8 malfunctions, 9 maintenance, 1 demontage – Richter GR/F Series Check Valves User Manual

Page 9: 1 replacing plug, 2 replacing seat, 2 montage, 1 replacing, Plug, 2 replacing, Seat

Series GR/F

Page 9

9550-075-en

Revision 01

TM 6897

Edition 10/2007

8

Malfunctions

Flange connection valve/pipe is leaking

Retighten the flange screws to a tightening torque

according to Section 1.2. If this does not remedy

the leak, the recommended torques may be

exceeded by 10%.

If this also fails to stop the leak, dismantle and

inspect the valve.

Flange connection main body/body end piece is

leaking

Retighten body screws. See paragraph "Flange

connection ball valve/pipe is leaking".

Valve does not close

Are there solids between the sealing surface and

the ball?

Is the sealing surface damaged?

Is the ball damaged?

9

Maintenance

All repair work is to be performed by qualified

personnel using the appropriate tools. Generally

recognised practice in mechanical engineering is to

be observed.

For the arrangement, designation and item

numbers of all parts of the valve, see Section 10.

Spare parts are to be ordered with all the details in

acc. with the valve identification.

Only original spare parts may be installed.

To prevent leaks, a regular check of the connection

screws should be made in line with the operating

requirements.

For torques see Section 1.2.

9.1 Demontage

9.1.1 Replacing plug

Remove cover screws 901/1, 936/1 (with DN 100

902/2, 936/1, 920/3).

Pull guide 801 with shank 808 and valve plug 204

out of the body 100.

DN 25-100

Pull round cord 522 with pliers out of the valve plug

204.

Replace valve plug 204.

Check to see whether the seat 205 is still OK:

If not: Replace. See Section 9.1.2.

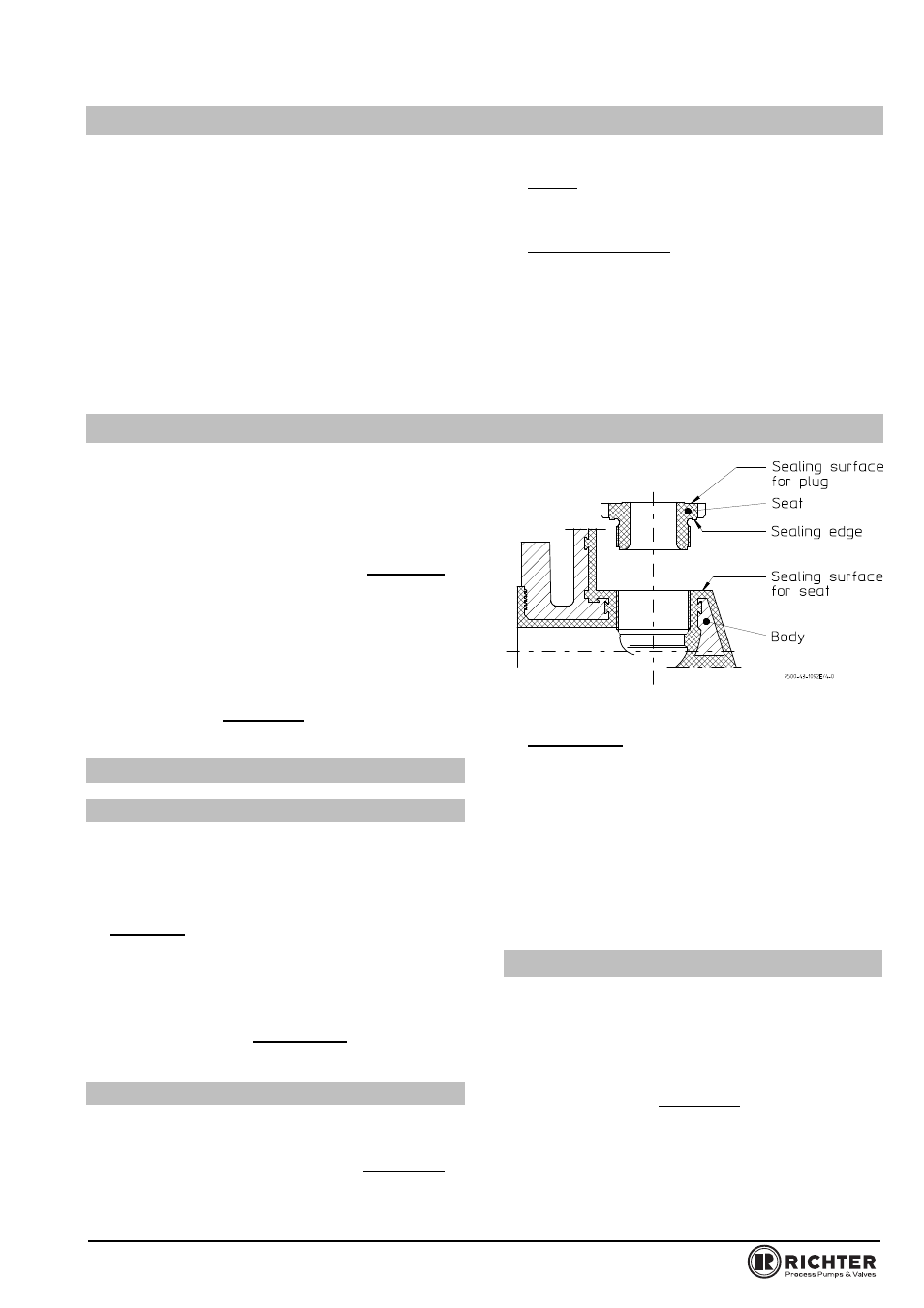

9.1.2 Replacing seat

A screw-in tool is required for the assembly and

dismantling of the seat 205. The article numbers for

the individual nominal sizes are listed in Section 1.3.

The new seat must be carefully protected prior to

assembly. The sealing edge and the sealing surface

for the plug must not be damaged.

Remove the upper part of the valve as described in

Section 9.1.1.

Screw the seat 205 out of the body with the Richter

screw-in tool. Right-hand thread.

Carefully clean the sealing surface in the body 100

and check for damage.

If there is any damage, you can try to rework the

sealing surface.

Screw the new seat 205 without lubricant into the

body using the Richter screw-in tool.

9.2 Montage

Assembly is performed in reverse sequence.

Prior to assembly all parts must be cleaned and the

plastic-lined parts checked for damage.

Bolt body 100 and cover 106 together. Tighten the

screws in diametrically opposing sequence to a

torque indicated in Section 1.2.