1 technical data, Echnical data, E test pressure – Richter GUT/F Series Overflow Valves User Manual

Page 3: 1technical data, Series gut/f

Series GUT/F

Page 3

9530-071-en

Revision 10

TM 8361

Edition 10/2011

1

Technical data

Manufacturer :

Richter Chemie-Technik GmbH

Otto-Schott-Str. 2

D-47906 Kempen

Telephone: +49 (0) 2152 146-0

Fax:

+49 (0) 2152 146-190

E-Mail:

Internet:

http://www.richter-ct.com

Designation :

Series GUT/F, overflow and pressure relief valve with

an inline body.

They are direct-acting and spring-loaded and

classified as standard valves as regards their opening

characteristic.

Standard overflow valve, design and operation to

German AD data sheet A2 (on pressure vessels), ISO

4126

Certified to Clean Air Act (TA Luft)

Strength and tightness (P10, P11) of the pressure-

bearing body tested to DIN EN 12266-1.

Gas-tight (P12) in the seat to DIN EN 12266-1,

leak rate A

Face to face alternatively:

DIN EN 558-1 basic series 1, ISO 5752 series 1

with flanges DIN EN 1092-2, type B

(ISO 7005-2 Type B) PN 16 or flanges drilled to

ASME B16.5 Class 150

ANSI/ISA-75.08.09-2004, class 150 with flanges

ASME B16.5 Class 150, raised face

ANSI/ISA-75.08.09-2004, class 300 with flanges

ASME B16.5 Class 300, raised face

Materials :

Body material: Ductile cast iron EN-JS 1049 or ASTM

A395

Lining material: PFA/PTFE

.../F

On request: antistatic PFA-L

…/F-L

highly permeation-resistant …/F-P

Ultrapure PFA-HP

…/F-HP

Bellows:

PTFE

Seat and Plug: modified PTFE

Option unmodified PTFE, Hastelloy

Temperature range :

-60 °C to 180 °C

See pressure-temperature diagram in Section 1.4.

Valve size in mm

DN 25 in mm

1“ in Zoll, Cl 150

1“, in inches, Cl 300 on request

Weight :

approx. 10,5 kg

Installation position :

A direction arrow on the shell indicates the direction of

flow. See Section 6.5.

Dimensions and individual parts :

Please pay attention to the drawing in Section 10.

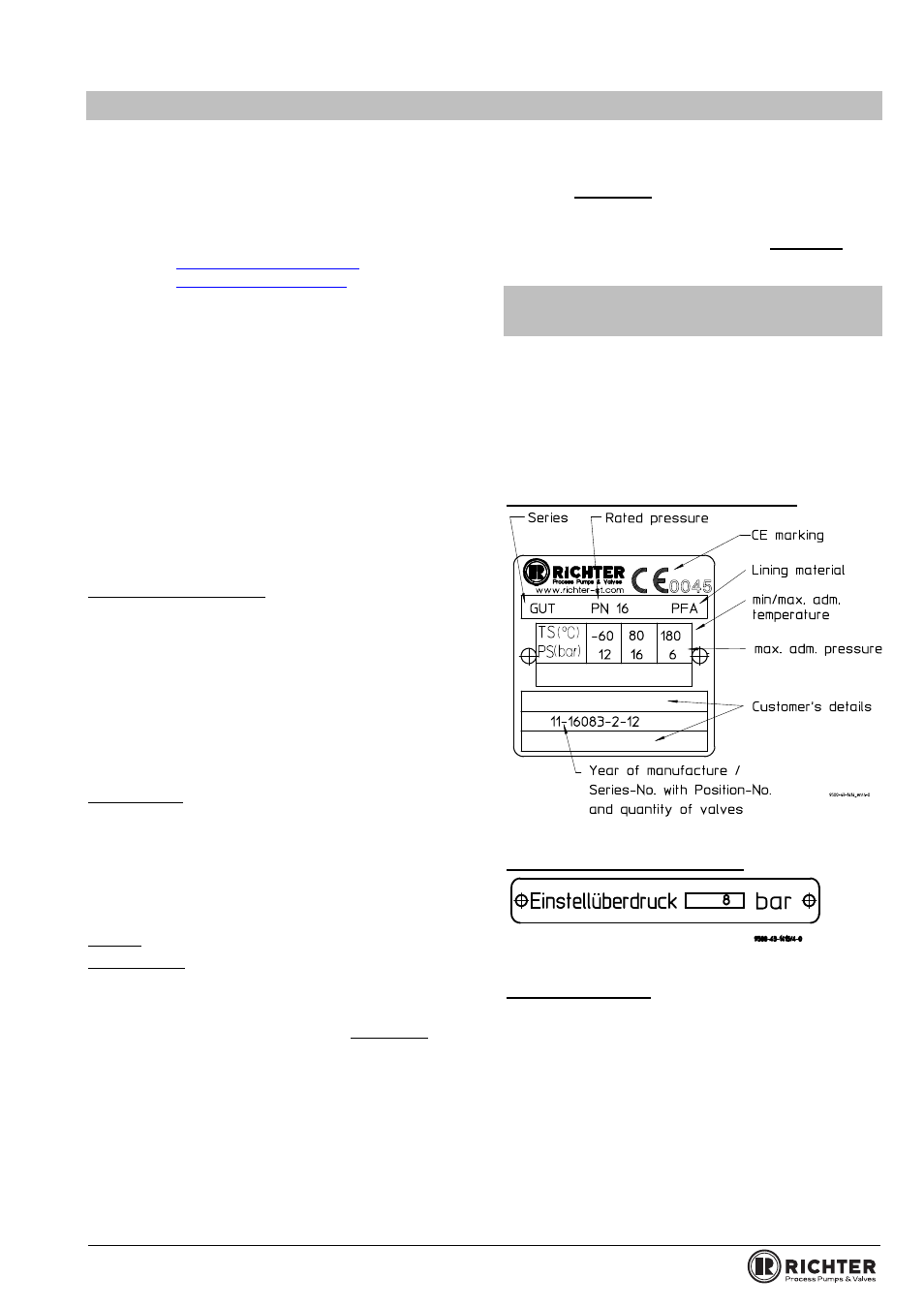

1.1 Type plate, CE and body

markings, plate test pressure

The stainless steel name plate is undetachably

riveted to the body.

Another stainless steel tag plate riveted to the valve

indicates the test pressure.

If the operator attaches his identification, it must be

ensured that the valve matches the application in

question.

Example of type plate with CE marking:

Example: Plate for test pressure

Body identification:

The following are visible on the body according to DIN

EN 19 and AD 2000 A4:

Nominal size

Rated pressure

Body material

Manufacturer's identification

Melt number/Foundry identification

Cast date

Arrow for direction of flow