-620-1370

F: 615-620-1371

www.thumbsupusa.com

thumbsUp! (AUS)

Unit 1, 113 Broadway,

Bassendean, WA 6054

Australia

T: 1300 873 637

F: 1300 304 870

Mail: [email protected]

Web: www.thumbsupaus.com

thumbsUp! (DE)

thumbsUp! GmbH

Speestr. 24

53840 Troisdorf, DE

T: +49 2241 972 507-0

F: +49 2241 972 507-88

www.thumbsup.de

thumbsUp! (UK)

Santok House, Unit L, Braintree Industrial Estate

Ruislip, Middlesex, HA4 0EJ, UK

Tel: 0845 466 8880

Fax: 0845 466 8881

www.thumbsupuk.com

Head Office

Made in China

SPCCOAS-GLOW