2 tightening torques, 3 flow rates, 4 minimum differential pressures – Richter BCV/F (ASME) Series Check Valves User Manual

Page 4: Tightening torques, Flow rates, Minimum differential pressures, Series cv/f, cvv/f, bc/f, bcv/f

Series CV/F, CVV/F, BC/F, BCV/F

Page 4

9550-050-en

Revision 10

TM 8462

Edition 02/2012

Body identification:

The following are visible on the body according to DIN

EN 19 and AD 2000 A4:

Nominal size

Rated pressure

Body material

Manufacturer's identification

Melt number/Foundry identification

Cast date

Arrow for direction of flow

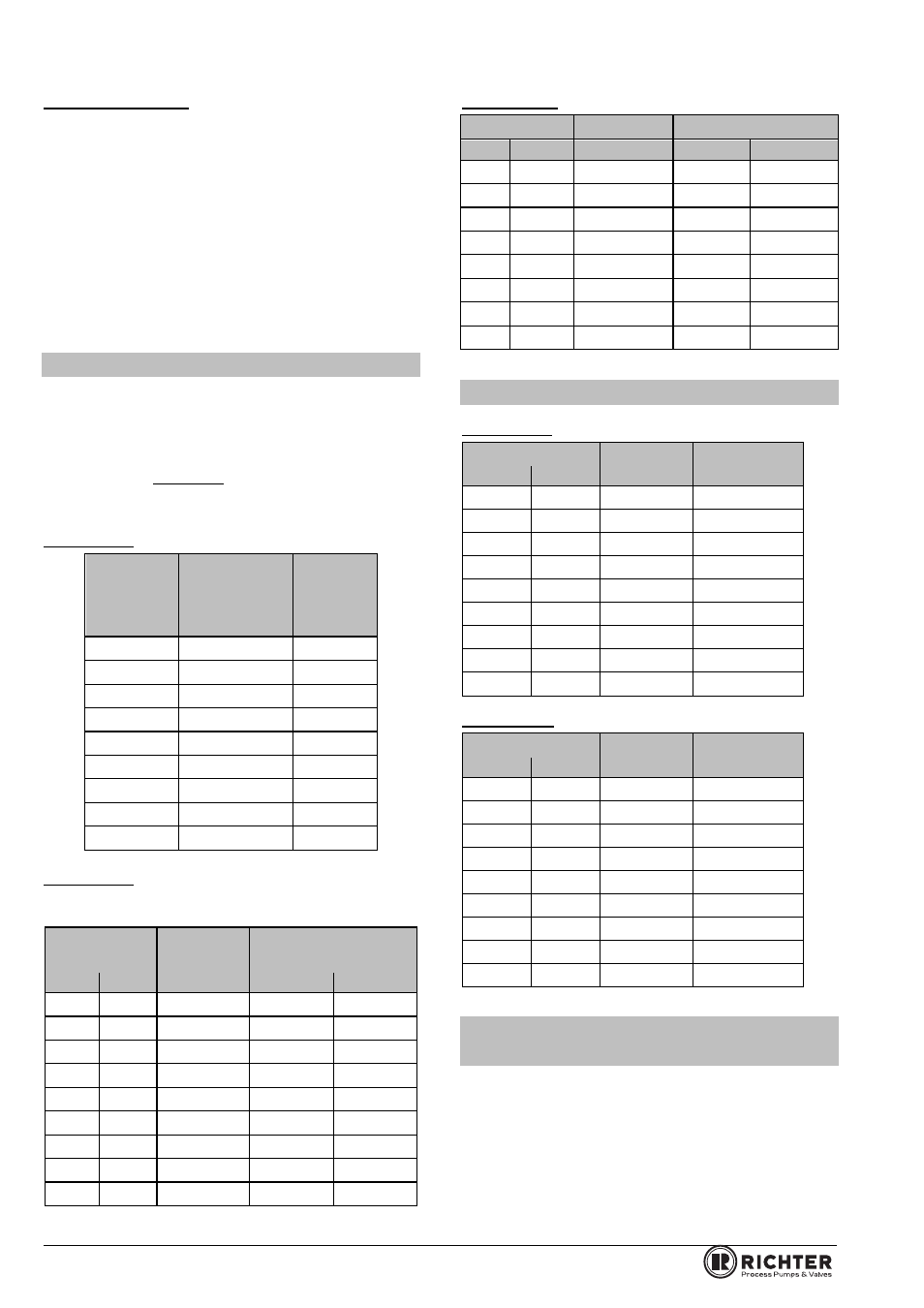

1.2 Tightening torques

All screws greased, tighten in diametrically

opposite sequence!

The tightening torques for pipe screws and body

screws mentioned must not be exceeded. For an

exception, see Section 8, Flange connection valve /

pipe is leaking.

The following tightening torques are recommended.

Pipe screws, flanges to ISO/DIN

Flange

Nominal

size

Screws

Tightenin

g torque

moment

[mm]

[ISO/DIN]

[Nm]

15

4 x M 12

6

20

4 x M 12

8

25

4 x M 12

10

40

4 x M 16

20

50

4 x M 16

26

65

4 x M 16

40

80

8 x M 16

25

100

8 x M 16

35

150

8 x M 20

65

Pipe screws, flanges to ISO/DIN drilled to ASME

Class 150 or flanges ASME B 16.5 Class 150, raised

face

Flange

Nominal size

Screws

Tightening torque

[mm]

[inch]

[ASME]

[in-lbs]

[Nm]

15

½

4 x ½“

45

5

20

¾

4 x ½“

55

6

25

1

4 x ½“

70

8

40

1½

4 x ½“

135

15

50

2

4 x O“

220

25

65

2½

4 x O“

265

30

80

3

4 x O“

400

45

100

4

8 x O“

310

35

150

6

8 x ¾“

710

80

Body screws

Nominal size

Screws

Tightening torque

[mm]

[inch]

[ISO/DIN]

[in-lbs]

[Nm]

15

½“

4 x M 12

220

25

20

¾“

4 x M 12

220

25

25

1“

4 x M 12

220

25

40

1½“

4 x M 16

442

50

50

2“

4 x M 16

442

50

65

3“

8 x M 16

442

50

80

4“

8 x M 16

442

50

100

6“

8 x M 16

442

50

1.3 Flow rates

CV/F, CVV/F

Nominal size

Cv

Kv 100

[mm]

[m3/h]

15

½“

7.3

8.5

20

¾“

13.7

16

25

1“

23.2

27

40

1½“

83.4

97

50

2“

105

122

65

2½“

49

57

80

3“

258

300

100

4“

353

410

150

6“

310

330

BC/F, BCV/F

Nominal size

Cv

Kv 100

[mm]

[m3/h]

15

½“

7.3

8.5

20

¾“

13.7

16

25

1“

19

22

40

1½“

54

61

50

2“

79

92

65

1½“

--

--

80

3“

172

200

100

4“

310

360

150

6“

310

330

1.4 Minimum differential

pressures

Installation position

horizontal

vertical

CV/F

1 bar

20 mbar

CVV/F

0,5 bar

10 mbar

BC/F

15 psi

0,30 psi

BCV/F

7 psi

0.12 psi

If the CVV/F/BCV/F is installed as ventilation valve, it

will close from a density of 1 kg/dm

3

upwards.