5 transport and storage, 1 storage, 2 return consignments – Richter KAP-N Series Bottom Drain Ball Valves User Manual

Page 7: 6 installation, 1 flange caps and gaskets, 2 direction of flow and installation position, Transport and storage, Storage, Return consignments, Installation

Installation and Operating Manual

Series KA-N, KAP-N,

ball and stem

9520-067-en

Revision 00

TM 6404 MPE/Wm

Page 7

Edition

02/2006

4

Safety note for valves, certified to Clean Air Act (TA-Luft)

Certificate / Manufacturer Declaration Validity is

dependent on the operating instructions being read

and observed.

In particular, servicing must be conducted at regular

intervals, and the bolted connections relevant for

tightness must be inspected and retightened if

necessary.

5

Transport and storage

It is imperative, for all transport work, to

observe generally accepted engineering

practice and the accident prevention

regulations.

The valve is supplied with flange caps. Do not

remove them until just before installation.

They protect the plastic surfaces against dirt

and mechanical damage.

Handle the goods being transported with care. During

transport the valve must be protected against impacts

and collisions.

Directly after receipt of the goods, the consignment

must be checked for completeness and any in-transit

damage.

Do not damage paint protection.

5.1 Storage

If the valve is not installed immediately after delivery, it

must be put into proper storage.

It should be stored in a dry, vibration-free and well-

ventilated room at as constant a temperature as

possible.

5.2 Return

consignments

Valves which have conveyed aggressive or

toxic media must be well rinsed and cleaned

before being returned to the manufacturer's

works.

A General Safety Certificate on the field of applica-

tion is to be enclosed with the returned goods.

Pre-printed forms are enclosed with the installation

and operating manual.

Safety precautions and decontamination measures

are to be mentioned.

6

Installation

Examine valve for in-transit damage, damaged valves

must not be installed.

Before installation the valve and the connecting pipe

must be carefully cleaned to remove any dirt,

especially hard foreign matter.

During installation, pay attention to the correct

tightening torque, aligned pipes and tension-free

assembly.

6.1 Flange caps and gaskets

Leave protective caps on the flanges until just prior to

installation.

Where there is a particularly high risk of damage to

the plastic sealing surfaces, e.g. if the mating flanges

are made of metal or enamel, PTFE-lined gaskets with

a metal inlay should be used. These gaskets are

available as special accessories in the Richter range.

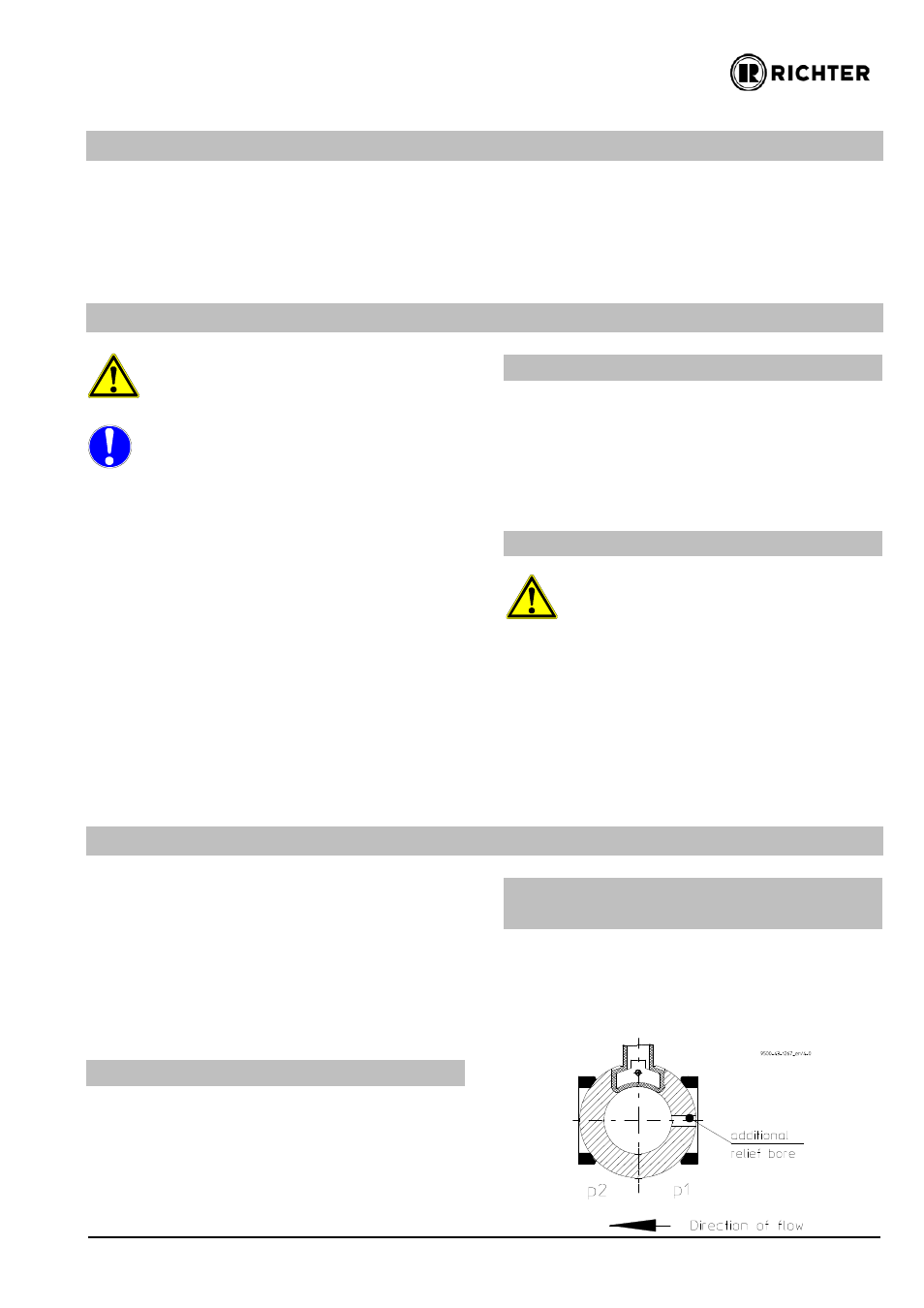

6.2 Direction of flow and installa-

tion position

Installation is independent of the direction of flow.

Any installation position can be chosen.

Otherwise, it is marked by a direction arrow on the

bottom drain ball valve, e.g. in the case of an

additional relief bore in the ball.